♦

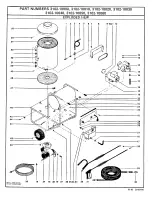

FLOAT TANK BALL VALVE:

Check the position of

the ball valve on the outlet side of the float tank (if so

equipped) that it is in the open position.

1

Select temperature (if so equipped).

2

With the gun assembly in hand (on trigger gun models

hold the trigger gun valve in open position) and with

a good flow of water turn the switch to the “pump”

position.

CAUTION:

A good flow of water must be flowing from

the end of a gun for 30 seconds, before proceeding.

Lack of water can cause damage to the water pump

and like components.

CAUTION:

On a machine equipped with a trigger gun

valve, if the trigger gun valve remains in the closed

position for more than 3 minutes, water pump damage

may occur.

3

Turn the switch to the “burner” position.

CAUTION:

Do not run the machine with the burner

switch in the on position when the fuel tank is empty

or with tank valves closed. This will cause damage

to the fuel pump and void warranty.

CAUTION:

Do not operate with the trigger gun valve

closed for more than 3 minutes or water pump damage

may occur.

TO

CLEAN

:

A

Start on the lower portion of the area to be cleaned

and work up using long, even, overlapping strokes.

B

Dirt is generally removed easily if grease and/or

oil are not present. However if grease and/or oil

are present, hot water and chemical will

accelerate in the cleaning process.

4

TO APPLY CHEMICAL

:

CHEMICAL

: Use factory recommended chemicals

for best cleaning action and for extended pump life.

Contact your dealer for chemicals available. Follow

instructions on chemical container.

Mix chemicals per label instructions. Use necessary

safety precautions.

A. Insert chemical screen into chemical container

B. Adjust metering valve (if so equipped).

C. If the gun assembly is equipped with variable or

multiple nozzle assembly, adjust as desired.

TO RINSE:

A. If the machine is equipped with a panel mounted

metering valve, close the chemical metering valve

(if so equipped). NOTE: It is advisable to dip the

chemical screen in a container of clean water

and open the valve 1 minute to clean the valve of

any remaining residue.

B. If the gun assembly is equipped with variable or

multiple nozzle assembly, open and close to clean

nozzle of any remaining residue.

C. After a clear flow of water is noted from the end

of the wand, start from the top, working downward

using long, overlapping strokes.

1

Turn the switch to the pump “position”. (If not already

done so in the cold water rinse.)

2

After cool, clear water is coming from the end of the

wand, turn switch to the “off” position .

3

Turn off the water supply.

4

If freezing conditions may exist, refer to STORAGE

in

MACHINE

MAINTENANCE

.

5

Replace stack cover (if so equipped).

08-19-04 Z08-02830E

8

OPEN

CLOSED

BALL VALVE POSITION

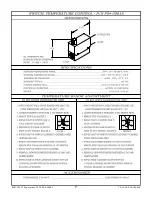

WARNING:

RISK OF INJECTION OR

SEVERE INJURY. KEEP CLEAR OF NOZZLE.

DO NOT DIRECT DISCHARGE STREAM AT

PERSONS. THIS EQUIPMENT IS TO BE USED

ONLY BY TRAINED OPERATORS.

AVERTISSEMENT:

RISQUE D’INJECTION

ET DE BLESSURES GRAVES. SE TENIR À

L’ÉCART DU JET. NE PAS DIRIGER LE JET DE

SOTIE VERS D’AUTRES PERSONNES CONFIER

L’UTILISATION LE JET DE SOTIE VERS

D’AUTRES PERSONNES. CONFIER

L’UTILISATION DE CE MATÉRIEL À UN

OPÉRATEUR QUALIFIÉ.

SHUT-DOWN

08-15-03 Z08-02830

Содержание 3102 Series

Страница 1: ...P O Box 288 105 Broad Street Alcester SD 57001 800 255 6823 www alkota com OLD VALUES NEW IDEAS 3102 ...

Страница 21: ...12 12 02 Z08 00064S ECN 02897 Supersedes 09 00 Z08 00064 7 ...

Страница 22: ...09 00 Z08 00064 ECN 02311 7 ...

Страница 25: ......

Страница 26: ......

Страница 37: ......

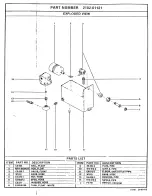

Страница 42: ...06 13 06 Z08 00061 BREAKDOWN BURNER OIL 115V 1PH 60HZ EXPLODED VIEW P N V00 17365 2 Supersedes 04 92 Z08 00061 ...

Страница 43: ...4 ...

Страница 44: ...14 ...

Страница 47: ......

Страница 48: ......

Страница 50: ......