5 Startup

5.1 Design guidelines

28

OZD Profi G12D... ATEX 1 V. 03 07/2014

5.1.7 Execution of sheath connections

Kindly consider following points when laying the cable

sheaths:

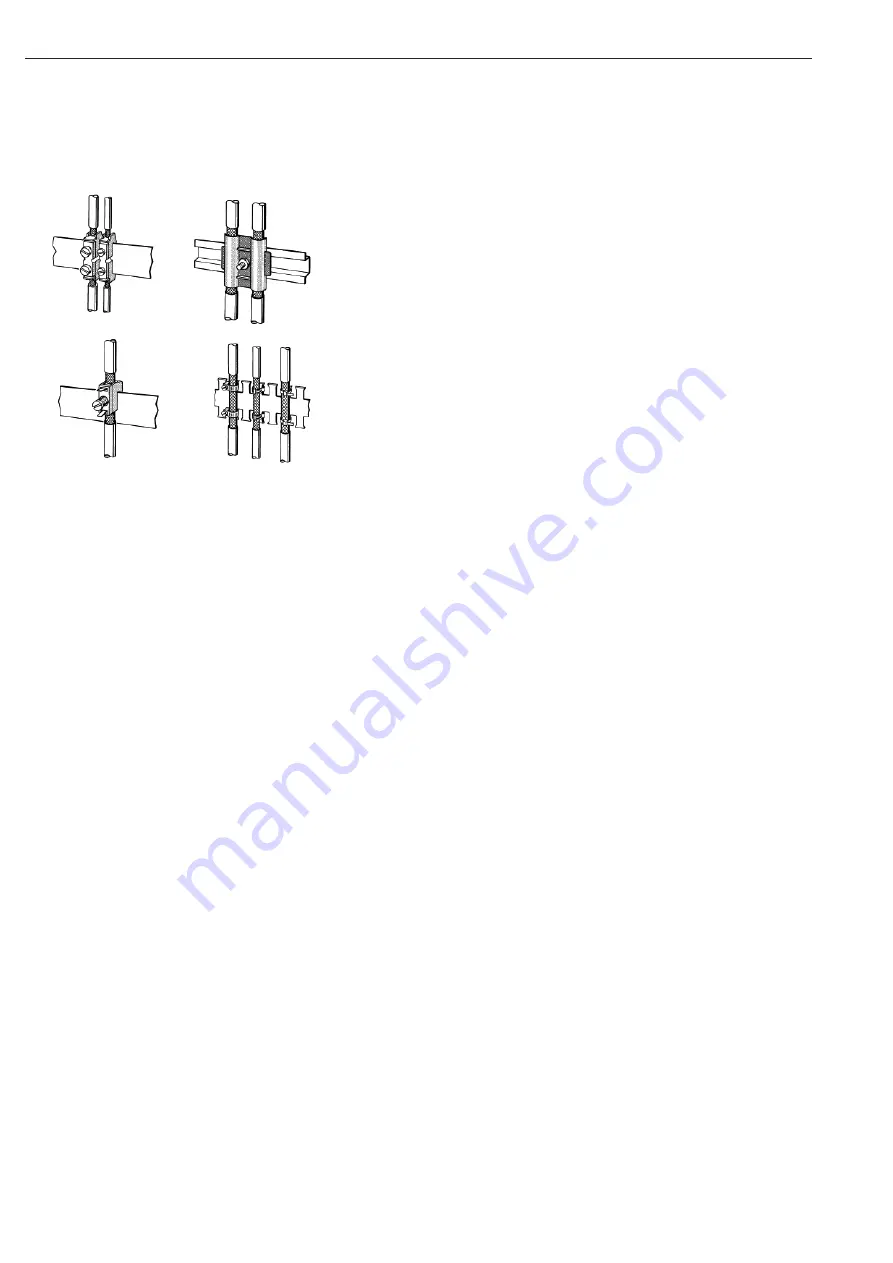

Fix braid cable sheath with metal cable clamps.

The clamps must extensively enclose the sheath and

have a good contact (see Figure 10).

Contact the cables only through the copper braid

sheath and not through the aluminium foil sheath. The

foil sheath is placed on a plastic foil for increasing the

tensile strength and thus non-conductive!

All cable sheaths leading from outside to the protecti-

ve housing must be intercepted at the entry point of

the protective housing and extensively contacted with

the earth of the protective housing.

When removing the cable sheaths ensure that the

braid sheath of the cables is not damaged. Tinned or

galvanically stabilised surfaces are ideal for a good

mutual contact of grounding elements. For tinned sur-

faces, the required contacts must be ensured with a

suitable gland. Painted surfaces at the point of

contact are not suitable.

Sheath catching/contacts must not be used as strain

relief. Contact to the shielding bus may deteriorate or

tear.

Fig. 10: Fixing sheathed cables with cable clamps and hose clip

(schematic presentation)