Page

39

Section 9

Maintenance & Inspection

Dragonfly 582/912

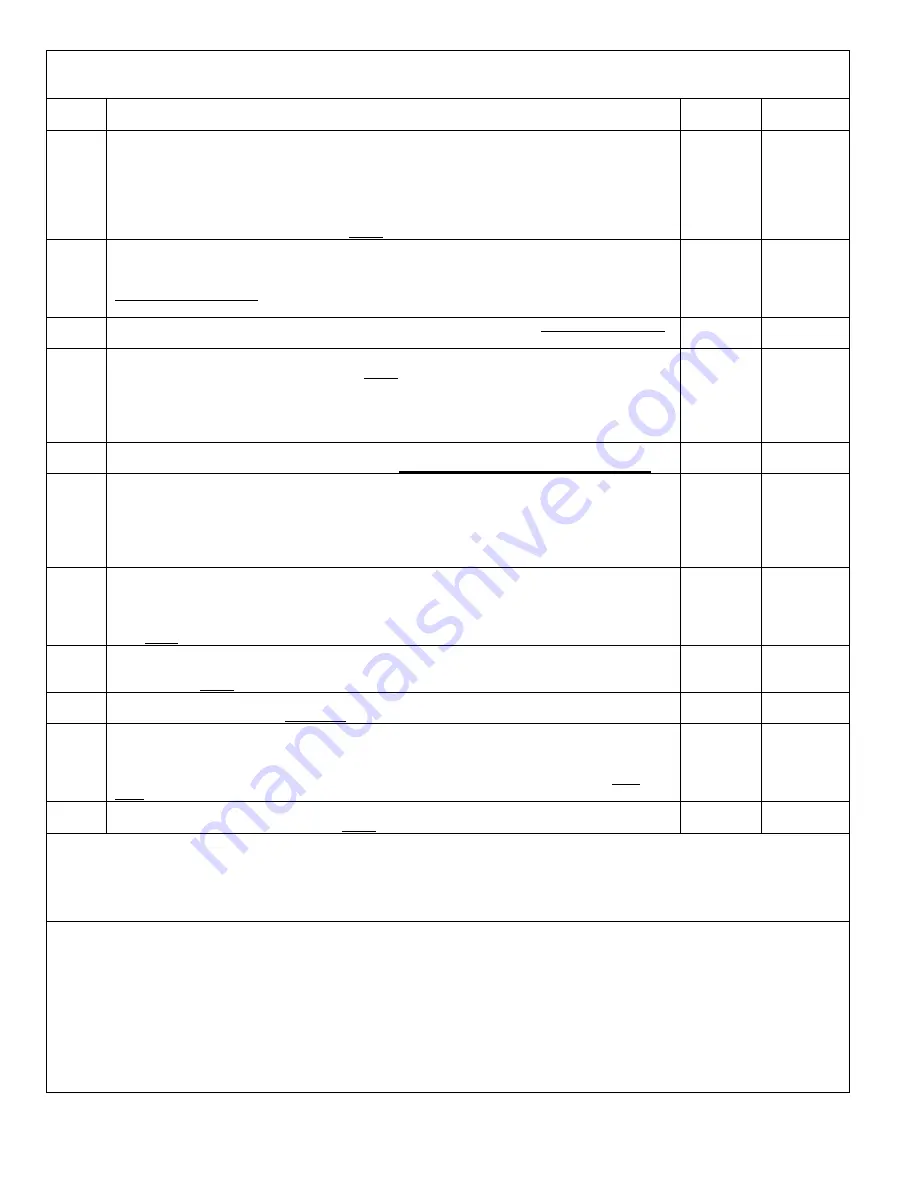

VERTICAL STABILIZER

STEP

INSTRUCTIONS for Assembly, for Disassembly reverse the order!

PART NO.

STAGE

CERT.

1

Wrap mylar shim around

vert stab fwd

and slide into boom tube. Align holes. AN4 half nut, 1/4" washer,

Bolt vert stab fwd 1/4” x 6.25”,

cable clamp 1/4”,

cable clamp 1/4”

spacer stand off .375”,

boom tube, vert. stab fwd, boom tube, spacer stand off .375”, cable clamp 1/4”, cable

clamp 1/4”, 1/4" washer, AN4 half nut.

Tight.

DFC 003

DFO 004

DFT 431

DFG 008

2

Shave half of one end of

1/2" tube inserts

at slight angle.

Pop rivet aluminium 3/16” x 5/8”,

1/2" angled tube insert, vert stab fwd. Align tube insert until approx. Parallel with boom tube.

Set rivet but do not pop.

If rivet is popped, plastic will expand and tube will not fit over it.

Squeeze rivet slightly until insert is tight against tube. Shank may be cut off with pliers.

DFP 017

DFT 413

3

Pop rivet aluminium 3/16” x 5/8”, angled 1/2" tube insert, vert stab aft.

Set rivet, do not pop.

See above.

4

Bolt AN3-13A, 3/16" washer, vert stab aft,

vert stab conn block,

vert stab aft, 3/16" washer, AN3 half nut.

Tight.

Slide fabric

vert stab

over vert stab aft through lower aft hole. Slide fabric over vert stab fwd through fwd lower

hole. Slide fabric halfway down and put

vert stab comp strut

in place. Slide fabric down as far as possible and work inside seams to one side. (If seam

flips, it will leave a bump).

DFP 037

DFR 015

DFF 011

5

100 hr

Bolt stainless hex head 1/4” x 20 TPI x 2 1/4",

1/4" washer, vert stab aft, vert stab conn block.

Tight: Inspect & tighten every 100 hrs.

DFT 001

6

Slide

vert stab tension tube

inside sail. (Tube is asymmetrical. Be sure correct end is in first). Burn elongated holes in

fabric at tension tube hole.

Bolt hex head 1/4” x 20 TPI x 6",

1/4" washer, main boom, vert stab fabric, vert stab tension tube. Tighten one bolt, then the

other to tighten fabric. (If DFT 005 bolt does not reach, threaded rod may be used).

*If you

intend to paint the sail, stop assembly of vert stab here and continue to next Section.

DFC 015

DFT 005

7

Burn holes in fabric for bolts

#

7, 8, 9, 11. Bolt AN3-26A, 3/16" washer,

horiz stab brkt,

spacer 1” x .25” x .125”,

saddle 1.75”,

vert stab aft, saddle 1.75”, spacer 1” x .25” x .125”,horiz stab brkt, 3/16" washer, AN3 half

nut.

Tight.

DFI 008

DFP 028

DFP 032

8

Bolt AN4-25AS**

, 3/16" washer, horiz stab brkt,

modified tube conn,

vert stab fwd, saddle 1”, modified tube conn saddle end 1”, horiz stab . brkt, 3/16" washer,

AN3 half nut.

Tight.

**(Switched from AN3-24A for Safety Dir. DF 1401)

DFP 042

9

Bolt AN3-20A,

hinge brkt,

vert stab aft, AN3 blind nut.

Very tight.

DFO 023

10

The hole that bolt

#

10 goes through is only partially drilled because of alignment. Using a

3/16" drill bit, insert into hole on one side of vert stab aft. Find hole on the other side and

drill. Bolt AN3-22A, hinge brkt, vert stab aft, 3/16" washer, AN3 half nut. Using short-

handled 3/16" wrench. (You can buy a cheap wrench and modify with hacksaw).

Very

tight.

11

Bolt AN3-20A,

tail-upper,

vert stab aft, tail-upper, AN3 half nut.

Tight.

DFR 002

(1)

Recommended Special Tools:

None

(2)

The parts needed to perform the task:

Replace worn/damaged parts as needed, listed above. Max. Wear (defined 1.1.8.1)

(3)

Type of maintenance:

Inspection=Line & Replacement=Heavy

(when it involves replacement of structural components.)

(4)

Certification needed to accomplish the task:

Line=LSRI Inspection or above, Heavy=LSRM Maintenance or above.

see:

3 Level of Certification in this manual

(5)

Detailed instructions and diagrams as needed to perform the task, listed above and adjacent page.

Every Annual or 100 Hrs., Inspect for Cracks, Corrosion, Elongation of holes & Fasteners for Wear & Security.

See: 1.3.5 Fabric Coverings: For more inspection and testing information on fabric coverings.

See

Cables, Thimbles and Tangs Page 16

(6)

Method to test/inspect to verify the task was accomplished properly.

Insure that all procedures were followed correctly and

there is proper non-binding movement to moving parts and that fasteners were tightened as instructed. When flight

controls are involved, assure that they are operating properly.

Section 9 Vertical Stabilizer

Section 9

Содержание 912 Dragonfly

Страница 3: ...Page 2 ...

Страница 4: ...Page 3 ...

Страница 5: ...Page 4 ...

Страница 25: ...Page 24 Drawing 1 ...

Страница 27: ...Page 26 Drawing 2 ...

Страница 29: ...Page 28 Drawing 3 ...

Страница 31: ...Page 30 Drawing 4 ...

Страница 33: ...Page 32 Drawing 5 ...

Страница 35: ...Page 34 Drawing 6 ...

Страница 37: ...Page 36 Note for Hydraulic Brakes see Appendix B Drawing 7 ...

Страница 39: ...Page 38 Drawing 8 ...

Страница 41: ...Page 40 Drawing 9 ...

Страница 43: ...Page 42 Drawing 10 ...

Страница 45: ...Page 44 Drawing 11 ...

Страница 47: ...Page 46 Drawings 12A 12B ...

Страница 49: ...Page 48 Drawing 13 ...

Страница 51: ...Page 50 Drawing 14 ...

Страница 53: ...Page 52 Drawing 15 ...

Страница 55: ...Page 54 Drawing 16 ...

Страница 57: ...Page 56 Drawing 17 ...

Страница 59: ...Page 58 Drawing 18 ...

Страница 61: ...Page 60 Drawing 19 ...

Страница 63: ...Page 62 Drawing 20 ...

Страница 65: ...Page 64 Drawing 21 ...

Страница 67: ...Page 66 Drawing 22 ...

Страница 69: ...Page 68 Drawing 23 ...

Страница 71: ...Page 70 Drawing 24 ...

Страница 73: ...Page 72 Drawing 25 ...

Страница 75: ...Page 74 Drawing 26 ...

Страница 77: ...Page 76 Drawing 27 ...

Страница 79: ...Page 78 Wiring1 jpg Drawing 28a ...

Страница 80: ...Page 79 Wiring2 jpg Drawing 28b ...

Страница 81: ...Page 80 elecLights jpg Drawing 28c ...

Страница 83: ...Page 82 Drawing 29 ...

Страница 85: ...Page 84 Drawing 30 ...

Страница 92: ...Page 91 Appendix B Brakes Manual for BX1320 BX1000 Appendix B Page 1 ...

Страница 93: ...Page 92 Appendix B Page 2 ...

Страница 94: ...Page 93 Appendix B Page 3 ...

Страница 96: ...Page 95 Appendix B Page 5 ...

Страница 97: ...Page 96 Appendix B Page 6 ...

Страница 98: ...Page 97 Appendix B Page 7 ...

Страница 104: ...Page 103 Figure 1a Description of Display Pages ...

Страница 105: ...Page 104 Figure 1b Description of Display Pages ...

Страница 138: ...Page 137 Appendix C EIS 4000 912 914 ...

Страница 139: ...Page 138 Appendix C EIS 4000 912 914 ...

Страница 140: ...Page 139 Appendix C EIS 4000 912 914 ...

Страница 141: ...Page 140 Appendix C EIS 4000 912 914 End Appendix C ...

Страница 155: ...Page 154 Appendix E2 Powerfin Prop Page 2 ...

Страница 156: ...Page 155 Appendix E2 Powerfin Prop Page 3 ...

Страница 157: ...Page 156 Appendix E2 Powerfin Prop Page 4 ...

Страница 158: ...Page 157 Appendix E2 Powerfin Prop Page 5 ...

Страница 159: ...Page 158 Appendix E2 Powerfin Prop Page 6 ...

Страница 160: ...Page 159 Appendix E2 Powerfin Prop Page 7 ...

Страница 161: ...Page 160 Appendix E2 Powerfin Prop Page 8 ...

Страница 162: ...Page 161 Appendix E2 Powerfin Prop Page 9 ...

Страница 163: ...Page 162 Appendix E2 Powerfin Prop Page 10 ...

Страница 164: ...Page 163 Appendix E2 Powerfin Prop Page 11 End of Appendix E2 ...

Страница 187: ...Page 186 By Memphis Soaring FIGURE 3 Common Signals ...