41

ing on selection at blower--OFF delay switches). The

furnace control CPU is factory--set for a 120--second

blower--OFF delay.

2.

Cooling mode

The thermostat “calls for cooling”.

a.

Single--Speed Cooling

--

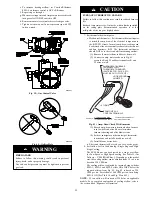

See Fig. 25 for thermostat connections

The thermostat closes the R--to--G--and--Y circuits. The

R--to-- Y circuit starts the outdoor unit, and the R--to--

G--and--Y/Y2 circuits start the furnace blower motor

BLWM on cooling airflow. Cooling airflow is based

on the A/C selection shown in Fig. 42. The electronic

air cleaner terminal EAC--1 is energized with 115 vac

when the blower motor BLWM is operating.

When the thermostat is satisfied, the R--to--G--and--Y

circuits are opened. The outdoor unit will stop, and the

furnace blower motor BLWM will continue operating

at cooling airflow for an additional 90 seconds.

Jumper Y/Y2 to DHUM to reduce the cooling off--de-

lay to 5 seconds. (See Fig. 23)

b.

Single--Stage Thermostat and Two--Speed Cooling

(Adaptive Mode)

See Fig. 28 for thermostat connections.

This furnace can operate a two--speed cooling unit

with a single--stage thermostat because the furnace

control CPU includes a programmed adaptive se-

quence of controlled operation, which selects low--

cooling or high--cooling operation. This selection is

based upon the stored history of the length of previous

cooling period of the single--stage thermostat.

NOTE

: The air conditioning relay disable jumper ACRDJ must

be connected to enable the adaptive cooling mode in response to

a call for cooling. (See Fig. 23) When ACRDJ is in place the

furnace control CPU can turn on the air conditioning relay ACR

to energize the Y/Y2 terminal and switch the outdoor unit to

high--cooling.

The furnace control CPU can start up the cooling unit in either

low-- or high--cooling. If starting up in low--cooling, the furnace

control CPU determines the low--cooling on--time (from 0 to 20

minutes) which is permitted before switching to high--cooling. If

the power is interrupted, the stored history is erased and the

furnace control CPU will select low--cooling for up to 20 minutes

and then energize the air conditioning relay ACR to energize the

Y/Y2 terminal and switch the outdoor unit to high--cooling, as

long as the thermostat continues to call for cooling. Subsequent

selection is based on stored history of the thermostat cycle times.

The wall thermostat “calls for cooling”, closing the

R--to--G--and--Y circuits. The R--to--Y1 circuit starts the outdoor

unit on low--cooling speed, and the R--to--G--and--Y1 circuits

starts the furnace blower motor BLWM at low--cooling airflow

which is the true on--board CF selection as shown in Fig. 42.

If the furnace control CPU switches from low--cooling to

high--cooling, the furnace control CPU will energize the air

conditioning relay ACR. When the air conditioning relay ACR is

energized the R--to--Y1--and--Y2 circuits switch the outdoor unit

to high--cooling speed, and the R--to--G--and--Y1--and--Y/Y2

circuits transition the furnace blower motor BLWM to

high--cooling airflow. High--cooling airflow is based on the A/C

selection shown in Fig. 42.

NOTE

: When transitioning from low--cooling to high--cooling

the outdoor unit compressor will shut down for 1 minute while

the furnace blower motor BLWM transitions to run at

high--cooling airflow.

The electronic air cleaner terminal EAC--1 is energized with 115

vac whenever the blower motor BLWM is operating.

When the thermostat is satisfied, the R--to--G--and--Y circuit are

opened. The outdoor unit stops, and the furnace blower BLWM

and electronic air cleaner terminal EAC--1 will remain energized

for an additional 90 seconds. Jumper Y1 to DHUM to reduce the

cooling off--delay to 5 seconds. (See Fig. 23)

c.

Two--Stage Thermostat and Two--Speed Cooling

See Fig. 26 for thermostat connections

NOTE

: The air conditioning relay disable jumper ACRDJ must

be disconnected to allow thermostat control of the outdoor unit

staging. (See Fig. 23)

The thermostat closes the R--to--G--and--Y1 circuits for

low--cooling or closes the R--to--G--and--Y1--and--Y2 circuits for

high--cooling. The R--to--Y1 circuit starts the outdoor unit on

low--cooling speed, and the R--to--G--and--Y1 circuit starts the

furnace blower motor BLWM at low--cooling airflow which is the

true on--board CF (continuous fan) selection as shown in Fig. 42.

The R--to--Y1--and--Y2 circuits start the outdoor unit on

high--cooling speed, and the R--to-- G--and--Y/Y2 circuits start the

furnace blower motor BLWM at high--cooling airflow.

High--cooling airflow is based on the A/C (air conditioning)

selection shown in Fig. 42.

The electronic air cleaner terminal EAC--1 is energized with 115

vac whenever the blower motor BLWM is operating.

When the thermostat is satisfied, the R--to--G--and--Y1 or R--to--

G--and--Y1--and--Y2 circuits are opened. The outdoor unit stops,

and the furnace blower BLWM and electronic air cleaner terminal

EAC--1 will remain energized for an additional 90 seconds.

Jumper Y1 to DHUM to reduce the cooling off--delay to 5

seconds. (See Fig. 23)

3.

Thermidistat Mode

See Fig. 25--27 for thermostat connections.

The dehumidification output, DHUM on the Thermidistat

should be connected to the furnace control thermostat ter-

minal DHUM. When there is a dehumidify demand, the

DHUM input is activated, which means 24 vac signal is

removed from the DHUM input terminal. In other words,

the DHUM input logic is reversed. The DHUM input is

turned ON when no dehumidify demand exists. Once 24

vac is detected by the furnace control on the DHUM input,

the furnace control operates in Thermidistat mode. If the

DHUM input is low for more than 48 hours, the furnace

control reverts back to non--Thermidistat mode.

The cooling operation described in item 2. above also ap-

plies to operation with a Thermidistat. The exceptions are

listed below:

a.

Low cooling

--When the R--to--G--and--Y1 circuit is

closed and there is a demand for dehumidification, the

furnace blower motor BLWM will drop the blower

airflow to 86 percent of cooling airflow which is the

true on--board CF (continuous fan) selection as shown

in Fig. 42.

b.

High cooling

--When the R--to--G--and Y/Y2 circuit is

closed and there is a demand for dehumidification, the

furnace blower motor BLWM will drop the blower

airflow to 86 percent of cooling airflow. Cooling air-

flow is based on the A/C (air conditioning) selection

shown in Fig. 42.

c.

Cooling off--delay

--When the “call for cooling” is

satisfied and there is a demand for dehumidification,

the cooling blower--off delay is decreased from 90

seconds to 5 seconds.

4.

Super--Dehumidify Mode

Super--Dehumidify mode can only be entered if the fur-

nace control is in the Thermidistat mode and there is a de-

mand for dehumidification. The cooling operation de-

scribed in item 3. above also applies to operation with a

Thermidistat. The exceptions are listed below:

a. When the R--to--Y1 circuit is closed, R--to--G circuit is

open, and there is a demand for dehumidification, the

Содержание 830CA

Страница 22: ...22 A180242 Fig 31 Chimney Inspection Chart...

Страница 26: ...26 Table 10 Furnace Setup Switch Description A190351...

Страница 27: ...27 A190348 Fig 38 Service Label...

Страница 43: ...43 A190249 Fig 45 Wiring Diagram...