11

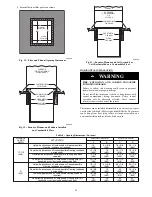

Suspended Furnace Support

The furnace may be supported under each end with threaded rod,

angle iron or metal plumber’s strap as shown. (See Fig. 15 and

16) Secure angle iron to bottom of furnace as shown.

Heavy--gauge sheet metal straps (plumber’s straps) may be used

to suspend the furnace from each bottom corner. To prevent

screws from pulling out, use 2 #8 x 3/4--in. (19 mm) screws into

the side and 2 #8 x 3/4--in. (19 mm) screws in the bottom of the

furnace casing for each strap. (See Fig. 15 and 16) If the screws

are attached to ONLY the furnace sides and not the bottom, the

straps must be vertical against the furnace sides and not pull away

from the furnace sides, so that the strap attachment screws are not

in tension (are loaded in shear) for reliable support.

Platform Furnace Support

Construct working platform at location where all required furnace

clearances are met. (See Fig. 2 and 17) For furnaces with 1--in.

(25 mm) clearance requirement on side, set furnace on

noncombustible blocks, bricks or angle iron. For crawl space

installations, if the furnace is not suspended from the floor joists,

the ground underneath furnace must be level and the furnace set

on blocks or bricks.

Roll--Out Protection

Provide a minimum 17--3/4 in. x 22 in. (451 mm x 559 mm)

piece of sheet metal for flame roll--out protection in front of

burner area for furnaces closer than 12 inches (305 mm) above

the combustible deck or suspended furnaces closer than 12 inches

(305 mm) to joists. The sheet metal MUST extend underneath the

furnace casing by 1 in. (25 mm) with the door removed.

The bottom closure panel on furnaces of widths 17--1/2 in. (445

mm) and larger may be used for flame roll--out protection when

bottom of furnace is used for return air connection. See Fig. 17

for proper orientation of roll--out shield.

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed in

bottom return--air opening. Remove and discard this panel when

bottom return air is used. To remove bottom closure panel,

perform the following:

1. Tilt or raise furnace and remove two screws holding bot-

tom filler panel. (See Fig. 9)

2. Rotate bottom filler panel downward to release holding

tabs.

3. Remove bottom closure panel.

4. Reinstall bottom filler panel and screws. Side Return Air

Inlet

Side Return Air Inlet

These furnaces are shipped with bottom closure panel installed in

bottom return--air opening. This panel MUST be in place when

side return air inlet(s) is used without a bottom return air inlet.

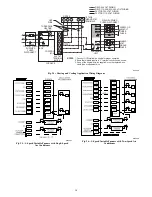

FILTER ARRANGEMENT

CARBON MONOXIDE AND POISONING

HAZARD

Failure to follow this warning could result in personal

injury, or death.

Never operate a furnace without a filter or with filter access

door removed.

!

WARNING

There are no provisions for an internal filter rack in these

furnaces.

A field--supplied accessory external filter is required.

Refer to the instructions supplied with the external filter rack for

assembly and installation options.

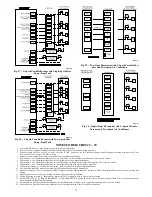

AIR DUCTS

General Requirements

The duct system should be designed and sized according to

accepted national standards such as those published by: Air

Conditioning Contractors Association (ACCA), Sheet Metal and

Air Conditioning Contractors National Association (SMACNA)

or American Society of Heating, Refrigerating and Air

Conditioning Engineers (ASHRAE) or consult The Air Systems

Design Guidelines reference tables available from your local

distributor. The duct system should be sized to handle the

required system design CFM at the design external static pressure.

The furnace airflow rates are provided in Table 11 -- AIR

DELIVERY--CFM (with filter).

When a furnace is installed so that the supply ducts carry air

circulated by the furnace to areas outside the space containing the

furnace, the return air shall also be handled by duct(s) sealed to

the furnace casing and terminating outside the space containing

the furnace.

Secure ductwork with proper fasteners for type of ductwork used.

Seal supply-- and return--duct connections to furnace with code

approved tape or duct sealer.

NOTE

: Flexible connections should be used between ductwork

and furnace to prevent transmission of vibration. Ductwork

passing through unconditioned space should be insulated and

sealed to enhance system performance. When air conditioning is

used, a vapor barrier is recommended.

Maintain a 1--in. (25 mm) clearance from combustible materials

to supply air ductwork for a distance of 36 in. (914 mm)

horizontally from the furnace. See NFPA 90B or local code for

further requirements.

Ductwork Acoustical Treatment

NOTE

: Metal duct systems that do not have a 90 degree elbow

and 10 ft. (3 M) of main duct to the first branch take--off may

require internal acoustical lining. As an alternative, fibrous

ductwork may be used if constructed and installed in accordance

with the latest edition of SMACNA construction standard on

fibrous glass ducts. Both acoustical lining and fibrous ductwork

shall comply with NFPA 90B as tested by UL Standard 181 for

Class 1 Rigid air ducts.

Supply Air Connections

For a furnace not equipped with a cooling coil, the outlet duct

shall be provided with a removable access panel. This opening

shall be accessible when the furnace is installed and shall be of

such a size that the heat exchanger can be viewed for possible

openings using light assistance or a probe can be inserted for

sampling the airstream. The cover attachment shall prevent leaks.

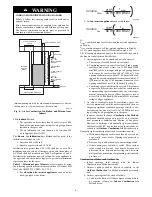

Upflow and Horizontal Furnaces

Connect supply--air duct to flanges on furnace supply--air outlet.

Bend flange upward to 90

_

with wide duct pliers. (See Fig. 14)

The supply--air duct must be connected to ONLY the furnace

supply--outlet--air duct flanges or air conditioning coil casing

(when used). DO NOT cut main furnace casing side to attach

supply air duct, humidifier, or other accessories. All accessories

MUST be connected to duct external to furnace main casing.

NOTE

: For horizontal applications, the top--most flange may be

bent past 90 degrees to allow the evaporator coil to hang on the

Содержание 830CA

Страница 22: ...22 A180242 Fig 31 Chimney Inspection Chart...

Страница 26: ...26 Table 10 Furnace Setup Switch Description A190351...

Страница 27: ...27 A190348 Fig 38 Service Label...

Страница 43: ...43 A190249 Fig 45 Wiring Diagram...