FLIPPING™ ARCH

1MANUL027

Belanger®, Inc. *PO BOX 5470 *Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

25

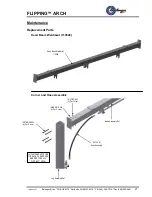

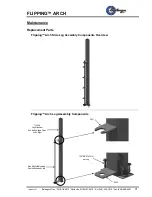

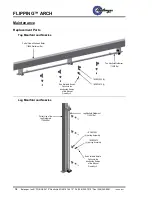

Maintenance

Routine Procedures

Flipping

™ Arch (Daily)

Clean and inspect the wash tunnel for debris.

Inspect all chemical levels. Replace as necessary.

Visually check the spray of each of the nozzles. Clean or replace as necessary.

Visually inspect all hoses and airlines for damage or wear. Replace as necessary.

Inspect the arch for clogged nozzles. This can best be done while running a test vehicle at

the start of the business day. Nozzles can be cleaned by inserting a thin wire into the nozzle

opening to clear any obstructions. Sometimes simply tapping on the nozzle can clear it.

Run a test wash

Flipping

™ Arch (Monthly)

Inspect all fasteners and anchors on the frame and any additional add-on components.

Inspect the air pressure on the air panel regulators. Adjust as necessary.

Wash component down with a good degrimer such as Tide laundry detergent and hot water.

Support Equipment

For any equipment NOT supplied by Belanger®, refer to the corresponding manual for any

maintenance procedures or additional recommended or needed activities.

Drain any water out of the ai

r compressor tank according to the manufacturer’s

recommendations.

For any equipment supplied by Belanger®, refer to the supplied Belanger® manuals.

Trouble Shooting

Problem

Cause

Solution

Pulsating or weak

spray

Nozzles clogged

Dirt in solenoid valve

Kink in hose

Inadequate water pressure

Remove from arch manifold and clean with thin wire

Disassemble and clean solenoid valve

Remove any kinks from hose

Open water valve to fullest

Note: Turn off main power before working on the machine!