33

- Check the rim and the tyre, as described in the specific section of this manual.

- If the rim has been removed, clamp the wheel on the spindle flange, as described in

the WHEEL CLAMPING section.

NOTE: To ensure safety, you are recommended to use a specific tool to replace the

valve.

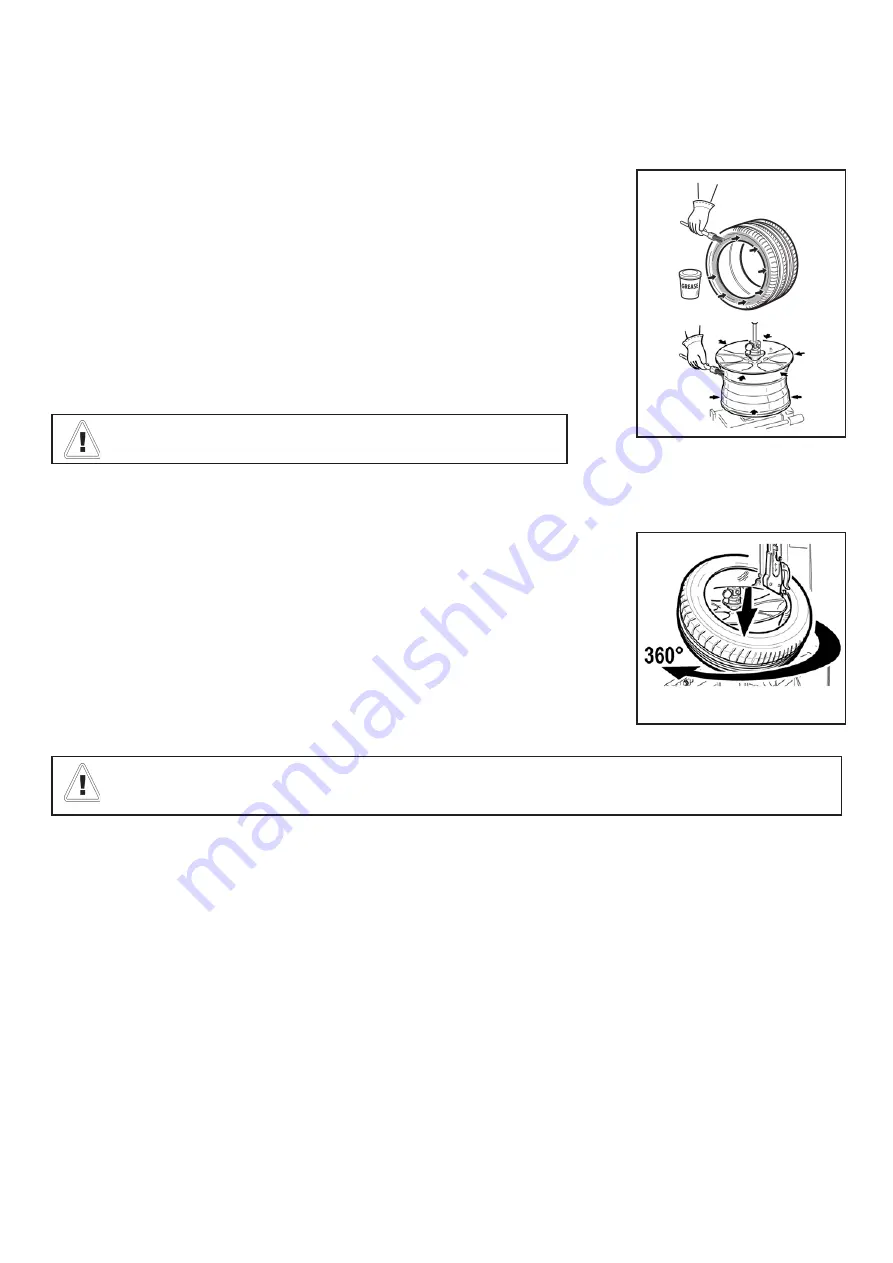

- Carefully lubricate the whole inner surface of the rim and the beads of the tyre, both

externally and internally right around the circumference, for a thickness of at least 30

mm. (Fig. 15)

If there is a sensor, do not let it come into contact with the lubricant

- Swing in the horizontal arm until the tool is positioned correctly compared to the rim.

- Position the tyre horizontally on the rim, slightly tilted downwards to the “3 o’clock”

position (fig. 16).

MOUNTING STANDARD TYRES

Fig. 15

NOTE: If you have difficulties in manually accompanying the bead, you can use the mobile bead presser in the “5

o’clock” position.

Fig. 16

Make sure the bead of the tyre rests on the “shoe” shaped part of the tool and under the grub screw in the

opposite part of the tool.

-Press the rotation pedal to turn the tyre clockwise by 360°

-Manually press the tyre in the “5 o’clock” position until the bead is forced to the height of the channel and keep pressing

it until it reaches position 8 after turning, so that the tyre does not lift while it turns; continue to turn the tyre until the lower

bead has fitted completely in place.

ATTENTION:

Make sure the tyre and the rim move together as one.

LOWER BEAD