7

Placing the heating system in operation

Logano plus GB312 – 6 720 806 273 (2013/01)

36

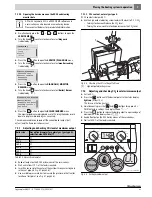

7.12.1 CO

2

content, natural gas type A (minimum output)

If CO

2

content is below 9,0 % or above 9,5 %.

▶ Use the low-output adjusting screw to adjust the level to 9,1 % CO

2

.

– Turning the screw clockwise increases the CO

2

level.

– Turning the screw counter-clockwise reduces the CO

2

level.

7.12.2 Reading off and comparing CO

2

levels

▶ After reading off the CO

2

level or adjusting it on the Monitor readings/

Burner menu, read off the flame ionization current and compare with

the specified levels.

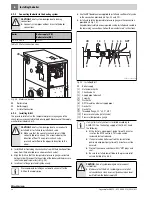

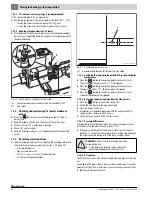

Fig. 46 Checking CO

2

setting at medium output

[1]

Low-output adjusting screwGas valve: Honeywell V4730C

[2]

Cap screw

7.13

Checking and monitoring CO

2

level at maximum

output

▶ Press the

button to increase the boiler output to a higher

percentage.

▶ Read off output on the RC35 or by means of the service keys.

▶ Wait until at least 70 % of the load is reached.

▶ Check CO

2

content again.

▶ Read off flame ionization current (and compare with the specified

levels).

7.14

Recording measured values

▶ Take the following readings at a test point on the vent pipe and record

them in the commissioning report (

Section 7.20, page 39):

– Pressure differential

– Flue gas temperature t

A

– CO

2 level or oxygen content

(O

2

) (Carbon Dioxide)

– CO content (Carbon Monoxide)

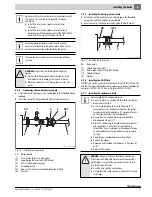

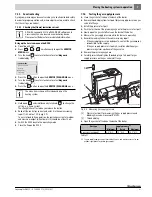

Fig. 47 Recording measured values

[1]

Recommended location for test point on vent pipe

7.14.1 Switching the status display on the BC10 to show the boiler

temperature

▶ Press the

button to change the display to the next status.

The current operating pressure

is displayed.

▶ Press the

button to change the display to the next status.

The operating status

(display code) is displayed.

▶ Press the

button to change the display to the next status.

The boiler temperature is displayed.

7.14.2 Returning to operating mode from the flue gas test

▶ Press the

button to cancel the flue gas test.

▶ Switch the RC35 back to the operating mode.

▶ Close the flap on the RC35.

▶ If the boiler is intended for operation with the Logamatic 4000

control system, remove the RC35 again.

▶ Switch on the Logamatic 4000 control system.

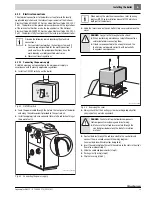

7.14.3 Pressure differential

The required pressure differential for the flue gas/air supply system

installed must not be greater than 0.4 inches W.C.

▶ If the pressure differential at maximum output is higher than 0.4

inches W.C., contact the flue system planner responsible and check

the calculations and design of the flue gas/air supply system.

7.14.4 CO content

The CO content in an air-free state must be below 400 ppm or 0.04% by

vol.

Levels above 100 ppm indicate incorrect burner adjustment, incorrect

appliance settings, dirt in the burner or heat exchanger or burner faults.

▶ Identify and eliminate the fault.

7 747 010 720-51.2RS

2

1

DANGER:

Risk of fatal injury due to poisoning by

escaping flue gas!

▶ Only operate the boiler in conjunction with a

connected and approved venting system.

7 747 010 720-60.1RS

1

Содержание Logano plus GB312

Страница 93: ...Logano plus GB312 6 720 806 273 2013 01 93 Notes ...

Страница 94: ...Logano plus GB312 6 720 806 273 2013 01 94 Notes ...

Страница 95: ...Logano plus GB312 6 720 806 273 2013 01 95 Notes ...

Страница 96: ......