3 Maintenance

3.4.5. Oil change, gearbox axis 5 and 6 (IRB 4400/L10 only)

109

3HAC022032-001 Revision: E

© Copyri

ght

200

4-2008 ABB.

All rights reserved.

Draining oil

The procedure below details how to drain the oil from the wrist unit (axis 5 and 6), robot

version IRB 4400/L10.

When changing gearbox oil, first run the robot for a time to heat up the oil. Warm oil drains

quicker than cold oil.

Changing and draining gearbox oil may require handling hot oil of up to 90 °C! Make sure

that protective gear like goggles and gloves are always worn during this activity.

Also, be aware of possible pressure build up in gearbox! When opening the oil plug, there

may be pressure present in the gearbox, causing oil to spray from the opening!

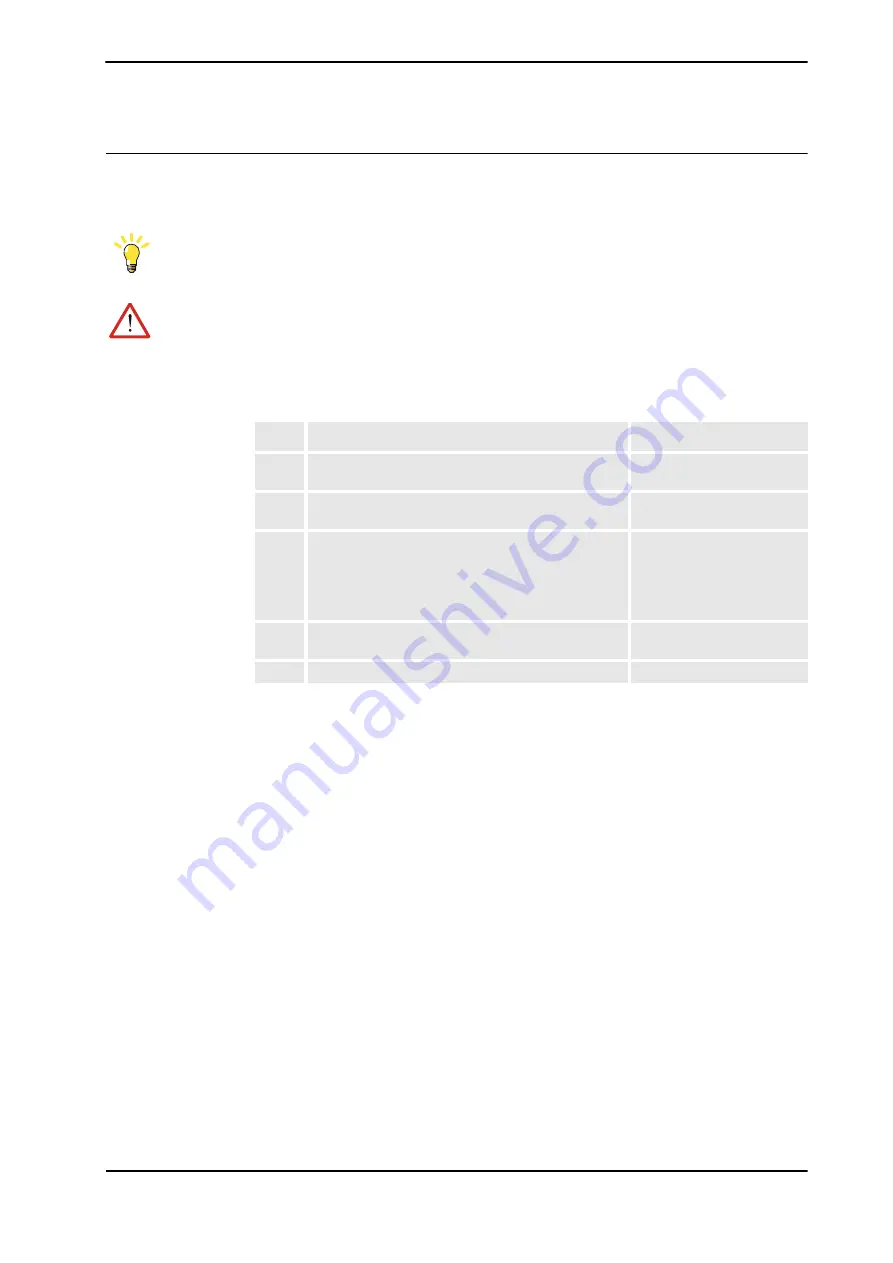

Action

Info/Illustration

1. Move the upper arm to a horizontal position and turn

axis 4 to the calibration position.

2. Remove the oil plug, draining in the wrist.

Shown in the figure

.

3. Turn axis 4 to a position where the oil plug, draining

is faced downwards and drain the oil into an oil

collecting vessel.

Also remove the oil plug, filling, in order to use it as an

air inlet.

Shown in the figure

.

Capacity of vessel is

specified in

.

4. Turn axis 4 another 90° to allow the remaining oil to

be drained.

5. Clean and refit the oil plug, draining.

Continued

Continues on next page

Содержание IRB 4400 - 45

Страница 2: ......

Страница 8: ...Table of Contents 6 3HAC022032 001 Revision E Copyright 2004 2008 ABB All rights reserved ...

Страница 236: ...4 Repair 4 9 2 Repair routines 3HAC022032 001 Revision E 234 Copyright 2004 2008 ABB All rights reserved ...

Страница 256: ...Product documentation M2004 3HAC022032 001 Revision E 254 Copyright 2004 2008 ABB All rights reserved ...

Страница 294: ...7 Part list 7 5 Position switch axis 1 3HAC022032 001 Revision E 292 Copyright 2004 2008 ABB All rights reserved ...

Страница 296: ......

Страница 297: ... Copyright 2004 2006 ABB All rights reserved Foldout 1 ...

Страница 298: ... Copyright 2004 2006 ABB All rights reserved Foldout 2 ...

Страница 299: ... Copyright 2004 2006 ABB All rights reserved Foldout 3 1 ...

Страница 301: ... Copyright 2004 2006 ABB All rights reserved Foldout 4 ...

Страница 302: ... Copyright 2004 2006 ABB All rights reserved Foldout 5 ...

Страница 303: ... Copyright 2004 2006 ABB All rights reserved Foldout 6 1 ...

Страница 304: ... Copyright 2004 2006 ABB All rights reserved Foldout 6 2 ...

Страница 305: ... Copyright 2004 2006 ABB All rights reserved Foldout 6 3 ...

Страница 306: ... Copyright 2004 2006 ABB All rights reserved 4 3 9 R1 SMB R2 SMB R1 G 8 5 7 3hab 3365 1 x Seriemätenhet Foldout 7 ...

Страница 307: ... Copyright 2004 2006 ABB All rights reserved Foldout 8 ...

Страница 309: ...9 Circuit diagram 8 1 Introduction 3HAC022032 001 Revision E 296 Copyright 2004 2008 ABB All rights reserved ...

Страница 311: ... Copyright 2004 2006 ABB All rights reserved List of Contents Location of Connection Point Sheet 101 ...

Страница 312: ... Copyright 2004 2006 ABB All rights reserved Brake Release Unit Serial Measurement Board Sheet 102 ...

Страница 313: ... Copyright 2004 2006 ABB All rights reserved Motor Axis 1 3 Sheet 103 ...

Страница 314: ... Copyright 2004 2006 ABB All rights reserved Feed Back Axis 1 3 Sheet 104 ...

Страница 315: ... Copyright 2004 2006 ABB All rights reserved Motor Axis 4 6 Sheet 105 ...

Страница 316: ... Copyright 2004 2006 ABB All rights reserved Feed Back Axis 4 6 Sheet 106 ...

Страница 317: ... Copyright 2004 2006 ABB All rights reserved Customer Connection Sheet 107 ...

Страница 318: ... Copyright 2004 2006 ABB All rights reserved Pos Indicator Axis 1 Option Sheet 108 ...

Страница 321: ......

Страница 322: ...ABB Robotics S 721 68 VÄSTERÅS SWEDEN Telephone 46 0 21 344000 Telefax 46 0 21 132592 3HAC 022032 001 Revision E en ...