34

8.7 LIST OF ANOMALIES FOR FORCED CIRCULATION SYSTEMS

8.6 SYSTEM INSPECTION AND MAINTENANCE

FORCED CIRCULATION

The solar collector does not require particular maintenance, it is

essential to carry out a periodic visual check of the collector itself

(cleaning or absence of damage or breakages) and a check of

the fixings and fittings.

In case of accidental leaks from the collector, the repair can

bedone with a normal copper welding (contact the manufacturer

for advice).

Periodically check that the system pressure remains constant

during normal operation.

Check every year (at the beginning of winter) the concentration

of antifreeze liquid with the appropriate tool that the limit value of

-26 °C is not exceeded.

Check the pH of the antifreeze solution every year (it must be

pH> 7.0).

In any case, the antifreeze fluid must be replaced every 5 years.

If there are noises inside the circuit, check and eliminate anyì

residual air present.

Check the integrity of the anti-corrosion anode in the boiler.

Pump operation: check that the pump starts running in the night /

day passage (presence of solar radiation) and that it stops in the

reverse passages.

If there is a difference between delivery and return of the circuit

greater than 60 °C, adjust the pump flow rate.

Never fill the circuit with water only.

Failed inspections and maintenance can cause damage to the

system and to people, animals or things for which the

manufacturer cannot be held responsible.

The checks must be carried out by an authorized technician

during the annual checks.

ACTIONS ABSOLUTELY FORBIDDEN

FORCED CIRCULATION

The automatic filling of cold water into the circuit is absolutely

forbidden to avoid breakage due to freezing.

There is no warranty coverage.

It is absolutely forbidden to intercept expansion vessels, solar

collectors and safety valves with valves.

It is absolutely forbidden to operate the solar circulator manually

at night or empty, as it causes condensation or problems in the

circulator.

It is absolutely forbidden to install the system yourself without the

help of a qualified installer.

It is absolutely forbidden not to adequately fix the frame to the

underlying structure.

It is absolutely forbidden to put outside or to the elements

anything that is not specifically suitable for the outside, such as:

kettles, electrical equipment, expansion vessels, etc ...

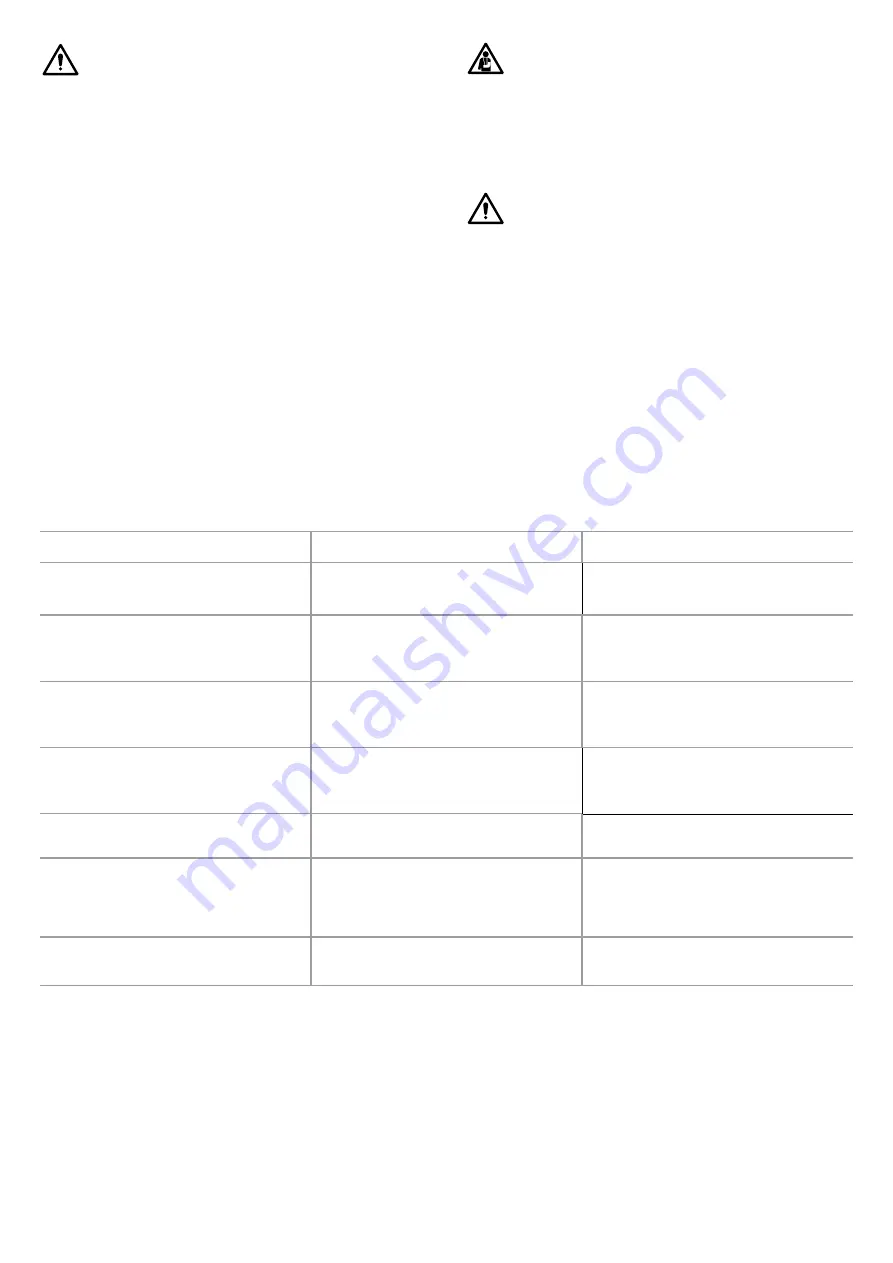

ELENCO ANOMALIE

POSSIBLE CAUSES

POSSIBLE SOLUTIONS

Loss of pressure in the manifold circuit

Loss of any jolly valves present

Water leakage in the circuit due to broken fittings / pipes.

Anomalous leakage of fl uid from the safety valve

Replace the jolly valves with manual relief valves.

Replace the safety valves

Abnormal fluid leaks from the safety valve

Insufficient or damaged expansion vessels Incorrect

pre-charge pressure in the expansion vessel

Incorrect sizing of the collector circuit flow rate

Safety valve failure

Replace or increase the expansion vessels

Remove pressure in the system and put the vessels back

under pressure

Replace the safety valve

Failure of the pump

No mains voltage

Reaching limit temperature of the storage tank or collector

Breakage of collector or storage tank temperature probe

Check the electronic control unit

The control unit manages the limit temperature, everything

will be reset when the temperatures have dropped. Probes

replacement

No hot fluid arriving from the manifold but the pump

is running

Shut-off valves and / or non-return valves closed

Presence of air in the collector circuit

Steam formation in the collector circuit

(pump start delay or fluid flow too low)

Exhaust by means of the manual air vent.

With cold circuit, remove air

Pump start-up delay

Wrong electronic control unit settings.

Inversion of the probes during assembly

Check the settings of the electronic control unit again

Excessive kettle cooling

Non-return valve faulty, the boiler heat rises to the panel)

DHW recirculation pump always running

(where it exists)

Kettle not properly insulated

Check the non-return valve.

Set the recirculation usage time less frequently

(Kettle not supplied by the parent company), isolate the

kettle

Condensation in the panels

Check valve not working, the boiler heat rises to the

panel

Pump on also at night

Reset the operation of the solar circulator to automatic

and not manual.

LIST OF ANOMALIES