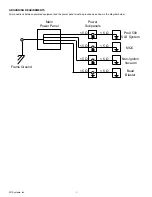

Air

Pressure

Air

Inlet

Nitrogen

Inlet

Nitrogen

Pressure

Coolant

Inlet

Coolant

Outlet

Pneumatics Panel

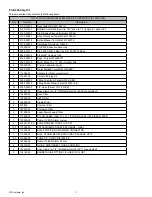

Nitrogen Options

N

2

CDA

min 16° C (60° F)

27° C (80° F)

max

Bulk nitrogen tank

▪ 99% pure nitrogen

▪ option for high nitrogen demand sites

Nitrogen dewars

▪ 99% pure nitrogen

▪ connect dewars with auto-switching

manifold(s) to ensure constant N

2

supply during build

Nitrogen generator

▪ 99% pure nitrogen

Coolant Hoses

▪ Included with 3D Systems-supplied chiller

▪ 1/2" barbed hose fitting

CDA (Clean Dry Air) Inlet

▪ 1/4" barbed hose fitting

Nitrogen Inlet

▪ 1/4" barbed hose fitting

1

2

3

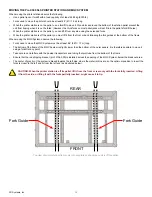

Air Conditioning

• required

•

d

o not install vent directly above process station

Room temperature

setpoint and stability

• set temperature between

18° C and 24° C (65° F and 75° F)

• temperature should be constant to

±

2° C (± 5° F)

Chiller power panel

• single phase

• separate from process

station power

Process station power panel

• Input: 208VAC, 50/60Hz, 3PH, 10kVA

• separate from chiller power

Process station power cable

•

drop down from ceiling

•

route through cable gland at top of

process station

•

connect to power distribution panel

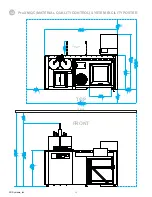

CEILING

Coolant

Access Panel

Pneumatic

Access Panel

Process Chamber

Door

Process Chamber

Panel

Rear Access

Panels

A/C

FRONT

TOP

CHILLER

CHILLER

CHILLER

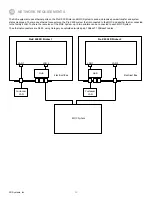

Room area oxygen monitor

• recommended

• customer supplied/installed

• safety interlock contact rating: 10 A

Transformer

(step-up or step-down)

• customer supplied and installed

• required if facility does not have:

208 VAC, 3-phase

50/60 Hz

10 kVA power

107.1 in 2721 mm

48.3 in 1226 mm

34.5 in 876 mm

21.7 in 550 mm

19.7 in 500 mm

144 in (12 ft )

3658 mm

Coolant Panel

ProX 500 SLS 3D PRINTER FACILITY REQUIREMENTS POSTER

13