9

Heating system inspection

Logano plus GB312 – 6 720 806 273 (2013/01)

47

9.7

Checking gas valve for leaks

The purpose of this procedure is to check the solenoid valves in the gas

valve for leaks. The test should only be carried out by trained and

experienced service technicians when servicing or replacing the gas

valve.

▶ Disconnect the boiler from the electrical power supply and unplug

the power plug from the gas valve.

▶ Turn off the gas shutoff valve A on the back of the boiler.

▶ Make sure that the manual shutoff valve E on the testing apparatus

(

Fig. 67, page 48) is turned off.

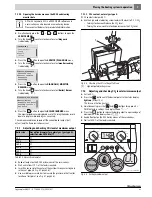

▶ To test the 1st solenoid valve (B), remove plug P from the gas valve

and install a test nipple.

▶ Open shutoff valve A to pressurize the 1st solenoid valve (B).

▶ Hold the end of a test capillary with a 1/4 inch internal diameter 1/2

inch below the surface in a glass of water.

▶ Slowly open the manual shutoff valve E on the testing apparatus.

▶ Once a stable flow of bubbles is escaping from the testing tube, the

number of bubbles in the space of 10 seconds must be counted. The

permissible number of bubbles is 6 (equates to 0.008 ft

3

/h) for

boiler sizes 90-4 to 240-7, and 7 (equates to 0.01 ft

3

/h) for boiler

size 280-8.

▶ Close gas shutoff valve A on the back of the boiler again.

▶ Remove the test nipple from test point P and carefully reinstall and

seal the plug with the aid of an appropriate sealant.

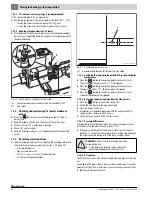

▶ To test the 2nd solenoid valve (C), remove the plug from test point 4

on the gas valve outlet flange and install a test nipple.

▶ Close gas shutoff valve D downstream of the gas valve.

▶ Remove the plug from test point 3 on the gas valve and install a test

nipple. Connect the hand pump G, which is part of the testing

apparatus, and connect a pressure tester H (

Fig. 67, page 48).

Use the hand pump H to carefully build up a test pressure of 7 inches

W.C. and then close shutoff valve F on the testing apparatus.

▶ Hold the end of a test capillary with a 1/4 inch internal diameter 1/2

inch below the surface in a glass of water.

▶ Slowly open the manual shutoff valve E on the testing apparatus.

▶ Once a stable flow of bubbles is escaping from the testing tube, the

number of bubbles in the space of 10 seconds must be counted. The

permissible number of bubbles is 6 (equates to 0.008 ft

3

/h) for

boiler sizes 90-4 to 240-7, and 7 (equates to 0.01 ft

3

/h) for boiler

size 280-8.

▶ Remove the test nipples from test points 3 and 4, and carefully

reinstall and seal the plugs with the aid of an appropriate sealant.

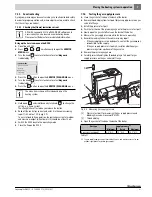

After completing the test, proceed as follows.

▶ Ensure that gas shutoff valve D on the outlet side of the gas valve is

closed.

▶ Reconnect the power plug to the gas valve and restore the power

supply to the boiler again.

▶ Open gas shutoff valve A on the back of the boiler again.

▶ Switch on the boiler and run the burner 1 start sequence.

▶ Use a suitable leak detecting agent to check all joints on the gas valve

for leaks. Open gas shutoff valve D on the outlet side of the gas valve

again. Reset the boiler to the normal operating mode.

DANGER:

Risk of fatal injury from electric shock.

▶ Disconnect boiler from the electrical power supply.

▶ Unplug the power plug from the gas valve.

CAUTION:

Risk of burner damage due to excessive

pressure when testing for leaks.

The gas pressure regulator and other gas valve

components can be damaged if the test pressure is too

high.

▶ On no account use a higher testing pressure than 7

inches W.C.

CAUTION:

Risk of system damage due to short-circuits!

▶ Cover the fan and other points at risk prior to

checking for leaks.

▶ Never apply leak detector spray to cable entries,

plugs or electrical cables/leads. Do not let it drip onto

them either.

Содержание Logano plus GB312

Страница 93: ...Logano plus GB312 6 720 806 273 2013 01 93 Notes ...

Страница 94: ...Logano plus GB312 6 720 806 273 2013 01 94 Notes ...

Страница 95: ...Logano plus GB312 6 720 806 273 2013 01 95 Notes ...

Страница 96: ......