1.

Rinse the chemical line by inserting the screen into a

container of clear water and open the metering valve 1

minute to clean it of any remaining residue. Be sure

the chemical metering valve is closed when finished.

2.

Check the position of the ball valve (if so equipped) on

the outlet of the float tank assuring it is in the

closed position.

3.

Attach an air chuck to the air valve stem on the pump

assembly. With the trigger gun in the open position,

apply air until a mixture of air and very little water is

coming from the gun wand Then turn switch to the

“BURNER” position and depress the vacuum switch.

Run it for 45 seconds allowing any remaining water to

turn to steam. Allow air to blow for 60 seconds. Turn

switch to the “OFF” position.

4.

Remove the air chuck.

5.

Fill a 1-gallon container with Ethylene Glycol type

antifreeze. Minimum should be a mixture of ½

antifreeze and ½ water strength before each use, as

the antifreeze will dilute with use.

6.

FLOAT TANK EQUIPPED:

Pour the anti-freeze solution

into the float tank.

7.

WITHOUT FLOAT TANK:

Install a 2-ft. Garden hose

to the water inlet. Insert the other end into a container

of antifreeze solution.

8.

Turn on the switch to the “PUMP” position.

9.

Turn off the switch just prior to running out of antifreeze

mixture.

10. Disconnect electrical supply.

11 Fill the fuel tank with kerosene or #1 or #2 diesel.

12 It is recommended to install a coil cover to keep coil

free of debris

13 Drain the float tank.

14 Place machine in a dry place protected from weather

condition.

08-19-04 Z08-02830H

STORAGE

12

PART NO. DESCRIPTION

Y02-00001 ……..... 0-1000 PSI (69 BAR) Pressure Gauge

NOTE: All Gauges are Glycerin Filled ¼ NPT

Z01-00070-1…….3/8” x 100 Yards Thread Tape

1.

Connect machine to an electrically grounded circuit

that is fuse or circuit breaker protected.

2.

Connect machine to a pressurized water supply

meeting the requirements specified in the GENERAL

section of the

MODEL

SPECIFICATIONS

.

3.

Turn on the water supply.

4.

Check the float tank (if so equipped) to assure it is

full and the float valve shuts off securely.

5.

Check the position of the ball valve (if so equipped)

on outlet line of the float tank assuring it is in the

open position.

6.

Remove spray tip from gun assembly.

7. With the gun assembly in hand (on trigger gun models

hold the trigger gun valve in open position) and with a

good flow of water turn switch to the PUMP position

CAUTION

: A good flow of water must be flowing from

the end of a gun within 30 seconds, before proceeding.

Lack of water can cause water pump damage.

CAUTION:

DO NOT RUN PUMP WITHOUT WATER,

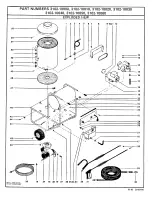

ACCESORIES

OPEN

CLOSED

BALL VALVE POSITION

FLUSHING

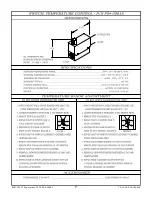

WARNING: ELECTRICAL

SHOCK HAZARD

Содержание 3102 Series

Страница 1: ...P O Box 288 105 Broad Street Alcester SD 57001 800 255 6823 www alkota com OLD VALUES NEW IDEAS 3102 ...

Страница 21: ...12 12 02 Z08 00064S ECN 02897 Supersedes 09 00 Z08 00064 7 ...

Страница 22: ...09 00 Z08 00064 ECN 02311 7 ...

Страница 25: ......

Страница 26: ......

Страница 37: ......

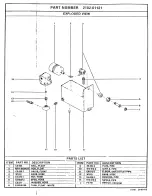

Страница 42: ...06 13 06 Z08 00061 BREAKDOWN BURNER OIL 115V 1PH 60HZ EXPLODED VIEW P N V00 17365 2 Supersedes 04 92 Z08 00061 ...

Страница 43: ...4 ...

Страница 44: ...14 ...

Страница 47: ......

Страница 48: ......

Страница 50: ......