15

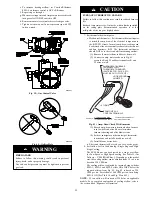

If pressure exceeds 0.5 psig (14--In. W.C.), gas supply pipe must

be disconnected from furnace and capped before and during

supply pipe pressure test. If test pressure is equal to or less than

0.5 psig (14--In. W.C.), turn off electric shutoff switch located on

furnace gas control valve and accessible manual equipment

shutoff valve before and during supply pipe pressure test. After

all connections have been made, purge lines and check for

leakage at furnace prior to operating furnace.

The gas supply pressure shall be within the maximum and

minimum inlet supply pressures marked on the rating plate with

the furnace burners ON and OFF.

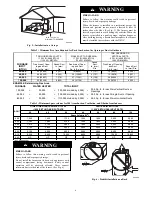

UNION

SEDIMENT

TRAP

MANUAL

SHUTOFF

VALVE

(REQUIRED)

GAS

SUPPLY

A02035

Fig. 21 -- Typical Gas Pipe Arrangement

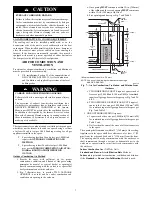

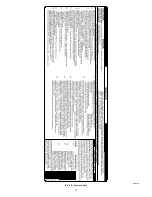

Table 5 – Maximum Capacity of Pipe*

NOMINAL IRON PIPE

INTERNAL DIAMETER

LENGTH OF PIPE --- FT. (M)

SIZE IN. (mm)

In. (mm)

10

20

30

40

50

1/2 (13)

0.622 (16)

175 (53)

120 (37)

97 (30)

82 (25)

73 (22)

3/4 (19)

0.824 (21)

360 (110)

250 (76)

200 (61)

170 (52)

151 (46)

1 (25)

1.049 (27)

680 (207)

465 (142)

375 (114)

320 (98)

285 (87)

1---1/4 (32)

1.380 (35)

1400 (427)

950 (290)

770 (235)

660 (201)

580 (177)

1---1/2 (38)

1.610 (41)

2100 (640)

1460 (445)

1180 (360)

990 (301)

900 (274)

* Cubic ft. of natural gas per hr for gas pressures of 0.5 psig (14---In. W.C.) or less and a pressure drop of 0.5---In. W.C. (based on a 0.60 specific gravity

gas). Ref: Chapter 6 current edition of ANSI Z223/NFPA 54.

Table 6 – Electrical Data

Unit Size

Volts-

Hertz-

Phase

Operating Voltage*

Range

Maximum

Unit Amps

Unit

Ampacity#

Minimum

Wire Size

AWG

Maximum

Wire

Length‡ ft

Maximum

Fuse or

CKT BKR†

Amps

Maximum

Minimum

036040

115-60-1

127

104

11.4

12.6

14

29

15

048060

115-60-1

127

104

11.4

12.6

14

29

15

060080

115-60-1

127

104

17.8

18.9

12

30

20

060100

115-60-1

127

104

17.8

18.9

12

30

20

* Permissible limits of the voltage range at which the unit operates satisfactorily.

# Unit ampacity = 125 percent of largest operating component’s full load amps plus 100 percent of all other potential operating components’ (EAC, humidifier,

etc.) full load amps.

{

Time---delay type is recommended.

}

Length shown is as measured one way along wire path between unit and service panel for maximum 2 percent voltage drop.

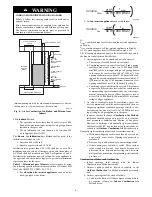

ELECTRICAL CONNECTIONS

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow safety warnings could result in dangerous

operation, serious injury, death or property damage.

Improper servicing could result in dangerous operation,

serious injury, death or property damage.

-- Before servicing, disconnect all electrical power to

furnace.

-- When servicing controls, label all wires prior to

disconnecting. Reconnect wires correctly.

-- Verify proper operation after servicing.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death

.

Blower access panel door switch opens 115--v power to

control. No component operation can occur. Do not bypass

or close switch with panel removed.

!

WARNING

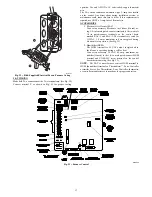

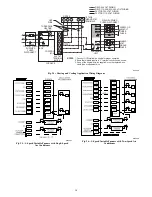

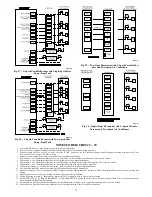

See Fig. 24 for field wiring diagram showing typical field 115--v

wiring. Check all factory and field electrical connections for

tightness.

Field--supplied wiring shall conform with the limitations of 63

_

F

(35

_

C) rise.

Содержание 830CA

Страница 22: ...22 A180242 Fig 31 Chimney Inspection Chart...

Страница 26: ...26 Table 10 Furnace Setup Switch Description A190351...

Страница 27: ...27 A190348 Fig 38 Service Label...

Страница 43: ...43 A190249 Fig 45 Wiring Diagram...