C N C 4 2 2 0 M a c hi ne Too l Op e ra t ion an d Te st

59

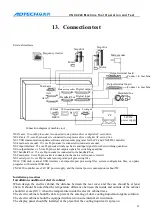

When design the electric cabinet, please reduce the external electrical interference to avoid affecting

the system.

To avoid interference

When the system is designed, we have taken measures to shield space electromagnetism radiation,

absorb impact current, filter power clutter and other measures to avoid interference. It can

prevent the external interference to the system to a certain extent. To ensure that the system

works stably, please take the following measures when install the system:

1: Keep the machine tool away from equipment that may cause interference (e.g. frequency inverter,

AC contactor, static generator, high voltage generator and section device of power lines). At the same

time, connect the switching power supply to the filter separately to improve the interference resistance

of the machine tool (see Fig. 1-4).

2: To supply power for the system through isolation transformer, the machine tool installed with the

system should be grounded, and machine tool and the drive should be connected to separate earth wire

from the connection point.

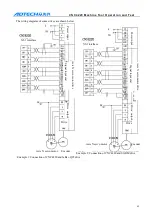

3: Interference suppression: connect RC loop in parallel on both ends of AC coil (0.01μF, 100~200Ω,

as in Fig. 1-5); approach to inductive load when install RC loop; install reverse parallel freewheeling

diode on both ends of DC coil (Fig. 1-6); connect surge absorber in parallel at the winding end of the

AC motor (Fig. 1-7).

Fig. 1-5

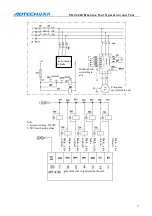

5: To reduce the interference between machine tool signal cable and strong electricity cable, please

follow the rules below for wiring:

Group

Cable type

Wiring requirement

AC power cord

AC coil

A

AC contactor

Bind cables in group A separately from those in

group B and C, keep at least 10cm between

each other, or shield the cables in group A

B

DC coil (24VDC)

Bind cables in group B separately from those in

group A, or shield the cables in group B; keep

Filter

Switching power supply

Surge

absorber

Fig. 1-4

Fig. 1-5

Fig. 1-7

Fig. 16