84

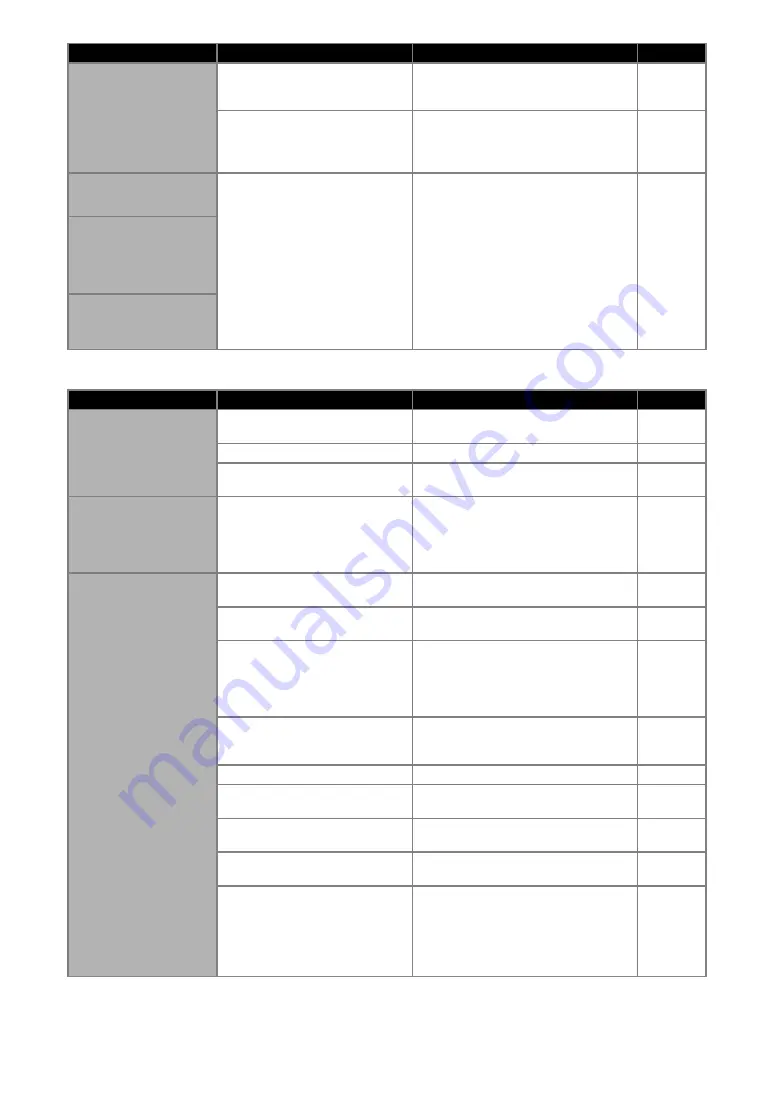

Cutting

The mat or the material

catches on a feed roller

when the mat is being

inserted.

The mat’s adhesive strength has

decreased, or the material is not

secured.

Press the “Feed” button to feed out the

mat, and then replace the mat with a new

one.

The material extends from the

adhesive area of the mat.

Press the “Feed” button to feed out the

mat, and then attach the material while

keeping it within the adhesive area of the

mat.

The mat or the material

catches on a feed roller

during cutting/drawing.

- The mat’s adhesive strength has

decreased, or the material is not

secured.

- The material extends from the

adhesive area of the mat.

Press the “Start/Stop” button to stop the

operation. Follow the instructions on the

screen, and press the “Feed” button to

feed out the mat.

If the mat does not feed out, turn off the

machine, remove the holder, and then

manually feed out the mat.

After feeding out the mat, replace it with a

new one or attach the material while

keeping it within the adhesive area of the

mat.

The mat is fed in at an

angle and is not fed

during cutting/drawing.

The material to be cut/

drawn or original to be

scanned peels off during

cutting/scanning.

Symptom

Possible Causes (or Results)

Solutions

Reference

The material being cut

catches on the tip of the

cutting blade.

Dust or lint has accumulated in the

holder.

Clean the holder.

The blade is worn.

Replace the blade with a new one.

The material being cut is

incompatible with this machine.

Replace the material with one compatible

with this machine.

The machine stopped

while an operation is

being performed.

For safety, the machine stops

operating if the panel is touched

while cutting or drawing.

Follow the instructions in the message

that appears in the screen. Touch the

“OK” key to move the carriage to its initial

position. Load the mat and perform the

operation again.

—

Not all of the material to

be cut is cut. Some

areas remain uncut.

A blade appropriate for the material

being cut is not used.

Use a blade appropriate for the material

being cut.

The blade extension from the blade

holder is too little.

Remove the holder from the carriage, and

then adjust the blade extension.

If cutting is not possible even though

the blade extension or cutting

pressure is set higher than

necessary, the blade may be

chipped.

Replace the blade with a new one.

The mat’s adhesive strength has

decreased, or the material is not

secured.

Replace the mat with a new one.

The blade is worn.

Replace the blade with a new one.

The material is incompatible with

this machine.

Replace the material with one compatible

with this machine.

The cutting pressure (“Cut

Pressure”) is incorrect.

Adjust the setting for “Cut Pressure” in the

settings screen.

Dust or lint has accumulated in the

holder.

Clean the holder.

The spacing between arranged

patterns is too small.

Rearrange the patterns to slightly separate

them.

Set the number to “3” or higher in the

“Pattern Interval” setting, and then

rearrange the patterns or perform the auto

layout function.

Symptom

Possible Causes (or Results)

Solutions

Reference