3D Systems, Inc.

28

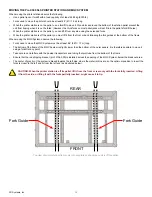

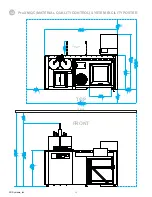

REAR

FRONT

Fork Guide

Fork Guide

Top view of printer station (frame only) showing fork position when unit is off the pallet.

MOVING THE ProX 500 SLS PRINTER STATION AND MQC SYSTEM

When moving the printer station observe the following:

•

Use a pallet jack or forklift with a load capacity of at least 2268 kg (5000 lb) .

•

Forks used to move the printer should be at least 48” (4ft / 1 .2m) long .

•

When the printer station is on the pallet, use a forklift to move it . Wood blocks around the bottom of the station pallet prevent the

unit from tipping when it is on the forks. (However, the thick forks on most pallet jacks will not fit into the pallet’s forklift holes.)

•

When the printer station is on the pallet, you can lift it from any side using the extended forks .

•

When the printer station is off the pallet, you must lift it from the front or back following the fork guides at the bottom of the frame .

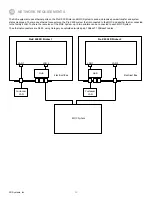

When moving the MQC System, observe the following .

•

Forks used to move the MQC System must be at least 66” (5 .5ft / 1 .7 m) long .

•

The bottom of the frame of the MQC System is slightly lower than the bottom of the outer panels . It is therefore possible to move it

using a forklift at any point .

•

Take care to not interfere with the powder transporters and tubing that protrude from the bottom of the frame .

•

Ensure that the red shipping bracket (p/n 121962-00) is installed across the opening of the MQC System, below the breakout area .

•

The center of gravity of the system is biased towards the left side, where the material bins are, so the optimum position to insert the

forks is closer to the left end or from the left end (as illustrated below) .

CAUTION: When the printer station is off its pallet, lift it from the front or rear only with the forks fully inserted . Lifting

it from the side, or lifting it with the forks partially inserted, might cause it to tip .