25 MAY 2009

Page 21

000744MAN-02

LINE SET INTERCONNECT TUBING

Once the outside loops have been installed and run into

the building, the piping to the ports on the unit can be

constructed. Each line set has a liquid line and a vapour line.

The vapour line is 1/2” (OD) and the liquid line is 1/2” (OD). For

horizontal loops, both lines are 1/2” (OD), reduce one of the

lines in each line set down to 3/8” (OD) before running the lines

over to the heat pump. These reduced lines will be the liquid

line for each line set.

Do a final pressure check on each line set and then

remove the pressure and cut the ends off the lines. The heat

pump has ports labeled Liquid 1 to 5 and Vapour 1 to 5. Run

each line set over to the designated ports on the heat pump.

Refer to

Diagram 000769CDG

for more information on how to

connect to the heat pump.

The tubing used for this procedure must be refrigeration

tubing (cleaned & dehydrated) suitable for the job. Every effort

must also be made to insure that the tubing does not become

contaminated during installation. We recommend that caps be

placed on the open ends of tubing immediately after cuts are

made and that these caps are only removed after all bends have

been made and the pipe fixed in its permanent location ready to

make the silver soldered joints. It is very important to keep a

refrigeration system perfectly clean and dry. Removing the caps

just prior to silver soldering will ensure minimum exposure to

the humidity in the atmosphere.

PIPE INSULATION

All line set piping inside the structure (between the

structure entry point and the heat pump) should be insulated

with 3/8” thick closed cell pipe insulation to prevent

condensation and dripping onto floors or walls during the

heating season. It can be slid onto the capped tubing without

having to slice it down the side. Ensure that any joints in in the

line sets are accessible for leak testing.

Liquid and Vapour ports and any remaining exposed tubing

should be insulated with 3/8” thick closed cell pipe insulation

once the silver soldering and pressure testing is complete.

Ensure that all individual pieces of pipe insulation are glued to

each other so there are no air gaps.

SILVER SOLDERING LINE SETS

Once all the line sets have been routed, insulated and

fastened in place, the connections to the heat pump ports can

be made. Remove the pressure from the heat pump and cut the

ends off of the Liquid and Vapour ports. Remove the caps from

the line set tubing. The line sets can be connected to the ports

on the heat pump using couplings, or alternately the tubing can

be "swaged". The joints should be silver soldered with 5%

silfos.

AMERICAN DREAM Geothermal absolutely requires

that dry nitrogen be bled through the system during all

silver soldering procedures so that no oxidation occurs on

the inside of the copper tubing.

The service ports on the unit

can be used to connect the nitrogen with a refrigeration

manifold.

If necessary, a damp clothe can be wrapped around the

each of the ports to prevent melting the grommet when silver

soldering. Ensure that no water enters any of the ports or

tubing.

PRESSURE TESTING

Once all connections are complete, the system should be

pressure tested to

100PSIG (690kPa)

with dry nitrogen. Check

all joints at the unit and any made in the interconnect tubing for

leaks using soap suds, Spray nine, etc. It is important not to

bypass this step as vacuuming the system with a leak will be

impossible and attempting to do so will introduce moisture into

the system, making the vacuum process take much longer than

if the leak had been found and repaired first.

VACUUMING THE SYSTEM

Remove the pressure from the system and connect the

vacuum pump to the refrigeration manifold. Tighten all hose

connections, open the valves on the manifold and start the

vacuum pump.

Vacuum the system until the reading on an electronic

vacuum gauge remains below 500 microns for a period of 5

minutes after the vacuum pump is shut off and the system

sealed.

CHARGING THE SYSTEM

Once the system has been vacuumed, refrigerant can be

added by weighing in 1/3 of the prescribed refrigerant charge

into the low side of the system. Start the heat pump in the

heating mode and continue to add refrigerant as a liquid at a

rate of no more than 1 lb. per minute until the prescribed charge

is reached.

Alternately, before the machine is started, the entire

charge can be weighed into the system through the high side of

the system.

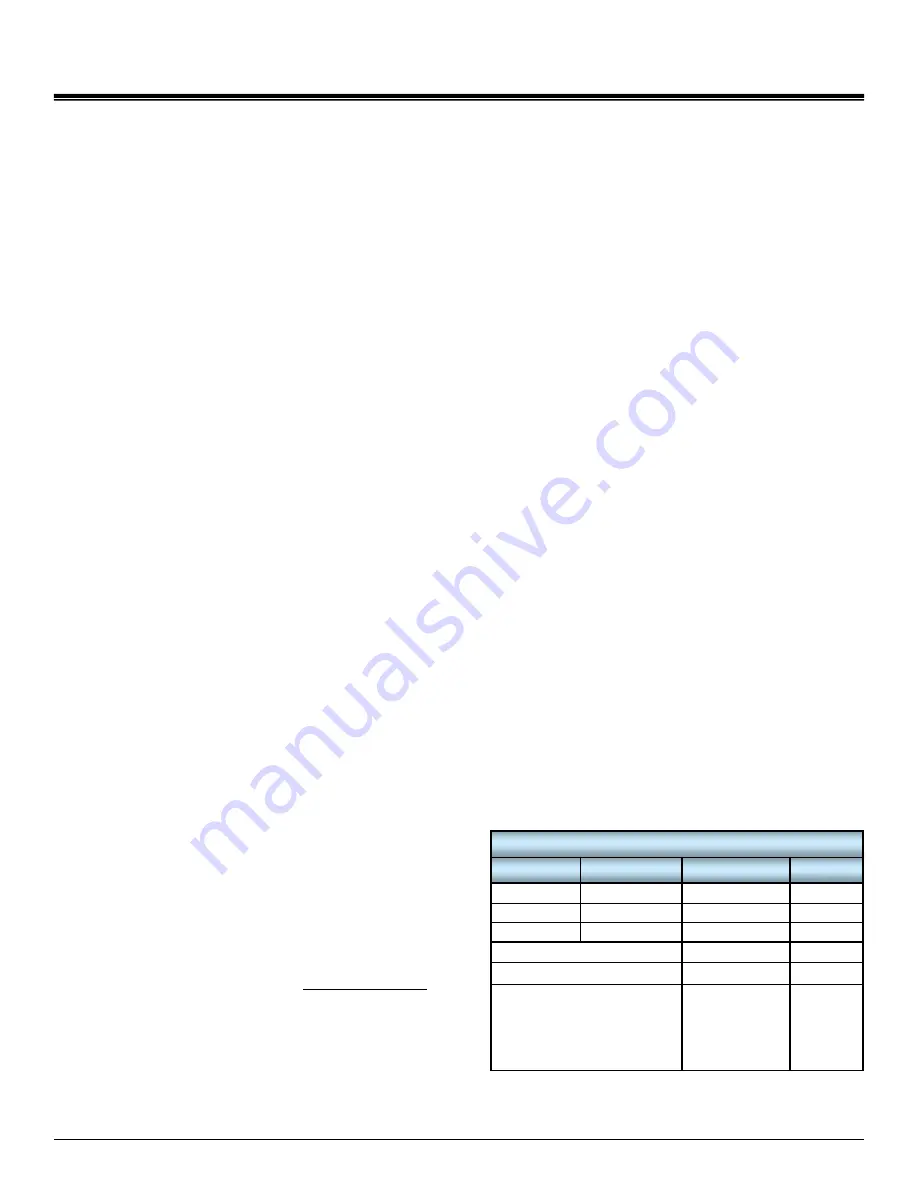

TABLE 16

shows the typical charge per unit size.

This allows for:

20ft of distance (40ft of pipe) interconnect tubing from

the unit to the wall,

20ft of distance from the wall to the borehole /trench,

a standard loop (100ft borehole or 150ft trench).

Additional refrigerant is required as per

TABLE 16

if the

installation exceeds these parameters.

Loop Connection & Charging

TABLE 16 - Charge Chart

Model

Size (tons)

Lbs.

kg

45

3

12

5.4

55

4

16

7.3

65

5

20

9.1

Extra loop (borehole)

1

0.5

Extra loop (trench)

1.5

0.7

Extra distance to borehole

Extra depth of borehole

Extra distance to trench

Extra length of trench

Extra distance in structure

0.1oz per foot

0.003

Содержание Copper Series

Страница 9: ...25 MAY 2009 Page 9 000744MAN 02...

Страница 10: ...Page 10 000744MAN 02 25 MAY 2009...

Страница 13: ...25 MAY 2009 Page 13 000744MAN 02...

Страница 16: ...Page 16 000744MAN 02 25 MAY 2009...

Страница 18: ...Page 18 000744MAN 02 25 MAY 2009...

Страница 19: ...25 MAY 2009 Page 19 000744MAN 02...

Страница 20: ...Page 20 000744MAN 02 25 MAY 2009...

Страница 22: ...Page 22 000744MAN 02 25 MAY 2009...

Страница 45: ...25 MAY 2009 Page 45 000744MAN 02 REFRIGERATION CIRCUIT DIAGRAMS...

Страница 46: ...Page 46 000744MAN 02 25 MAY 2009 REFRIGERATION CIRCUIT DIAGRAMS continued...

Страница 47: ...25 MAY 2009 Page 47 000744MAN 02 REFRIGERATION CIRCUIT DIAGRAMS continued...

Страница 53: ...25 MAY 2009 Page 53 000744MAN 02 ELECTRICAL DIAGRAMS 230 1 60...

Страница 54: ...Page 54 000744MAN 02 25 MAY 2009 ELECTRICAL DIAGRAMS 230 1 60 continued...

Страница 55: ...25 MAY 2009 Page 55 000744MAN 02 CASE DETAILS Front View Back View Left Side View Right Side View...

Страница 56: ...Page 56 000744MAN 02 25 MAY 2009 Top View Size 2 3 4 Ton CASE DETAILS continued Top View Size 5 Ton...

Страница 58: ...Page 58 000744MAN 02 25 MAY 2009...

Страница 59: ...25 MAY 2009 Page 59 000744MAN 02...