35

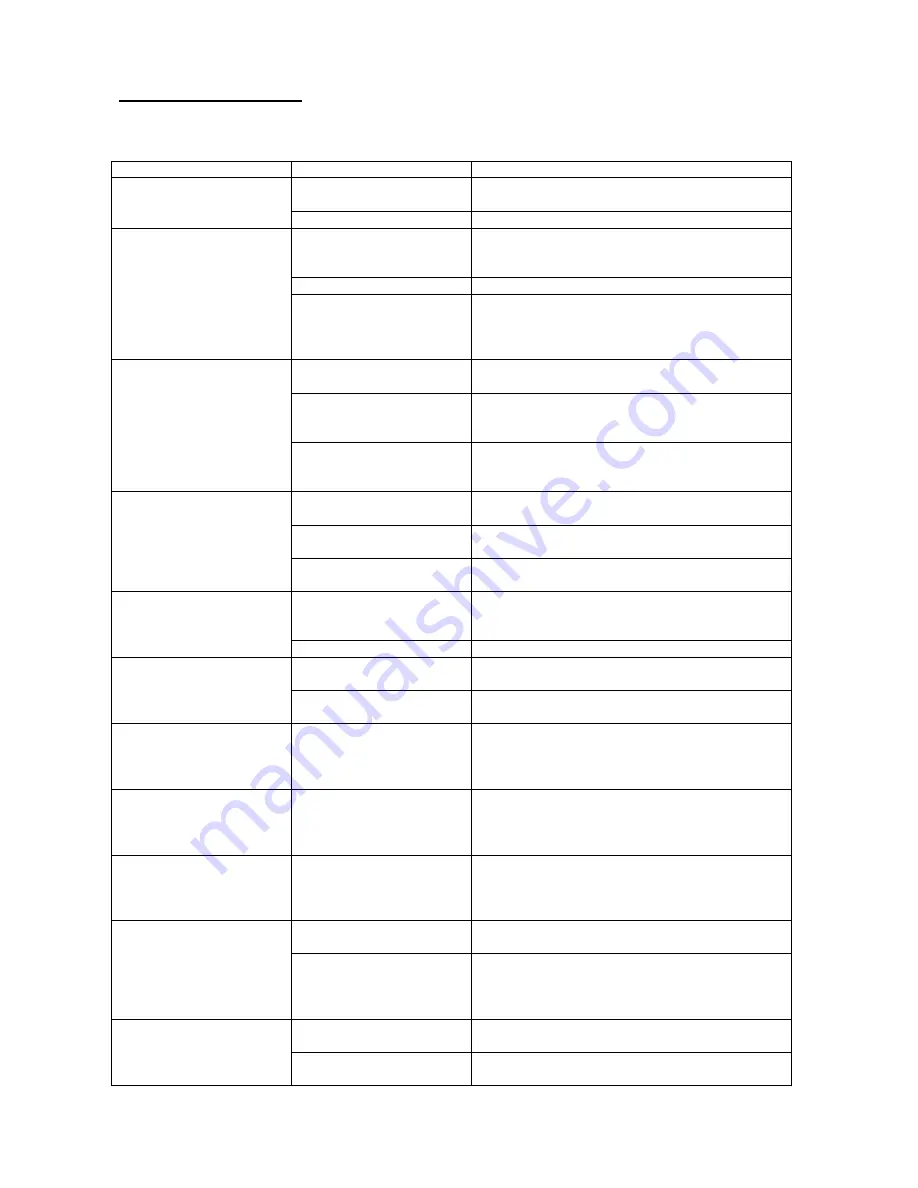

9. Troubleshooting

If you have problems with the operation of the boiler, try some of the following solutions:

SYMPTOM

CAUSE

SOLUTION

The boiler is not

connected to the mains.

Connect the boiler to the mains (400V/50Hz) via

power cord with plug.

The display does not

show any data.

Boiler controller failure.

Replace the boiler controller.*

Boiler drive cable Is

disconnected (or

damaged).

Connect (or replace) the boiler drive cable.*

Boiler drive is damaged.

Replace the boiler drive.*

Screw feeding device

does not work.

There was a motor

overheating and thus the

motor thermal protection

was activated.

Let the motor cool, after cooling the motor will

restart automatically.

The fuel feeder contains

an obstacle (stone, etc.).

Demount the fuel feed screw and remove the

obstruction. Reassemble the feeder.*

The fuel contains a

substantial quantity of

dust.

Remove unsuitable fuel from the boiler, refill the

container with prescribed fuel.

Repeated activation of the

motor thermal protection.

The alignment of the

drive, screw shaft and

burner is not correct.

Disassemble the fuel screw feeder, clean and

reassemble it with emphasis on ensuring the

alignment of the individual components.*

The container does not

contain fuel.

Refill the container with prescribed fuel.

Overall wear of the screw

shaft.

Replace the screw shaft.*

The screw shaft rotates,

though the fuel is not

transported into the

combustion chamber.

The turnstile chain was

damaged.

Replace the turnstile chain.*

Boiler fan cable is

disconnected (or

damaged).

Connect (or replace) the boiler fan cable.*

Boiler fan does not work.

The fan is damaged.

Replace the boiler fan.*

The fan was clogged by

dust.

Clean the boiler fan.*

The fan is noisy in

operation.

The fan bearings are

worn.

Replace the entire boiler fan.*

The fan does not rotate

during boiler modulation

at the lowest output

values.

The set values of the fan

speed are too low.

Increase the fan speed on the boiler controller

so as to guarantee its smooth operation.

Water from the

emergency fire-fighting

equipment leaked into the

fuel feeder.

The fuel burnt through to

the fuel feeder, which

activated the thermostatic

valve.

Remove wet fuel from the feeder, fill the

container with new dry fuel and start-up the

boiler.

Water from the

emergency fire-fighting

equipment leaks into the

fuel feeder.

The thermostatic valve on

the feeder leaks.

Replace the thermostatic valve.

The boiler is filled with wet

fuel.

Refill the container with dry fuel.

The walls of the fuel tank

are covered with droplets

of water.

The temperature in the

boiler room is low (about

12 °C or less)

The boiler room requires a higher air

temperature (boiler room wall insulation,

installation of heating radiator to the boiler room,

etc.).

A short time passed after

firing in the boiler.

Let the boiler thoroughly flame up.

The boiler cannot reach

the rated output during

operation.

Fuel dosing is set to a

lower output.

Adjust the fuel dosing according to the control

unit instruction manual.

Содержание S16

Страница 1: ...BOILER OPERATING AND INSTALLATION INSTRUCTION MANUAL BENEKOV S16 BENEKOV S26 BENEKOV S51 ...

Страница 20: ...20 Fig no 14 Boiler ash remover for S51 Fig no 15 Boiler flue gas exhaust for S16 and S26 ...

Страница 27: ...27 Fig no 22 Connection dimensions of BENEKOV S26 boiler ...

Страница 28: ...28 Fig no 23 Connection dimensions of BENEKOV S51 boiler ...