8.2

Inspection intervals

Information

"

All maintenance and service work must be performed carefully and only by well-trained

personnel.

The guarantee conditions include keeping the inspection intervals!

Measures

Intervals

Remarks

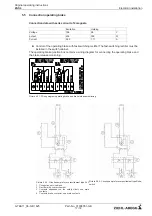

Check gears for unusual noises

every three months

Check oil level

every three months

Oil level according to marks on the

dipstick.

Check gearbox for leaks

every three months

First oil change after start-up

after 3 years

Further oil changes

after another 6 years

Clean bleeding screw

when changing the oil

Clean drive

when changing the oil

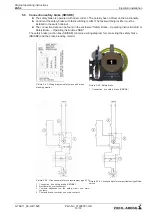

Operating brake

Check brake liners

with

speed control: annually

There maining thickness of the liner

must be at least 3 mm.

Operating brake

Check remaining stroke on brake

bleeding device

with

speed control: annually

Set remaining stroke.

Operating brake

Check electromagnets

every year

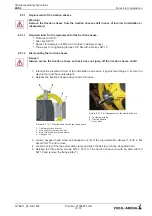

Safety brake

Check release gap

Every six months

Air gap nominal value

SB 0,3 +0,1 mm

SBE 0,35

±

0,1 mm

maximum air gap after wear 0.7 mm

Check the micro switch

Locking varnish must be undam-

aged.

every year

Check the distance between the set-

ting screw for the micro switch and

adjust if necessary.

Check the vicinity of the clutch for

unusual wear articles

every year

Plastic particles indicate inadmissi-

ble wear of the elastic plastic buffer

of the clutch.

Check rotation play of the clutch

after 5 years for the

fi

rst time

then annually

5 mm for a diameter of 360 mm at

the motor hand wheel are admissi-

ble.

Replacement of the elastic plastic

buffer

after 10 years

Check rotation play of the traction

sheave

every year

3 mm for a radius of 260 mm on the

driving disk are admissible.

Check the traction sheave if worn

out

every year

Check distance cable protection

every year

Visual inspection of the fastening

screws of the gearbox, drive, brakes

and traction sheave. Sealing varnish

must be undamaged.

every year

Note: The

fi

xing screws of the freaction sheave and the safety brake are marked by locking varnish.

Loosening of the screws is therefore visually recognisable. If a screw should turn, it must be

retightened with the prescribed torque, the old locking varnish removed and remarked.

Warning!

In case of changes or if the speci

fi

ed values are not observed, see chapter "Faults, causes and

remedy".

2ULJLQDORSHUDWLQJLQVWUXFWLRQV

ZAS0

Service & maintenance

A-TBA11_06-GB

Part.-No. 01008051-GB

25/72

Summary of Contents for ZAS0

Page 1: ...6 OHYDWRU PDFKLQH ZLWK JHDU 2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV 6WRUH IRU IXWXUH XVH 7 B 3DUW 1R 8...

Page 38: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 38 72...

Page 40: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 40 72...

Page 41: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 41 72...

Page 42: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 42 72...

Page 43: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 43 72...

Page 45: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 45 72...

Page 47: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 47 72...

Page 48: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 48 72...

Page 49: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 49 72...

Page 50: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 50 72...

Page 51: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 51 72...

Page 53: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 53 72...

Page 54: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 54 72...

Page 55: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 55 72...

Page 56: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 56 72...

Page 58: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 58 72...

Page 60: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 60 72...

Page 61: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 61 72...

Page 62: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 62 72...

Page 63: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 63 72...

Page 65: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 65 72...

Page 66: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 66 72...

Page 68: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 68 72...

Page 69: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 69 72...

Page 70: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 70 72...

Page 71: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 71 72...