5 Electrical installation

5.1

Safety precautions

Mounting, electrical connection and commissioning are only to be performed by trained service

personnel. Adhere to all machinery-related requirements and speci

fi

cations supplied by the system

manufacturer or machine builder.

5.2

EMC directive

The adherence to the EMC Directive 2004/108/EC only pertains to this product if controllers tested

and recommended by ZIEHL-ABEGG SE are used, which have been installed in accordance with the

corresponding controller description and in line with the EMC. If the product is integrated unprofes-

sionally into a system or complemented by and operated with components (e. g. regulators and

controllers) which have not been recommended, the operator of the complete system alone shall be

responsible for adhering to the EMC Directive 2004/108/EC.

5.3

Motor connection

CAUTION!

"

The drive must not be connected to the mains supply without a controller!

"

The motor is permitted to be used at frequency inverters with a maximum DC-link voltage

of < 750 V DC!

"

A screened motor cable has to be used. The screen has to be connected on both ends.

The maximum motor cable length is 25 m.

"

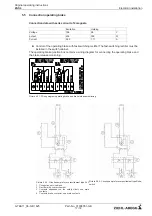

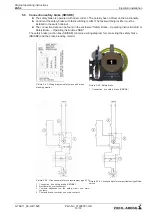

There is a wiring diagram in the motor junction box which shows how to connect the motor and

the PTC thermistor.

"

The motor is protected by PTC-resistors. The connection has to be made through a PTC resistor

controller unit!

"

Make sure that the motor contactors are switched load-free on the control side. The contactor

contacts could be damaged when switching under load, especially at rpm 0.

Therefore the

controller enable should always be switched off before or together with the main con-

tactors.

Danger!

"

This connection must be made by a specialist according to the pertinent safety regulations.

"

The pertinent installation and operating regulations as well as the normal national and

international regulations must be observed.

"

See the data on the rating plate!

"

See the circuit!

Information

"

Adapt the power cable cross sections to the reference current value.

"

Provide strain relief for the connecting leads.

"

Always connect the protective earth according to DIN VDE 0100 to the marked PE terminal.

"

Use the original seal for connecting the junction box.

"

Seal unnecessary openings dust and water tight.

CAUTION!

Caution!

"

No voltage greater than 2.5 V may be applied to the PTC thermistor!

"

Damp windings can lead to creep currents, sparkovers and disruptive discharges. The insulation

resistance of the stator winding must be at least 1.5 megaohms in 220 V - 1000 V motors,

measured at a winding temperature of 20

°

C. The winding must be dried at lower values.

2ULJLQDORSHUDWLQJLQVWUXFWLRQV

ZAS0

Electrical installation

A-TBA11_06-GB

Part.-No. 01008051-GB

15/72

Summary of Contents for ZAS0

Page 1: ...6 OHYDWRU PDFKLQH ZLWK JHDU 2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV 6WRUH IRU IXWXUH XVH 7 B 3DUW 1R 8...

Page 38: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 38 72...

Page 40: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 40 72...

Page 41: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 41 72...

Page 42: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 42 72...

Page 43: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 43 72...

Page 45: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 45 72...

Page 47: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 47 72...

Page 48: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 48 72...

Page 49: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 49 72...

Page 50: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 50 72...

Page 51: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 51 72...

Page 53: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 53 72...

Page 54: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 54 72...

Page 55: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 55 72...

Page 56: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 56 72...

Page 58: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 58 72...

Page 60: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 60 72...

Page 61: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 61 72...

Page 62: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 62 72...

Page 63: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 63 72...

Page 65: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 65 72...

Page 66: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 66 72...

Page 68: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 68 72...

Page 69: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 69 72...

Page 70: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 70 72...

Page 71: ...2ULJLQDO RSHUDWLQJ LQVWUXFWLRQV ZAS0 Enclosure A TBA11_06 GB Part No 01008051 GB 71 72...