3D Systems, Inc.

5

ProX 500 SLS 3D Printer

Supplied by

: 3D Systems

Installed by

: 3D Systems

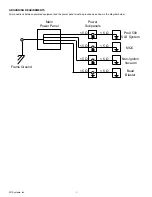

The printer requires a 3-phase, 208 VAC, 50/60 Hz, 10 kVA power source and a separate

Chiller

with its own single-phase power

source .

Ceiling drop lines for nitrogen supply and exhaust, electrical, and clean dry air (CDA) are recommended. The floor below the process

station must be flat and vibration-free. The room must be air-conditioned, with no vents directly above the machine. Clearance around

the process station is required so hinged access panels can be fully opened . See the

ProX 500 SLS 3D Printer Facility Requirements

Poster on page 33

for clearance requirements .

F

B

A

D

E

C

Stacklight:

Indicates the state of the system .

Print Chamber Area:

There are two doors in

front of the Print Chamber—the outer locking

door, and the inner print chamber door . The

parts are printed inside the Print Chamber .

E-Stop:

The Emergency Stop button is a

safety mechanism used to shut off the

machine in an emergency situation in which it

cannot be shut down in the usual manner .

User Interface (UI):

The user controls the

system using a touchscreen located on the

front panel .

LED Interface Lights and Controls:

There

are three LED lights which give the user visual

feedback regarding the system . The two

buttons allow the user to control the chamber

lights and enable the system . There are two

standard USB ports beneath them .

User and Service Access Panels:

There are

two types of panels on the sides and back of

the machine—user access and service

access . The user access panels are hinged

doors . The service access panels are lift-off

panels . A tool is required to open each panel .

A

B

C

D

E

F