11

ENGLISH

3 Outdoor sensor temperature

°C

-20..70

4 Burner output

%

0..100

5 Not signi

fi

cant

KOhm

0..99

6 Fan speed

--

0..3

0 = Off, 1 = Min, 2 = Med,

3 = Max

7

Interval remaining before mainte-

nance

--

52

weeks

To exit the Info menu press RESET for 1 second, or press RESET for 10 seconds to exit

con

fi

guration mode.

b

By pressing the DHW+ and DHW- buttons simultaneously, it is possible to reset the

remaining service interval.

4.13

Alarms

log

Access the alarm log menu as follows:

-

press the RESET button for 10 seconds to enter the con

fi

guration mode. "tS" starts

fl

ashing on the display

-

press CH+ or CH- buttons to navigate the menu, select the Alarm log menu (Hi) and

press MODE to enter it.

The electronic board records the last 11 error codes from the most recent to the oldest.

b

Access to the menu is not allowed with the boiler in the OF state.

Par. Note

Description

r01

most recent error

r02

r03

r04

r05

r06

r07

r08

r09

r10

r11

oldest error

Press CH+ or CH- buttons to select the error, which is shown on the display with the letter

"A", alternating every 2 sec. with the numerical index of the alarm log (e.g. r01).

Press the RESET button for 1 second to exit alarm log mode or press the RESET button for

10 seconds to exit the con

fi

guration mode.

Reset alarm log

In con

fi

guration mode, press the CH+ or CH- button to navigate the menu and select the

Reset Alarm Log menu (rE).

While the display shows "rE", by pressing the MODE button for 3 seconds, it is possible to

reset the whole alarm history. After resetting the history information, the system automatically

exits installation mode.

4.14

Combustion

analysis

To activate the combustion analysis function:

-

remove the casing by undoing the fastening screws

-

undo the

fi

xing screw of the instrument panel and rotate it to a horizontal position

-

remove the screw (

A

-

fi

g. 13) and the

fl

ue gas analysis take-off plug (

B

-

fi

g. 13) and

insert the analyser

-

loosen the screw of the pressure test take-off downstream from the gas valve by roughly

two turns, then connect the pressure gauge

-

reposition the control panel and

fi

x it in place with the screw

-

place the boiler in winter mode

-

press the RESET and MODE buttons simultaneously for 5 seconds

-

the boiler will switch on at max. power; the display will show the value 100 and the

symbols will be

fl

ashing

-

read the CO and CO

2

values on the

fl

ue gas analyser. If they are different from the

values in the multigas table, check the gas pressure on the pressure gauge; if they are

correct, quit the procedure by pressing the RESET and MODE buttons simultaneously

for 5 seconds

-

if the gas pressure values read on the gauge differ from the multigas table indications,

make the adjustment by following the procedure explained in paragraph "4.16.2 Limited

range adjustment" , if on the other hand they are correct, it means the problem is not related

to the gas valve adjustment and must instead be located on the combustion components.

The combustion control function is automatically disabled after 15 minutes, or by pressing

RESET and MODE for 5 sec.

In the case of a zone system or heat dispersal in the heating system, the procedure can be

followed in DHW mode by turning on at least one hot water tap after activating the function

as explained previously, making sure that the DHW setpoint is set to the maximum value.

Remember to set it to the user desired value when

fi

nished the sequence.

When the checks have been carried out:

-

remove the pressure gauge

-

remove the

fl

ue gas analyser, close the pressure point, replace the

fl

ue gas analysis

socket cap and reposition the previously removed components.

4.15 Gas

convertion

The transformation from a gas of one family to a gas of another family can be easily done

even with the boiler installed.

The boiler is supplied for natural gas (G20) or LPG (G31) as indicated on the product plate.

- Empty the system completely, disconnect the power supply and close the gas tap.

- Access the internal parts of the boiler.

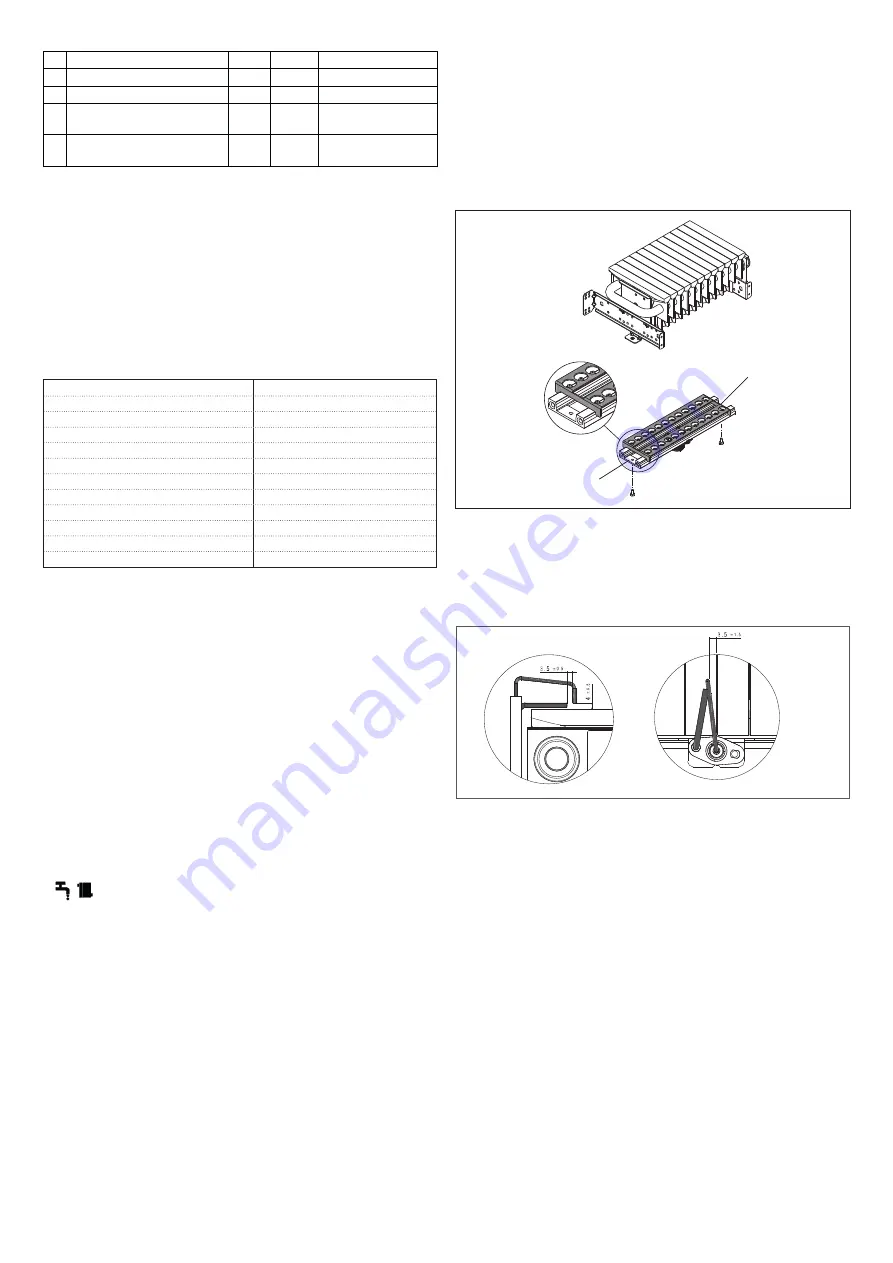

- Extract the burner completely with the collector connected, being very careful not to

damage the gas train cable gland.

CONVERTION FROM NG TO LPG

- Disconnect the NG manifold from the burner by unscrewing the appropriate

fi

screws.

- Take the LPG manifold and the

fl

ange from the appropriate conversion kit and, using the

screws previously removed, fasten both to the burner.

CONVERTION FROM LPG TO NG

- Disconnect the LPG manifold from the burner by unscrewing the appropriate

fi

xing screws.

- Remove the LPG

fl

ange.

- Take the NG manifold from the appropriate conversion kit and, using the screws

previously removed, fasten both to the burner.

LPG

fl

ange

manifold

- Reposition the burner in its seat,

fi

xing the two support brackets with the 4 screws

previously removed to the bottom of the air box.

- Reposition the spark plug and the support bracket, with the relative screws.

- Reassemble carefully following the reverse procedure.

- Pay attention to the good condition of all seals and OR, making a general tightness

check.

- Reassemble the bracket with the spark plug, checking the correct position of the

electrode as shown in the

fi

gure.

- Set parameter P01 as follows:

P01= 0 NG

P01= 1 LPG.

- After the gas transformation operations, proceed with a calibration of the gas valve as

described in paragraph "4.16.1 Auto-setting".

b

The transformation must be carried out only by quali

fi

ed personnel.

b

At the end of the transformation, apply the new identi

fi

cation plate contained in the kit.

4.16 Adjustments

The boiler is supplied for operation with methane gas (G20) or LPG (G31) and is factory set

as shown on the data plate.

b

Adjustments must be made in the sequence indicated and exclusively by the

Technical Assistance Service.

b

Adjustments cannot be made if the boiler is in the OFF state.

-

Remove the casing by loosening the fastening screws.

-

Undo the

fi

xing screw of the instrument panel.

-

Loosen the screw of the pressure test point downstream from the gas valve by roughly

two turns, then connect the pressure gauge.

4.16.1

Auto-setting

THIS PROCEDURE SHOULD ONLY BE CARRIED OUT IN THE FOLLOWING CASES:

GAS VALVE REPLACEMENT, BOARD REPLACEMENT, GAS CONVERSION.

The gas valve does not provide for mechanical calibration: valve adjustments are therefore

carried out electronically through two parameters q02 and q01.

-

Place the boiler in winter mode.

-

Referring to paragraph "4.11 Parameter access procedure (tS)" set parameter

P19 = 1

,

then exit the procedure.