4 Repair

4.4.1. Replacement of complete upper arm

135

3HAC022032-001 Revision: E

© Copyri

ght

200

4-2008 ABB.

All rights reserved.

Refitting, upper arm

The procedure below details how to refit the complete upper arm to the robot.

Note! The following procedure also applies to the IRB 4450S.

3. Move the upper arm to a horizontal position.

4. Secure the weight of the upper arm with the lifting

slings and a crane.

5. Remove the tie rod.

Detailed in section

6. Loosen the connectors of motors, axes 4, 5 and 6.

7. Remove the connection box, upper arm from the

motors.

8. Remove the calibration plate, axis 3.

9. Remove the VK covers on both sides of the upper

arm.

Be careful with the bearing beneath the cover! Make

a hole in the outer edge of the cover and bend it away.

10. Undo the KM nuts.

11. Remove the screws.

12. Pull out the shaft with the dismounting tool.

Mark the shafts (left and right)!

Art.no. is specified in

Required equipment on

page 134

13. Remove the sealings and bearings, if damaged.

14. Remove the upper arm from the manipulator.

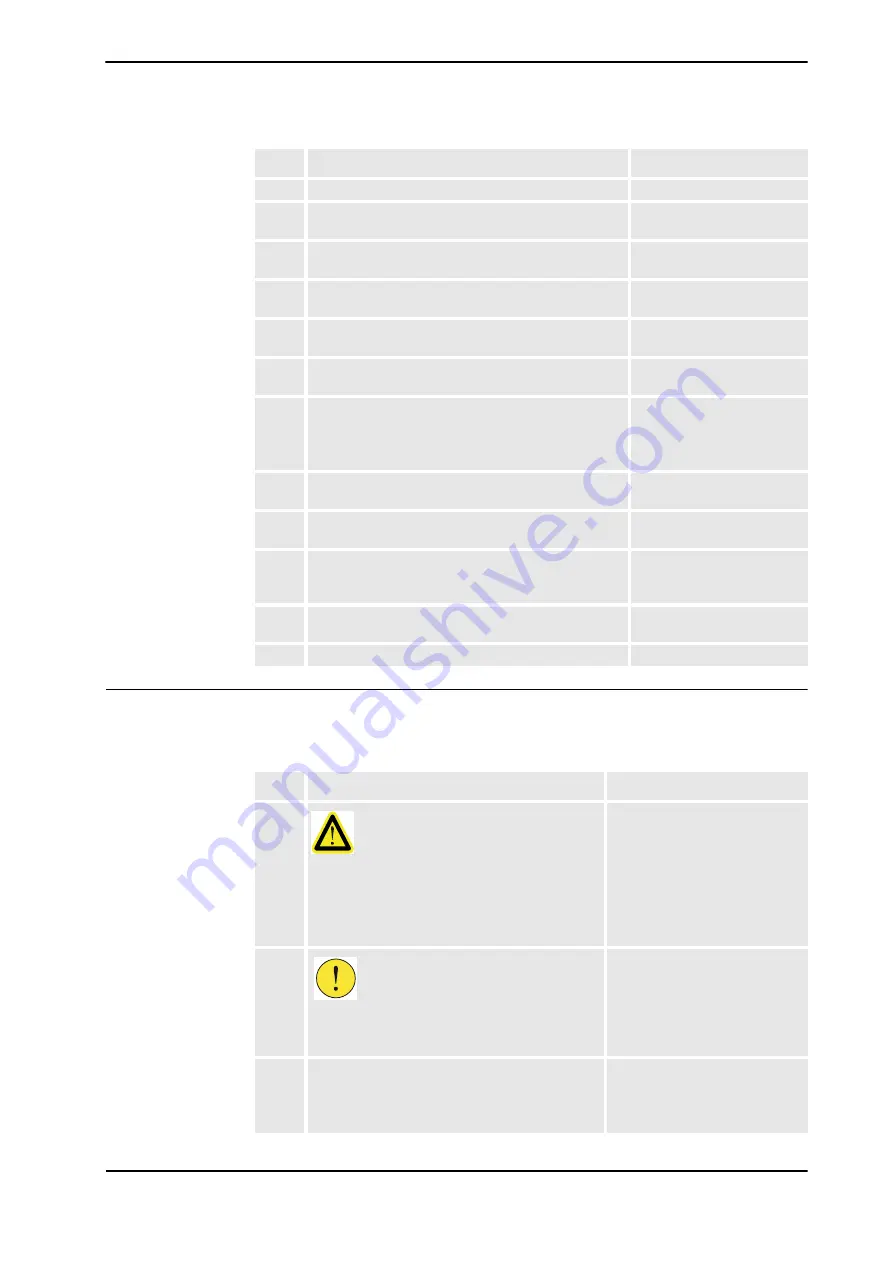

Action

Info/Illustration

Action

Info/Illustration

1.

Turn off all electric power, hydraulic and

pneumatic pressure supplies to the robot!

For Foundry Prime robots: Do not turn off the air

pressure to motors and SMB.

2.

The complete arm system weighs 232 kg! All

lifting equipment used must be sized accordingly!

3. Fit the sealings and the outer ring of the bearings

in the upper arm, if removed.

The bearing must be completely filled with

grease.

Part no. is specified in

.

Continued

Continues on next page

Содержание IRB 4400 - 45

Страница 2: ......

Страница 8: ...Table of Contents 6 3HAC022032 001 Revision E Copyright 2004 2008 ABB All rights reserved ...

Страница 236: ...4 Repair 4 9 2 Repair routines 3HAC022032 001 Revision E 234 Copyright 2004 2008 ABB All rights reserved ...

Страница 256: ...Product documentation M2004 3HAC022032 001 Revision E 254 Copyright 2004 2008 ABB All rights reserved ...

Страница 294: ...7 Part list 7 5 Position switch axis 1 3HAC022032 001 Revision E 292 Copyright 2004 2008 ABB All rights reserved ...

Страница 296: ......

Страница 297: ... Copyright 2004 2006 ABB All rights reserved Foldout 1 ...

Страница 298: ... Copyright 2004 2006 ABB All rights reserved Foldout 2 ...

Страница 299: ... Copyright 2004 2006 ABB All rights reserved Foldout 3 1 ...

Страница 301: ... Copyright 2004 2006 ABB All rights reserved Foldout 4 ...

Страница 302: ... Copyright 2004 2006 ABB All rights reserved Foldout 5 ...

Страница 303: ... Copyright 2004 2006 ABB All rights reserved Foldout 6 1 ...

Страница 304: ... Copyright 2004 2006 ABB All rights reserved Foldout 6 2 ...

Страница 305: ... Copyright 2004 2006 ABB All rights reserved Foldout 6 3 ...

Страница 306: ... Copyright 2004 2006 ABB All rights reserved 4 3 9 R1 SMB R2 SMB R1 G 8 5 7 3hab 3365 1 x Seriemätenhet Foldout 7 ...

Страница 307: ... Copyright 2004 2006 ABB All rights reserved Foldout 8 ...

Страница 309: ...9 Circuit diagram 8 1 Introduction 3HAC022032 001 Revision E 296 Copyright 2004 2008 ABB All rights reserved ...

Страница 311: ... Copyright 2004 2006 ABB All rights reserved List of Contents Location of Connection Point Sheet 101 ...

Страница 312: ... Copyright 2004 2006 ABB All rights reserved Brake Release Unit Serial Measurement Board Sheet 102 ...

Страница 313: ... Copyright 2004 2006 ABB All rights reserved Motor Axis 1 3 Sheet 103 ...

Страница 314: ... Copyright 2004 2006 ABB All rights reserved Feed Back Axis 1 3 Sheet 104 ...

Страница 315: ... Copyright 2004 2006 ABB All rights reserved Motor Axis 4 6 Sheet 105 ...

Страница 316: ... Copyright 2004 2006 ABB All rights reserved Feed Back Axis 4 6 Sheet 106 ...

Страница 317: ... Copyright 2004 2006 ABB All rights reserved Customer Connection Sheet 107 ...

Страница 318: ... Copyright 2004 2006 ABB All rights reserved Pos Indicator Axis 1 Option Sheet 108 ...

Страница 321: ......

Страница 322: ...ABB Robotics S 721 68 VÄSTERÅS SWEDEN Telephone 46 0 21 344000 Telefax 46 0 21 132592 3HAC 022032 001 Revision E en ...