18

Temposonics

®

GB-Series SSI

Operation Manual

5. Operation

5.1 Getting started

The sensor is factory-set to its order sizes and adjusted, i.e. the dis

-

tance between magnet and flange is specified in resolution steps.

Example: SSI value 4000 at the start of measuring range 40 mm with

a resolution of 10 µm

NOTICE

If necessary, the SSI sensors can be re-adjusted using

the service tool described below.

5.2

Programming and configuration

SSI interface

The interface of Temposonics

®

position sensors corresponds to SSI

industry standard for absolute encoders. Its displacement value is

encoded in a 24 / 25 bit binary or gray format and transmitted RS422

compatible via 4 wires – independent of data width of the code (reso

-

lution).

The absolute, parallel position data is continually updated by the

sensor and converted by the shift-register into a serial bit stream

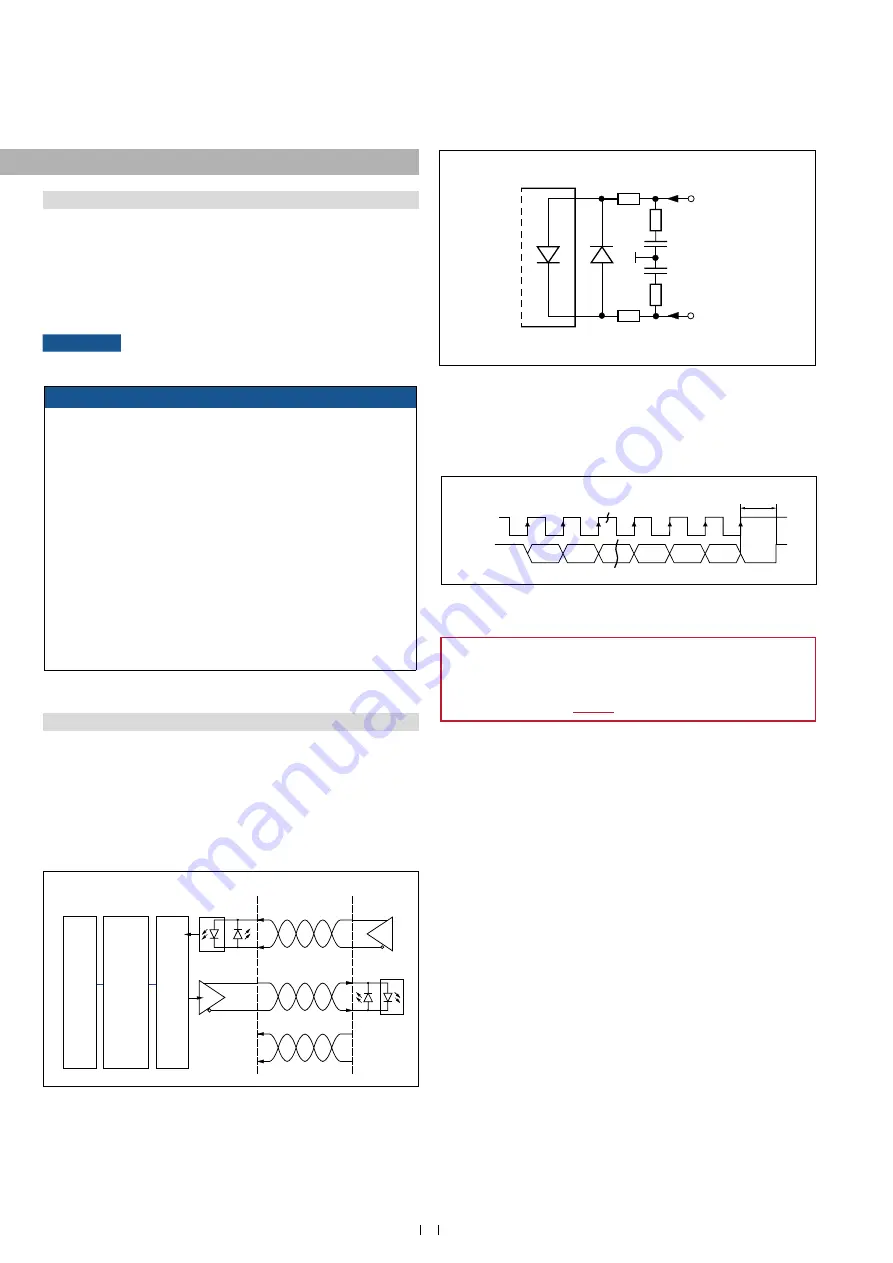

Fig. 23:

Schematic connection

Fig. 24:

Input wiring clock (+) / clock (

−)

Fig. 25:

Timing diagram

MTS Sensors programming tools

Temposonics

®

position sensors can be adapted to modified

measurement tasks very easily via the connecting leads – without

opening the sensor. For this, the MTS Sensors programming kit is

This chapter describes “programming and configuration” of the

GB SSI sensor via cable connection.

“Programming and configuration” via Bluetooth

®

connection are

NOTICE1

Observe during commissioning

1. Before initial switch-on, check carefully if the sensor has been

connected correctly.

2. Position the magnet in the measuring range of the sensor

during first commissioning and after replacement of the magnet.

3. Ensure that the sensor control system cannot react in an

uncontrolled way when switching on.

4. Ensure that the sensor is ready and in operation mode after

switching on

.

5. Check the pre-set span start and end values of the measuring

range (Fig. 17) and correct them via the customer’s control

system if necessary, or via the MTS Sensors service tool.

The operation of the service tool is described in detail on the

following pages.

Sensor input

91 Ω

7 mA

Clock (+)

100 Ω

LED

100 Ω

Clock (−)

91 Ω

Optocoupler

2 V

1 nF

1 nF

Clock (+)

Data (+)

MSB

LSB

Clock interval min. 16 µs

Logic diagram

Sensor

Controller

Clock (+)

Clock (−)

Optocoupler

Driver

Data (+)

Data (−)

+24 VDC

0 V

ASIC for parallel and absolute position data

Microprocessor system position value = 24 / 25 bit

binar

y or gray

Shift register

parallel serial converter