ACS 561 Service Manual

Robert Bosch GmbH

SP00D00517

2018-07-11

62

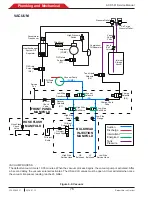

Plumbing and Mechanical

Plumbing and Mechanical System

Operation

The plumbing and mechanical system is con-

trolled by electrical impulses from the electrical

system. There are five main components to the

plumbing system:

• Compressor

• Vacuum Pump

• Panel Manifold Assembly

• Internal Storage Vessel (ISV)

Along with these components are several ancil-

lary components:

• Cooling Fan

• Bulkhead Oil Inject Assembly

• Oil Drain Bottle

• High and Low Side Gauges

• High (red) and Low (blue) Side Service

Hoses

All components are interconnected with vari-

ous lengths and diameters of flexible tubing or

copper tubing. The copper tubing is to connect

the compressor discharge port to the manifold

assembly. All lines connected to the compressor

are high pressure lines.

Compressor

The compressor is configured for R1234yf

refrigerant. When replacing the compressor,

heed the warnings, cautions, and any other

related safety information. For compressor

specifications, see

General Information

.

Vacuum Pump

The vacuum pump is used in this unit for the

recovery and vacuum processes. For vacuum

pump specifications, see

General Information

.

Manifold Assembly

The “top” or “panel” manifold assemblly consists

of the high- and low-side pressure gauges,

high- and low-side manually operated ball

valves, and three solenoids (S1, Recover; S2,

Vacuum; and S3, Charge). This unified as-

sembly permits efficient, reliable, operation of

the unit.

Unlike other units, this assembly does not have

the oil separator and filter/dryer attached to

it.This manifold assembly is not interchange-

able with any other manifold assemblies. Repair

or replacement of the manifold should be per-

formed under clean conditions so particulates

do not enter the assembly from any open ports.

Particulates can clog the small chambers and

cause solenoid and check valve malfunctions,

as well as contaminate a vehicle air condition-

ing system.

Internal Storage Vessel (ISV)

The ISV stores the refrigerant from the vehicle

A/C system and from the external refrigerant

source tank. It is important to note that if the

external source tank is always connected to the

unit, the unit will make sure the required amount

of refrigerant is always in the ISV through the

“Tank Fill” function which will run in the back-

ground whenever the unit is in use.

Ancillary components and assemblies included

are:

Cooling Fan:

The cooling fan is necessary to

keep the compressor below its maximum am-

bient operation temperature of 50°C (140°F)

or less. The fan is also used to prevent build

up of refrigerant in the cabinet and prevent

fire. Attached to the cooling fan is a small fan

which is used as an airflow sensor. If the cool-

ing fan is not operating, the airflow sensor will

not turn, and thus a signal will not be sent to

the control board. When this happens, the unit

will not operate.

Bulkhead Oil Inject Block Assembly:

This

assembly serves as the attachment ports for

the high- and low-side service hoses and as

the oil injection point through the Oil Inject

Solenoid (S5).

Содержание ACS 561

Страница 1: ...ACS 561 en Repair instruction A C Service Unit ...

Страница 95: ......