38

code HC0100.00GB ed.A-1509

HY

AQUAPUMP HYBRID

HYBRID HEATER

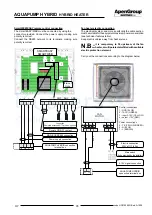

5.9. Fan Heater Operation

For operation modes 0 and 3, that provide for the combination

with one or more fan heaters code ABXXXIT-00H0, in addition

to the management of boiler and heat pump operation, a 0-10V

signal is sent to the fan heater for the automatic management

of the rotation speed of fans.

The rotation speed is controlled according to the following

parameters that can be set on boiler CPU_PLUS PCB.

Par.

Description

Default value

H12

Minimum speed voltage

4 V

H13

Maximum speed voltage

10.0 V

H18

Conditioning voltage

4 V

H19

Minimum speed temperature

35°C

H20

Maximum speed temperature

60°C

During operation in heating mode, the value of 0-10V signal

sent to the fan heater depends of the reading of AQUAPUMP

water delivery temperature probe (NTC1 probe - boiler delivery

probe) and varies linearly between the minimum voltage value

(par.H12) at the temperature corresponding to the minimum

speed (par.H19) and the maximum voltage value (par.H13) at

the temperature corresponding to the maximum speed (par.

H20) as described in the graph below.

During operation in conditioning mode, the voltage value sent

to the fan heater is a value corresponding to par. H18.

During operation in domestic hot water production mode, the

voltage value sent to the fan heater is 0V, therefore ventilation

will be interrupted as long as DHW production is required.

To change fan heater speed adjustment parameters, refer to

paragraph (6.10).

5.10.

Hydraulic circuit filling

Filling or water replenishment operations are the same for all

models.

FILLING:

•

Make sure that connections between indoor unit/system

and AQUAPUMP HYBRID have been carried out correctly,

respecting delivery and return direction;

•

Make sure that automatic vent valves, placed on the

circulator or on the boiler and on the fan heater battery/

ies are open.

•

Using an effective filling system, connect the system to a

pump for system test with reservoir filled with water and

glycol (if required). Load the mix until a pressure of approx.

2 bar is reached.

•

Vent the pipe;

•

When venting operation is over check, through the display,

that the pressure inside the circuit is greater than 1bar; lower

values will cause an F80 because of the activation of water

minimum pressure switch [calibration 0.6bar].

Water-glycol mix restoration

In the event of water leakage and/or need to refill the hydraulic

circuit, after having detected and solved any leakages, it is

necessary to restore water-glycol mix by following the instructions

described above.

GLYCOL

For its machines, APEN GROUP tested and recommends to use

ALPHI 11

glycol by Fernox; the following KITS contain packs

with different capacity:

code

capacity

C07200-05

5 litres

C07200-25

25 litres

The use of glycol having different chemical composition

shall invalidate the exchanger warranty.

N.B. The indicated glycol percentages refer to the parts contained

in the mix (water/glycol) and not in addition to water, e.g.: a

10-litre mix with 30% glycol is composed of 7 litres of water

(70%) and 3 litres of glycol (30%).

NOTE: Glycol percentages and limit temperatures indicated

on page 23 have information purposes; we remind that the

boiler is certified for use with external temperatures up to,

and not exceeding, -15°C.

V

H13

H12

H19

H20

T

[°C]

Содержание Aermax Series

Страница 2: ...2 code HC0100 00GB ed A 1509 HY AQUAPUMP HYBRID HYBRID HEATER...

Страница 4: ...4 code HC0100 00GB ed A 1509 HY AQUAPUMP HYBRID HYBRID HEATER...

Страница 5: ...5 code HC0100 00GB ed A 1509 HY AQUAPUMP HYBRID HYBRID HEATER...

Страница 6: ...6 code HC0100 00GB ed A 1509 HY AQUAPUMP HYBRID HYBRID HEATER...

Страница 60: ...60 code HC0100 00GB ed A 1509 HY AQUAPUMP HYBRID HYBRID HEATER...