OIL BURNER MAINTENANCE

OIL FIRED CLEANERS

08-05-03 Z08-00062

ECN-02981 Supersedes 06-05-01 Z08-00062

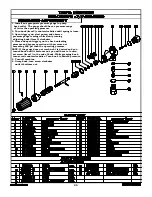

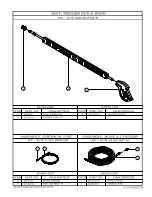

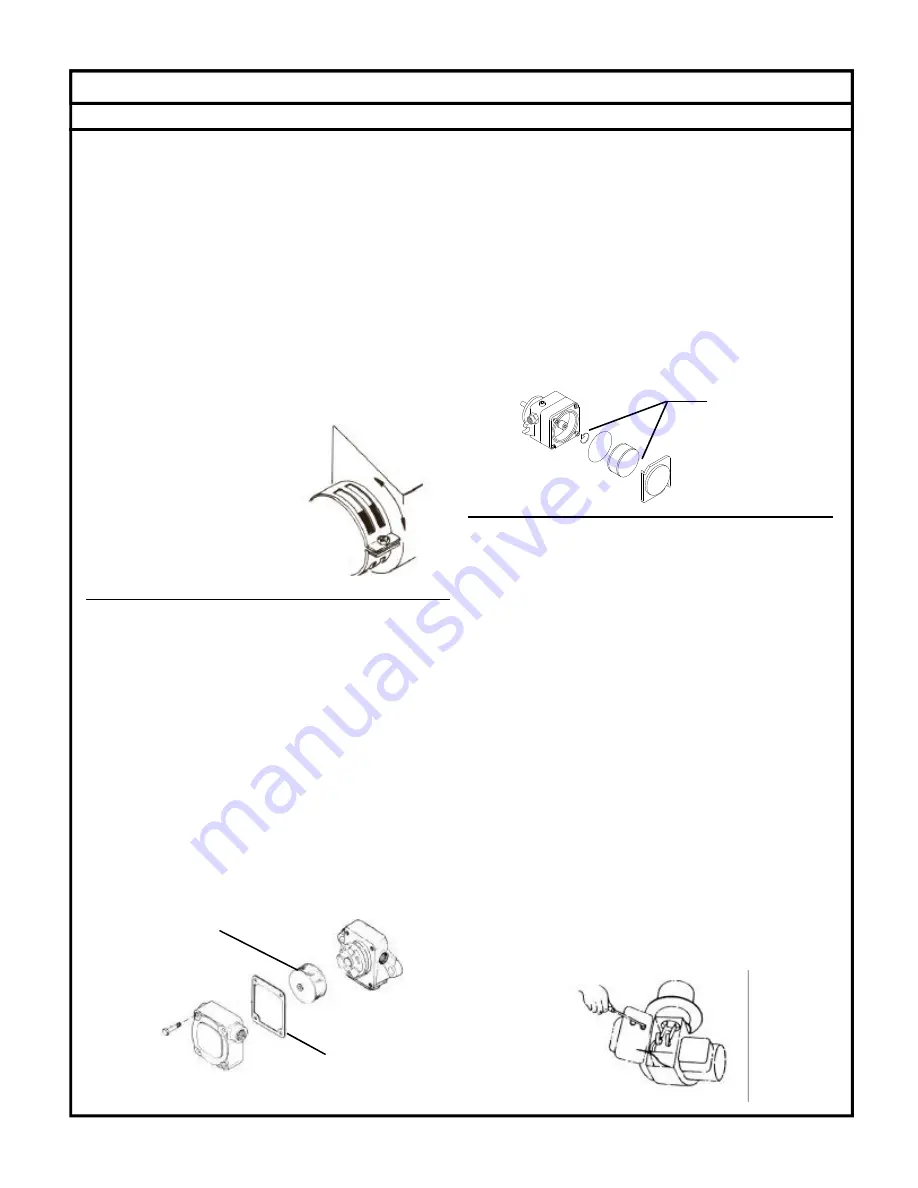

AIR BAND ADJUSTMENT

NOTE: The air band adjustment on this burner

has been preset at the factory (elevation

approximately 1400 feet). On equipment installed

where elevation is substantially different, the air

band(s) must be readjusted.

1. Loosen the cap screw retaining the air bands.

2. Move the air bands as indicated below with

the machine in operation.

NOTE: The air band should be set so the

exhaust gives the smoke spot specified in the

GENERAL section of the

MACHINE

SPECIFICATIONS

on a Shell-Bacharach scale.

If a smoke tester is not

available, a smoky

exhaust, oily odor, or

sweet smell indicates

insufficient air while eye-

burning fumes indicate

too much air.

3. Tighten the cap screw

retaining the air bands.

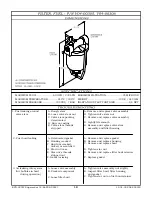

FUEL PUMP FILTER

SUNDSTRAND PUMP

1.

Shut off fuel supply.

2.

Loosen the 4 screws holding the cover to the

fuel pump housing.

3.

Take cover and cover gasket off and pull

strainer off of pump housing.

4.

Clean out any dirt remaining in the bottom of

strainer cover. If there is evidence of rust

inside of the unit, be sure to remove water in

supply tank and fuel filter.

5.

Turn on fuel supply. Failure to do so will result

in fuel pump damage.

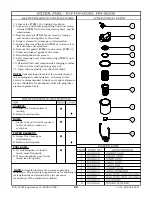

DANFOSS PUMP

1.

Shut off fuel supply.

2.

Loosen the 2 screws with 7/64 allen wrench

one turn.

3.

Turn cover counter clockwise and pull strainer

and cover off of pump housing.

4.

Clean out any dirt remaining in the bottom of

strainer cover. If there is evidence of rust

inside of the unit, be sure to remove water in

supply tank and fuel filter.

5.

Reinstall reverse of removal.

6.

Turn on fuel supp

ly.

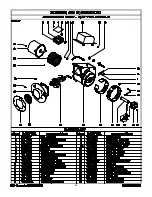

TRANSFORMER TEST

1. Remove burner junction box cover.

2. Turn on burner and make sure ignition

transformer is receiving rated voltage.

3. Turn off burner.

4. Loosen screw and swing transformer away from

burner gun assembly.

5. Turn on burner.

6. Short the high voltage terminals.

CAUTION

: Use screwdriver with a well

insulated handle to avoid shock.

7. Open gap by drawing screwdriver away from

one electrode while touching the other.

8. The spark should jump between 5/8 inches

and 3/4 inches, if it doesn’t jump, replace

the transformer.

9. Turn burner off.

10.Partially close transformer. Check if buss bars

align and contact transformer electrodes. If

buss bars do not contact, see Buss Bar

Alignment.

11.Close transformer, r

eposition retainer clip and

tighten screw

.

PART NUMBER

V00-99004

PART NUMBER

V00-14283-2

PART NUMBER

V00-14283-5

Содержание 3102 Series

Страница 1: ...P O Box 288 105 Broad Street Alcester SD 57001 800 255 6823 www alkota com OLD VALUES NEW IDEAS 3102 ...

Страница 21: ...12 12 02 Z08 00064S ECN 02897 Supersedes 09 00 Z08 00064 7 ...

Страница 22: ...09 00 Z08 00064 ECN 02311 7 ...

Страница 25: ......

Страница 26: ......

Страница 37: ......

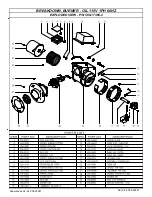

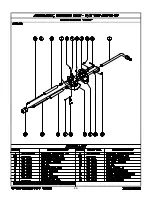

Страница 42: ...06 13 06 Z08 00061 BREAKDOWN BURNER OIL 115V 1PH 60HZ EXPLODED VIEW P N V00 17365 2 Supersedes 04 92 Z08 00061 ...

Страница 43: ...4 ...

Страница 44: ...14 ...

Страница 47: ......

Страница 48: ......

Страница 50: ......