3D Systems, Inc.

12

CONSUMABLES

The following items are consumed at varying rates during the SLS process:

•

Nitrogen

•

SLS Materials

•

Filters

•

Coolant

These items are described separately in the sections that follow .

•

Contact 3D Systems to purchase replacement SLS materials and filters.

•

See your nitrogen and coolant supplier to replenish stocks of these items .

Nitrogen Consumption

NOTE: Your site’s actual nitrogen consumption may vary from the nitrogen consumption estimate below .

One ProX 500 SLS 3D Printer system will consume approximately 140 cubic meters (4944 cubic feet) of nitrogen gas per week . This

estimate assumes seven days of continuous operation (24 hours/day) with seven purge cycles (one per day) .

NOTE: This volume estimate is for gaseous nitrogen—not liquid nitrogen . Be sure to ask your supplier for the proper

liquid-to-gas volume conversion ratio so you can properly size your tanks .

SLS Materials

The material listed below is available for purchase from 3D Systems . The material comes with its own 3D Systems Material Guide to

help you use it successfully .

•

DuraForm™ ProX Plastic

Refer to your

Material Guide

for further information .

Replaceable Filters Kit

The process station and chiller have customer-replaceable filters. 3D Systems recommends you keep a supply of these filters on hand

and replace them when necessary to ensure part quality and trouble-free operation . 3D Systems sells a kit containing a year’s supply of

filters.

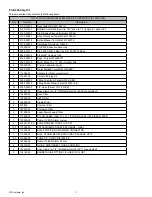

FILTER KIT (P/N 132562-00)

Laser Power Supply Filter

EPM Filter, Pleated

EPM filter, Charcoal, Pleated

Seal, HEPA Filter

Filter, HEPA

Filter, 2-stage, 5u (Sock)

Filter, Chiller, Air

Filter, Chiller, Coolant 10”

Electrical cabinet filters

CDA Filter on pressure regulator

NOTE: Filters are also replaced as necessary by your 3D Systems Field Service Representative during scheduled

preventive maintenance visits .