3D Systems, Inc.

29

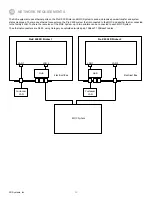

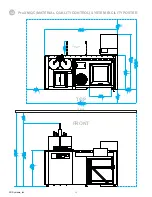

ProX 500 Printer and MQC System Placement

3D Systems Customer Support can advise you on placement of the equipment before installation . Also refer to the

ProX MQC (Material

Quality Control) System Facility Requirements Poster on page 32

and the

ProX 500 SLS 3D Printer Facility Requirements

Poster on page 33

. Be sure your facility meets the “Clearance Requirements” in the section

Room Requirements on page 16

so

there will be sufficient room for air circulation and service/operator access.

INSTALLATION VERIFICATIONS (PERFORMED BY 3D SYSTEMS)

Once all the ProX 500 3D SLS Printer System equipment is in place, your 3D Systems Field Service Representative will make the

required nitrogen, power, and coolant hook-ups and connections . The representative will also level the process station, then perform

the following verification procedures:

•

Complete machine module functional tests

•

Verify functionality of safety interlocks

•

Perform complete calibrations and tuning of components

•

Print an acceptance part to ensure system function

STORING THE SYSTEM

If it becomes necessary to store the system for an extended period of time, ensure that the storage area meets the

Temperature

,

Non-

condensing relative humidity

, and

Atmospheric corrosives

requirements listed in

Atmosphere Requirements on page 10

.

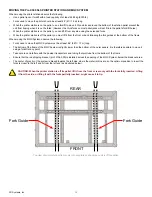

MQC System showing optimal insertion location for forks

5 feet

(153 cm)

Shipping brace

must be present

Most stable location

to insert forks