1

SECTION I - GENERAL INFORMATION (Continued)

A.

INSPECT SHIPMENT carefully for any signs of

damage.

1. ALL EQUIPMENT is carefully manufactured,

inspected and packed. Our responsibility ceases

upon delivery of crated Boiler to the carrier in good

condition.

2. ANY CLAIMS for damage or shortage in shipment

must be filed immediately against the carrier by

the consignee. No claims for variances from,

or shortage in orders, will be allowed by the

manufacturer unless presented within thirty (30)

days after the receipt of goods.

B.

LOCATE THE UNIT

NOTICE

Recommended clearance for service may be

reduced to minimum clearance to combustible

material.

However,

increased

service

and

maintenance difficulty will result.

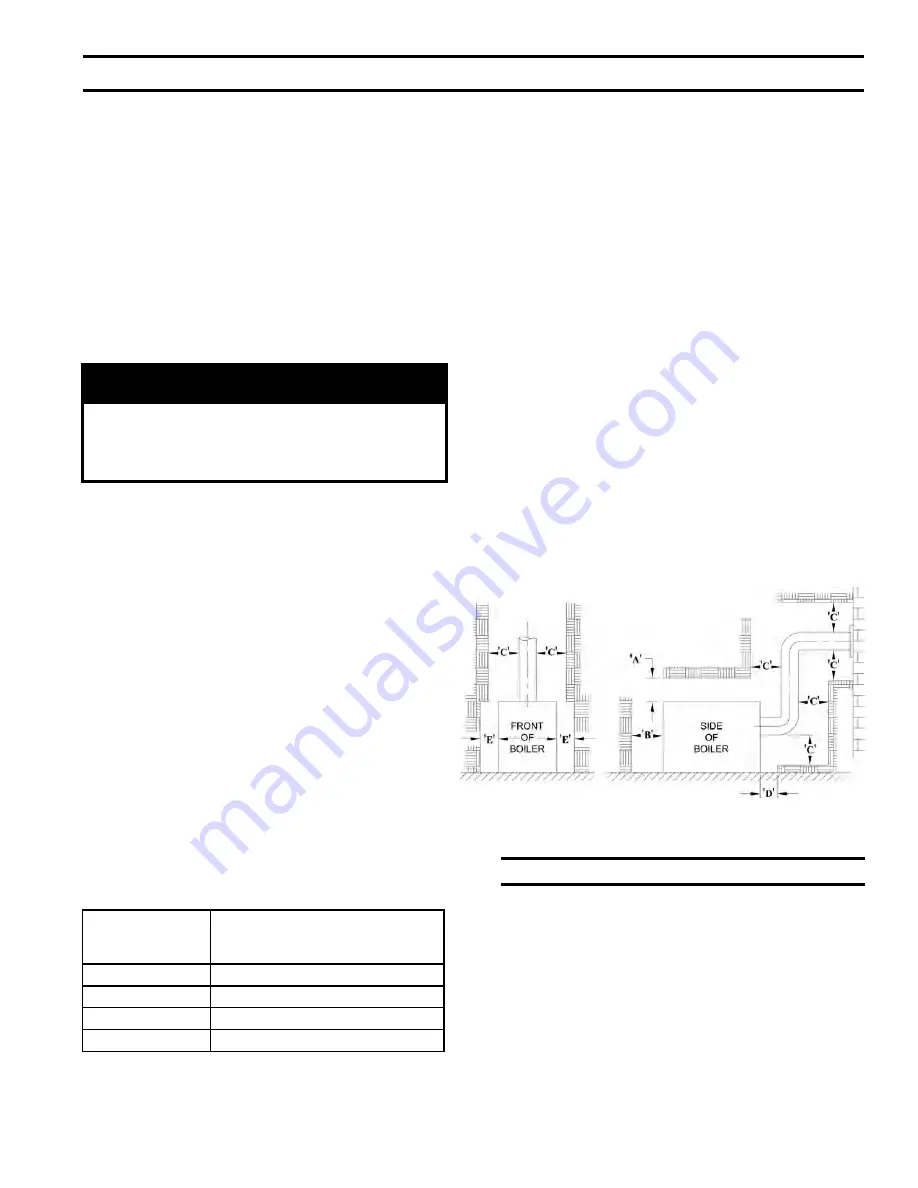

1. RECOMMENDED SERVICE CLEARANCE

- Locate the unit in the boiler room so as to

provide ease of venting and adequate clearance

for maintenance, serviceability, and installation of

piping. Refer to Figure 1b and Table 1 for boiler

dimensional data.

from Jacket front Panel

:

•

Provide 54” service clearance for removal,

maintenance, and servicing of burner and

controls.

•

Provide service clearance for removal

of baffles to perform annual cleaning of

flueways, refer to Table I, Dimension “C”.

from Jacket Rear Panel

:

•

Provide a minimum service clearance from

the boiler jacket for access to boiler supply

and return piping, relief valve, drain valve,

flue collector clean-out covers, vent piping

and optional flue damper assembly. See

Table III.

Table IV: Minimum Installation Clearances To

Combustible Materials (Inches) per

ANSI/NFPA 1 (Knockdown/Non-UL

Packaged Boiler)

C

A

B

Chimney

D

E

Boiler

Above

Front

Connector

Rear

Sides

MPC

6

24

18

6

6

Note:

See Table III for recommended service clearance

to access rear of boiler.

from Jacket Left side Panel

:

•

Provide clearance per Table I, Dimension

‘B’, for burner swing door (BSD), opened

fully with burner mounted, otherwise 12”

with burner removed.

•

18” access clearance to service rear of boiler

if right side clearance is less than 12”.

•

12” minimum if right side clearance is 18”

or larger to access and service rear of boiler.

from Jacket Right side Panel

:

•

See Table I, Dimension ‘B’ if BSD is

hinged to swing to right side with burner

mounted, otherwise 12” minimum if left

side clearance is 18” or larger to access and

service rear of boiler.

from Jacket Top Panel

:

•

Provide a minimum clearance from the

boiler jacket of 24”.

2. FOR MINIMUM CLEARANCES to combustible

materials, See Table IV or Table V.

NOTE 1: Listed clearances comply with American National

Standard ANSI/NFPA 31, Installation of Oil Burning Equipment.

NOTE 2: MPC Series boilers can be installed in rooms with

clearances from combustible material as listed above. Listed

clearances cannot be reduced for alcove or closet installations.

NOTE 3: For reduced clearances to combustible material,

protection must be provided as described in the above ANSI/NFPA

31 Standard.

Table III: Recommended Rear Service Clearance

Flue Outlet Size

Combustible or Non-Combustible

Surfaces

7” Dia.

36

8” Dia.

36

10” Dia.

36

12” Dia.

36

Содержание MPC

Страница 19: ...19 Figure 5 Manual or Hydraulic Draw up Section Assembly ...

Страница 28: ...28 Table VII Modular Return Water Mixing Tube RWMT RC ...

Страница 29: ...29 Figure 13 Return Water Mixing Tube RC Assembly and Installation ...

Страница 78: ...78 Figure 56 MPC Common Bare Boiler Components ...

Страница 80: ...80 Figure 56 MPC Common Bare Boiler Components continued ...

Страница 82: ...82 Figure 57 MPC Front Center Section Frame Rail Assembly ...

Страница 84: ...84 Figure 58 MPC Rear Section Frame Rail Assembly ...

Страница 86: ...86 Figure 59 MPC Return Water Mixing Tube RC Assembly ...

Страница 88: ...88 Figure 60 MPC Heat Exchanger Insulation Wrapper ...

Страница 90: ...90 Figure 61 MPC Internal Wiring Harness Components ...

Страница 92: ...92 Figure 62 MPC Jacket Panel Assembly ...

Страница 94: ...94 Figure 62 MPC Jacket Panel Assembly continued ...

Страница 96: ...96 Figure 63 MPC 2 nd and 3 rd Pass Flueway Baffles ...

Страница 98: ...98 Figure 64 MPC Standard 50 PSI Trim Control with 30 PSI and 80 PSI Working Pressure Trim Options ...

Страница 100: ...100 Figure 64 MPC Standard 50 PSI Trim and Control with 30 PSI and 80 PSI Working Pressure Trim Options continued ...

Страница 102: ...102 Figure 65 MPC Optional Controls ...