5

•

Do not cover the instruction manual. Keep it on the side of the

water heater or nearby for future reference.

•

Do obtain new warning and instruction labels for placement

on the blanket directly over the existing labels.

•

Do inspect the insulation blanket frequently to make certain it

does not sag, thereby obstructing combustion air flow.

INSTALLATION

REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS WATER HEATER

REQUIRES ABILITY EQUIVALENT TO THAT OF A LICENSED

TRADESMAN IN THE FIELD INVOLVED. PLUMBING, ELECTRICAL

AIR SUPPLY, VENTING AND GAS SUPPLY ARE REQUIRED.

GENERAL

The heater is designed to operate on natural or propane gases.

HOWEVER, MAKE SURE the gas on which the heater will operate

is the same as that specified on the heater model and rating plate.

The installation must conform to these instructions and the local

code authority having jurisdiction. In the absence of local codes,

the installation must conform to the current edition of National

Fuel Gas Code ANSI Z223.1/NFPA 54 and the National Electrical

Code, NFPA 70. The former is available from the Canadian

Standards Association, 8501 East Pleasant Valley Road,

Cleveland, OH 44131, and both documents are available from

the National Fire Protection Association, 1 Batterymarch Park,

Quincy, MA 02269.

GROUNDING

The water heater, when installed, must be grounded in accordance

with local codes, or in the absence of local codes:

The National Electrical Code, NFPA 70

HIGH ALTITUDE INSTALLATION

CAUTION

INSTALLATIONS ABOVE 2000 FT. REQUIRE REPLACEMENT OF

THE BURNER ORIFICE IN ACCORDANCE WITH THE NATIONAL

FUEL GAS CODE (ANSI Z223.1/NFPA 54). FAILURE TO

REPLACE THE ORIFICE COULD RESULT IN IMPROPER AND

INEFFICIENT OPERATION OF THE APPLIANCE, PRODUCING

CARBON MONOXIDE GAS IN EXCESS OF SAFE LIMITS, WHICH

COULD RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

CONTACT YOUR GAS SUPPLIER FOR ANY SPECIFIC

CHANGES WHICH MAY BE REQUIRED IN YOUR AREA.

SOME MODELS ARE SPECIFICALLY BUILT FOR HIGH

ALTITUDE SERVICE.

PLEASE CHECK THE RATING PLATE BEFORE MAKING

CHANGES.

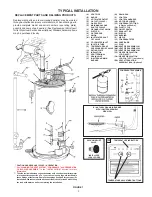

LOCATION OF HEATER

When installing the heater, consideration must be given to proper

location. Location selected should be as close to the wall as

practicable with adequate air supply and as centralized with the

water piping system as possible.

The heater is designed for installation on combustible flooring in

a closet having minimum clearances from combustible material

of: 0" clearance from sides and rear, 5.5" from the front and 12"

from the top. (Standard clearance.) If clearances stated on the

heater differ from standard clearances, install water heater

according to clearances stated on heater.

A minimum clearance of 4" must be allowed for access to

replaceable parts such as the thermostats, drain valve and relief

valve. A top clearance of 24" should be allowed for blower

assembly service.

Adequate clearance for servicing this appliance should be

considered before installation, such as changing the anodes,

etc. Minimum clearances for proper operation are given above.

WARNING

In cold climates provide protection against freeze-up.

Installation of the water heater must be accomplished in such a

manner that if the tank or any connections should leak, the flow will

not cause damage to the structure.

For this reason, it is not advisable

to install the water heater in an attic or upper floor. When such

locations cannot be avoided, a suitable drain pan should be installed

under the water heater. Drain pans are available at your local

hardware store. Such a drain pan must have a minimum length

and width of at least 2 inches (51 mm) greater that the water heater

dimensions and must be piped to an adequate drain. The pan must

not restrict combustion air flow.

Water heater life depends upon water quality, water pressure and

the environment in which the water heater is installed. Water

heaters are sometimes installed in locations where leakage may

result in property damage, even with the use of a drain pan piped

to a drain. However, unanticipated damage can be reduced or

prevented by a leak detector or water shut-off device used in

conjunction with a piped drain pan. These devices are available

from some plumbing supply wholesalers and retailers, and detect

and react to leakage in various ways:

• Sensors mounted in the drain pan that trigger an alarm or turn off

the incoming water to the water heater when leakage is detected.

• Sensors mounted in the drain pan that turn off the water supply

to the entire home when water is detected in the drain pan.

• Water supply shut-off devices that activate based on the water

pressure differential between the cold water and hot water pipes

connected to the water heater.

• Devices that will turn off the gas supply to a gas water heater

while at the same time shutting off its water supply.

WARNING

DO NOT INSTALL THIS WATER HEATER DIRECTLY ON A

CARPETED FLOOR. A FIRE HAZARD MAY RESULT.

Instead

the water heater must be placed on a metal or wood panel

extending beyond the full width and depth by at least 3 inches

(76.2 mm) in any direction. If the heater is installed in a carpeted

alcove or closet, the entire floor shall be covered by the panel.

AIR REQUIREMENTS

In calculating the free area of a vent opening, the blocking effect

of screens, louvers and grills should be considered. Screens

shall not be of a mesh smaller than 1/4 inch square. If the free

area is not known, the current edition of National Fuel Gas Code

ANSI Z223.1 recommends using figures of 20-25 percent free

area for wood louvers or 60-75 percent for metal grills or louvers.

UNCONFINED SPACE

In buildings of conventional frame, brick or stone construction,

unconfined spaces may provide adequate air for combustion

and ventilation air for the power venter.

Содержание BTX-80

Страница 24: ...24...