5

. WATER SUPPLY

: This machine must have a water

supply meeting or exceeding the maximum discharge

volume specified in the PERFORMANCE section, and

a minimum water inlet pressure specified in the

GENERAL section of the

MODEL

SPECIFICATIONS

.

6.

BARRIER

: We recommend a barrier be installed

between the machine and wash area to prevent

moisture from coming in direct contact with electrical

controls, motors and transformers. This will increase

the machine’s life and lessen electrical problems.

7.

WATER CONDITIONS

: Local water conditions affect

the coil adversely more than any other element. In

areas where troublesome conditions may exist with

like equipment (such as water heaters), we

recommend the use of a water softener.

8

. FREEZING:

This machine must be protected from

freezing according to STORAGE section of

MACHINE

MAINTENANCE

.

9.

COLD WEATHER

: As the weather becomes colder,

fuel becomes thicker and may become so viscous

that the fuel will not flow properly. As viscosity

increases, the thicker oil can cause delayed ignition,

poor spray patterns, and rumbling fires. As moisture

will quickly destroy fuel pumps, make certain that

tank openings are secure and moisture cannot enter.

In cold weather areas, frost build up will occur in fuel

tanks. As the weather warms it turns to condensate,

and the water will be in the tank. Keep the tank clear

of water, as moisture reaching the fuel pump will

cause rust, and the pump will bind. A full fuel tank

will lessen condensation build up.

10

. CHEMICALS:

Mix chemicals per the chemical

manufacturers printed directions. Follow all mixing,

handling, application, and disposal instructions.

Wear gloves, boots, goggles, and protective clothing

appropriate for the chemical being used

WARNING:

This machine emits carbon monoxide,

and deadly gas, and must be vented if used in an

enclosed area. Improper venting can cause poor

combustion, delayed ignition, down drafts, and the

possibility of freezing the coil. Contact your distributor

or local heating and air conditioning dealer for proper

materials. Local codes must be observed.

The information contained herein is offered for reference

only. You must comply with local codes and

investigate through your gas and other utility

companies when installing, as there may be some

special local requirements you must comply with.

Also see ANSI Z223.

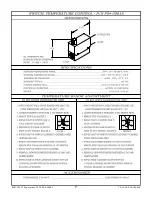

1.

DRAFT DIVERTERS

: (STACKED CLEANERS)

Oil fired machines use a force air burner. The oil burner

can be influenced by “Natural Draft” even though they

have their own fan. A Bell type draft diverter must be

used here also.

A. A draft diverter must be used on all cleaners that are

stacked. This includes any chimney even if not

expelled to the outside.

B. Use a draft diverter of the inverted funnel or bell type

that meets all codes for capacity and materials. Mount

the draft diverter directly to the stacking flange on

the machine

C.

The draft diverter’s function is to insure that the

barometric pressures are as close to the same as

possible at the air inlet and outlet to the coil and will

not be changed by either up drafts or down drafts.

08-19-04 Z08-02830C

6

WARNING:

CARBON MONOXIDE

HAZARD

THIS MACHINE IS

NOT

TO BE CONNECTED

TO A

TYPE B

GAS VENT.

NE PAS RACCORDER CET APPAREIL À UN

TUYAU D’ÉVACUATION DE GAZ DU TYPE B.

VENTING

08-15-03 Z08-02830

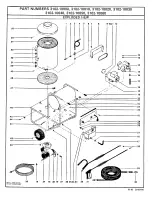

Содержание 3102 Series

Страница 1: ...P O Box 288 105 Broad Street Alcester SD 57001 800 255 6823 www alkota com OLD VALUES NEW IDEAS 3102 ...

Страница 21: ...12 12 02 Z08 00064S ECN 02897 Supersedes 09 00 Z08 00064 7 ...

Страница 22: ...09 00 Z08 00064 ECN 02311 7 ...

Страница 25: ......

Страница 26: ......

Страница 37: ......

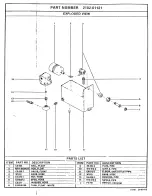

Страница 42: ...06 13 06 Z08 00061 BREAKDOWN BURNER OIL 115V 1PH 60HZ EXPLODED VIEW P N V00 17365 2 Supersedes 04 92 Z08 00061 ...

Страница 43: ...4 ...

Страница 44: ...14 ...

Страница 47: ......

Страница 48: ......

Страница 50: ......