28

2. Determine the correct outlet gas pressure adjustment.

a. Obtain average yearly gas heat value (at installed altitude)

from local gas supplier.

b. Obtain average yearly gas specific gravity from local gas

supplier.

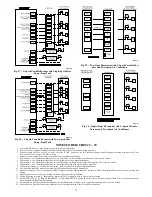

c. Find closest natural gas heat value and specific gravity

in Tables 15 through 17.

d. Follow heat value and specific gravity lines to point of

intersection to find outlet pressure setting for proper

operation.

3. Check Inlet Gas Pressure

The inlet gas pressure must be checked with the furnace

operating. This is necessary to make sure the inlet gas pressure

does not fall below the minimum pressure of 4.5 in. w.c.

a. Make sure the gas supply is turned off to the furnace and

at the electric switch on the gas valve

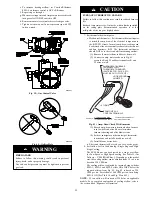

b. Loosen set screw on outlet tower pressure tap no more

than one full turn with a 3/32

−

in. hex wrench or remove

the 1/8

−

in. NPT plug from the inlet pressure tap on the

gas valve.

c. Connect a manometer to the inlet pressure tap on gas

valve.

d. Turn on furnace power supply.

e. Turn gas supply manual shutoff valve to ON position.

f. Turn furnace gas valve switch to ON position.

g. Jumper R and W thermostat connections at the furnace

control board.

h. When main burners ignite, confirm inlet gas pressure is

between 4.5 in. W.C. (1125 Pa) and 13.6 in. W.C. (3388

Pa).

i. Remove jumper across thermostat connections to

terminate call for heat. Wait until the blower off delay is

completed.

j. Turn furnace gas valve electric switch to OFF position.

k. Turn gas supply manual shutoff valve to OFF position.

l. Turn off furnace power supply.

m. Remove manometer from the inlet pressure tap of the gas

valve.

n. Tighten set screw on inlet tower pressure tap with

3/32

−

in. hex wrench, or if 1/8

−

in. NPT plug was

removed, apply pipe dope sparingly to end of plug and

re

−

install in the gas valve

FIRE HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Inlet pressure tap set screw must be tightened and 1/8--in.

NPT pipe plug must be installed to prevent gas leaks.

!

WARNING

4. Adjust gas valve outlet pressure determined in Step 2. to

obtain correct input rate.

a. Turn gas valve ON/OFF switch to OFF.

b. Loosen set screw on inlet tower pressure tap no more than

one full turn with a 3/32 in. hex wrench. (See Fig. 39)

c. Connect a water column manometer or similar device to

pressure tap on the gas valve.

d. Turn gas valve ON/OFF switch to ON.

e. Manually close blower door switch.

f. Set thermostat to call for heat.

g. Remove regulator seal cap and turn regulator adjusting

screw counterclockwise (out) to decrease input rate of

clockwise (in) to increase input rate.

h. Install regulator seal cap.

i. Leave manometer or similar device connected and pro-

ceed to next step.

NOTE

: If orifice hole appears damaged or it is suspected to have

been redrilled, check orifice hole with a numbered drill bit of

correct size. Never redrill an orifice. A burr--free and properly

sized orifice hole is essential for proper flame characteristics.

5. Verify natural gas input rate by clocking meter.

NOTE

: Gas valve regulator adjustment cap must be in place for

proper input to be clocked.

a. Turn off all other gas appliances and pilots served by the

meter.

b. Run furnace for 3 minutes in heating operation.

c. Measure time (in seconds) for gas meter to complete 1

revolution and note reading. The 2 or 5 cubic feet dial

provides a more accurate measurement of gas flow.

d. Refer to Table 13 for cubic ft. of gas per hr.

e. Multiply gas rate (cu ft./hr) by heating value (Btuh/cu ft)

to obtain input.

If clocked rate does not match required input from Step 1,

increase gas valve outlet pressure to increase input or decrease gas

valve outlet pressure to decrease input. Repeat steps b through e

until correct input is achieved. Reinstall regulator seal cap on gas

valve.

6. Set temperature rise. The furnace must operate within the

temperature rise ranges specified on the furnace rating

plate. Do not exceed temperature rise range specified on

unit rating plate. Determine the temperature rise as

follows:

NOTE

: Blower access door must be installed when taking

temperature rise reading. Leaving blower access door off will

result in incorrect temperature measurements. When setup switch

SW1--4 is ON, operation will be near the high end of the rise

range for improved comfort. Furnace must operate within the

temperature rise range specified on the furnace rating plate.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Disconnect 115--v electrical power and install lockout tag

before changing speed tap.

!

WARNING

a. Place thermometers in return and supply ducts as close

to furnace as possible. Be sure thermometers do not see

radiant heat from heat exchangers. Radiant heat affects

temperature rise readings. This practice is particularly im-

portant with straight--run ducts.

b. When thermometer readings stabilize, subtract return--air

temperature from supply--air temperature to determine air

temperature rise.

NOTE

: If the temperature rise is outside this range, first check:

(1.) Gas input for heating operation.

(2.) Return and supply ducts for excessive restrictions

causing static pressures greater than the maximum

heating static listed on the rating plate.

(3.) Ensure Comfort/Efficiency SW1--4 on furnace con-

trol is in OFF = Efficiency position when a bypass

humidifier is used (See Table 10).

(4.) Make sure proper model plug is installed.

c. Adjust air temperature rise by adjusting blower speed.

Increase blower speed to reduce temperature rise.

Decrease blower speed to increase temperature rise.

d. Turn thermostat down below room temperature and

remove blower access door.

Содержание 830CA

Страница 22: ...22 A180242 Fig 31 Chimney Inspection Chart...

Страница 26: ...26 Table 10 Furnace Setup Switch Description A190351...

Страница 27: ...27 A190348 Fig 38 Service Label...

Страница 43: ...43 A190249 Fig 45 Wiring Diagram...