11

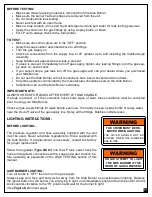

BEFORE TESTING:

•

Make sure that all packing material is removed from the Side Burner.

•

Make sure the burner tie-down straps are removed from the unit.

•

Do not smoke while leak testing.

•

Never leak test with an open flame.

•

Make a soap solution of one part liquid detergent and one part water for leak testing purposes.

•

Apply the solution to the gas fittings by using a spray bottle, or brush.

•

For LP units, always check with a full cylinder.

TO TEST:

•

Make sure all control valves are in the “OFF” position.

•

Apply the soap solution described above to all fittings.

•

Turn the gas supply on.

•

Check all connections from the supply line, or LP cylinder up to and including the manifold pipe

assembly.

•

Soap bubbles will appear where a leak is present.

•

If a leak is present, immediately turn off gas supply, tighten any leaking fittings, turn the gas sup-

ply back on, and recheck.

•

If you cannot stop a gas leak turn off the gas supply and call your dealer where you purchased

your Side Burner.

•

Do not use the Side Burner until all connections have been checked and do not leak.

•

Only those parts recommended by the manufacturer should be used on the Side Burner.

•

Substitution can void the Side Burner’s warranty.

IMPORTANT NOTE:

ALWAYS CHECK FOR LEAKS AFTER EVERY LP TANK CHANGE.

If a leak is present, or if the connection hose shows signs of wear, these conditions must be corrected

prior to using your Side Burner.

Check all gas supply fittings for leaks before each use. It is handy to keep a spray bottle of soapy water

near the shut-off valve of the gas supply line. Spray all the fittings. Bubbles indicate leaks.

LIGHTING INSTRUCTIONS:

BEFORE LIGHTING…

The pressure regulator and hose assembly supplied with the unit

must be used. Never substitute regulators for those supplied with

the Side Burner. If a replacement is necessary, contact the factory

for proper replacement.

Screw the regulator (Type QCC1) into the LP tank. Leak check the

hose and regulator connections with a soap and water solution be-

fore operating as explained on the LEAK TESTING section of this

manual.

SIDE BURNER LIGHTING:

Turn all knobs to “OFF” then turn on the gas supply.

Always keep your face and body as far away from the Side Burner as possible when lighting. Depress

the igniter button for the burner you are trying to light, and immediately push and turn the burner control

knob counter-clockwise to the “HI” position and wait for the burner to light.

(See Figure # 4 on next page)

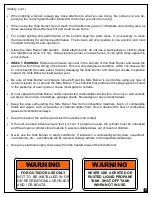

WARNING

THE COVER MUST BE RE-

MOVED WHEN LIGHTING.

THE COVER SHOULD NOT BE

CLOSED WHEN THE BURNERS

ARE IN USE.

WARNING

DO NOT ATTEMPT TO LIGHT

THE SIDE BURNER IF THE

ODOR OF GAS IS PRESENT.

Содержание ALSB-2

Страница 1: ......

Страница 2: ...2 PASTE SERIAL NUMBER LABEL IN THIS LOCATION NOTES BARBEQUE SERIAL NUMBER LABEL ...

Страница 17: ...17 ...

Страница 20: ...20 ...