37

DuraSweeper

®

Standard Operation

This will describe a typical operation.

Warnings

• Operation of the DuraSweeper

®

should not be initiated without reading and understanding the

information below.

• Flying Debris Hazard! Vehicle operators should remain in vehicle and close all doors and windows

while passing under the DuraSweeper

®

. Adequate space to the side should be available to

accommodate the significant volumes of removed material.

• Ensure operator’s area is free of debris.

• Insure that all the instruction and safety labels are in place and readable.

• Read and follow all safety labels.

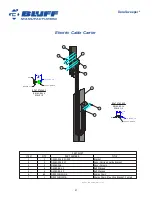

1. Turn the key switch to AUTO.

2. The truck driver will pull through making sure they are centered between the base frames of the

DuraSweeper

®

. The driver is to pull up until they are sure the truck is positioned so the brush will

come down and contact the desired horizontal surface.

3. Once positioned correctly, the driver will push the Activation Bar, which will start the brush rotating

and initiate the lowering of the Brush Carriage Assembly.

4. After the Brush contacts the truck, the driver should pull forward very slowly. The Brush will

automatically maintain proper contact with the truck. The brush will rise if the driver moves forward

to quickly, or the truck roof height gets taller toward the back, or if there are any structures on the top

surface of the truck.

5. After the truck is finished being swept, the driver moves on, and the DuraSweeper

®

will move down

3 to 4 feet, and then return back to the top, ready for another truck. If another truck doesn’t arrive, the

brush motor will turn off after 5 minutes.

6. Whether the brush is spinning or not, the unit is ready for another truck. When the next truck is in

position, the operator needs to push the activation to initialize another sweep cycle.

The unit is ready for service at any time, whether the brush has stopped spinning or not.