UP Mini 3D Printer User Manual

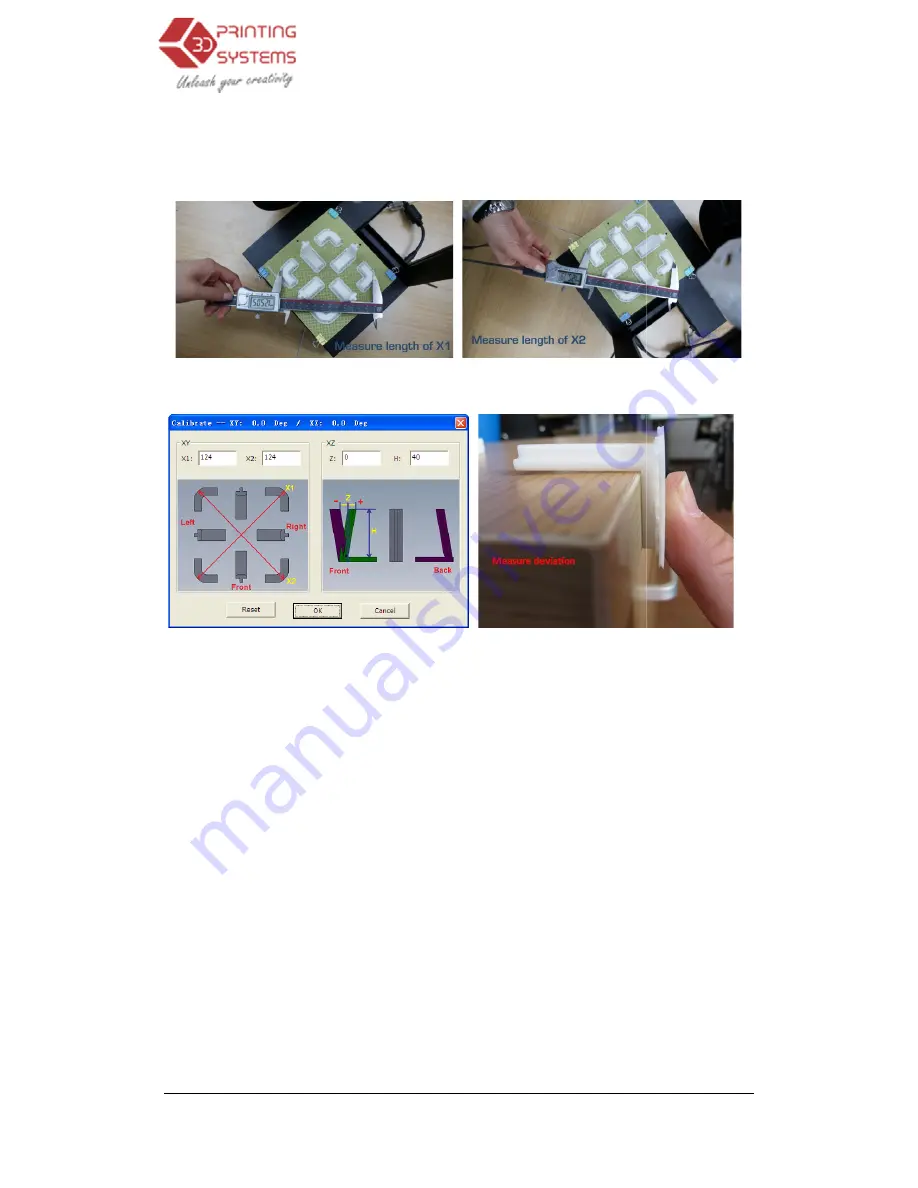

After the calibration model is printed, measure the X1 and X2 length

below.

Open the “Calibrate” box form the “3D Print” menu

Then enter the measured X1 and X2 values into the appropriate boxes.

IMPORTANT NOTE:

Before you enter any new calibration values, always click the “Reset”

button, otherwise the new values get added to the old ones. Before you enter any new values, the

bar at the very top of the screen should read: XY: 0.00 deg / XZ: 0.00 deg.

Next, take down the Front Centre ‘L’ shaped component

value into the Z box. If it deviates to the right side, the value

itive value. If the deviates to the left, the value

Finally, measure the height of Front

Enter the exact measured value into

Click “OK” to record all these values and exit the calibrat

6.3 Cleaning the outside of the

After a lot of printing, the nozzle may be covered with a layer of oxidized ABS

nozzle. When the printer is printing, this oxidized ABS may melt on the nozzle, and may create di

colored spots the model. To avoid this you need to regularly clean the nozzle.

3D Printer User Manual

After the calibration model is printed, measure the X1 and X2 length, as shown in the pictures

Open the “Calibrate” box form the “3D Print” menu.

enter the measured X1 and X2 values into the appropriate boxes.

Before you enter any new calibration values, always click the “Reset”

button, otherwise the new values get added to the old ones. Before you enter any new values, the

bar at the very top of the screen should read: XY: 0.00 deg / XZ: 0.00 deg.

Centre ‘L’ shaped component, and measure its deviation. Put the exact

value into the Z box. If it deviates to the right side, the value to be put into the Z box will be a po

itive value. If the deviates to the left, the value to put into the Z box will be a negative value.

Finally, measure the height of Front Center component, which should be 40mm if it is not scaled.

Enter the exact measured value into the “H” box of the “Calibrate dialogue box.

Click “OK” to record all these values and exit the calibration window.

outside of the nozzle

After a lot of printing, the nozzle may be covered with a layer of oxidized ABS on the outside of the

. When the printer is printing, this oxidized ABS may melt on the nozzle, and may create di

colored spots the model. To avoid this you need to regularly clean the nozzle.

44

, as shown in the pictures

Before you enter any new calibration values, always click the “Reset”

button, otherwise the new values get added to the old ones. Before you enter any new values, the

, and measure its deviation. Put the exact

he Z box will be a pos-

put into the Z box will be a negative value.

be 40mm if it is not scaled.

on the outside of the

. When the printer is printing, this oxidized ABS may melt on the nozzle, and may create dis-