MAINTENANCE

CLEAN OR REPLACE AIR FILTERS REGULARLY

The intervals at which fi lters require replacement

depend on local conditions.

Under normal conditions, the room air fi lter requires

replacement every six to eight weeks. In a new build-

ing, loose dirt tracked in from the outside may shorten

this period.

To ensure proper maintenance of the fi lters, it is best

to follow an organized maintenance procedure.

MONTHLY CHECK LIST

• Inspect the unit air fi lters. Clean or replace as

required.

• Inspect the drainpan to be sure it is clean to permit

the fl ow of condensate through the drain lines.

• Inspect the fan belt for wear and alignment. Replace

or adjust as required.

YEARLY CHECK LIST

• Inspect the blower coil unit casing for corrosion and

loose fasteners.

• Inspect the blower wheel and housing. Clean if

necessary.

• Check the motor pulley and blower pulley for

alignment and tighten their set screws. Adjust belt

tension if necesssary.

• Inspect all coil connections for leaks Inspect the coil

fi ns for excessive dirt or damage. clean or repair if

required.

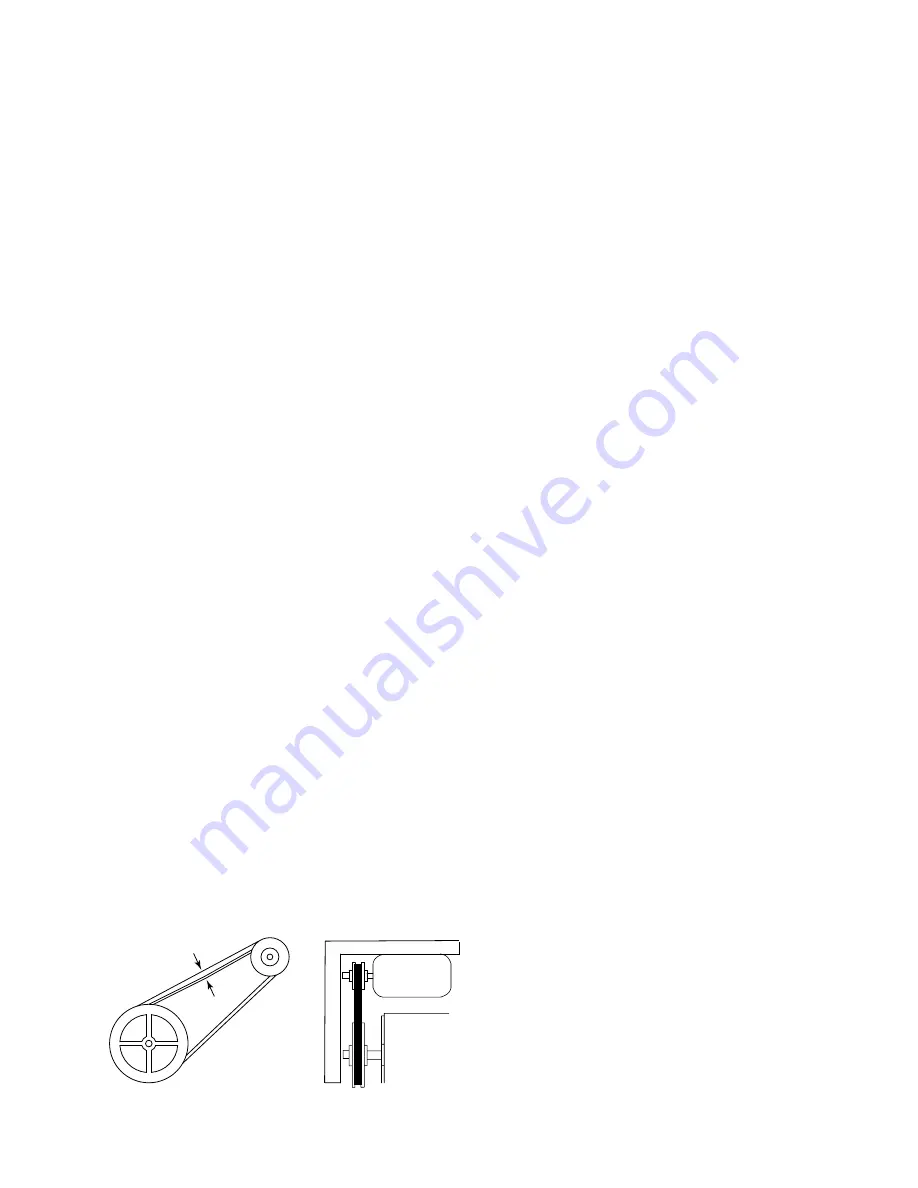

PULLEY ALIGNMENT AND BELT TENSION

Belt tension and pulley alignment should be checked.

Belt tension is adjusted by means of the motor tailpiece

adjusting bolt or the position of the motor on the base

style motor mount. A defl ection of about 3/4” to 1”

per foot of span should be obtained by pressing the

belt fi rmly

(see Figure 6)

The adjusting bolt should

be locked in position after the adjustment is made.

Alignment of pulley grooves is made by locating the

motor pulley on the motor shaft or by moving the

entire motor along the motor mounting bracket. For

blower speed adjustment, refer to that section.

BLOWER

Inspect the bearings for wear. They are ball bearing,

self-aligning and grease packed. Replace if required.

Inspect the thrust collars for end play and alignment

of wheel. Check the blades for accumulations of dirt

and clean in order to avoid imbalance and vibration.

Check mounting brackets, base bolts and isolation

material.

MOTOR

Check motor connections to ensure that they are secure

and made in accordance with the wiring diagram.

The blower motor should be cleaned annually and if it

has oiling ports, it should be oiled with a good grade

of SAE 20 oil. Normally a few drops of oil in each

bearing is suffi cient.

COIL

Any dust or other contaminants, which accumulate on

the heat transfer surfaces, interferes with the airfl ow

and impairs heat transfer. The coil must be kept clean

by any of the following methods:

• Cleaning with low-pressure compressed air.

• Flushing or rinsing with water (a detergent is

advisable for greasy surfaces).

• If strainers are installed in the valve packages,

clean the strainers once a year per manufactures

directions.

FILTER

The air fi lter should be cleaned or replaced as often as

necessary to prevent restriction of air fl ow. Always

replace the fi lter with the same type as originally

furnished.

To clean permanent fi lters, remove the fi lter and wash

in water to remove the old fi lter oil. Rinse in clean, hot

water and allow to dry. Recoat both sides of the fi lter

with RP fi lter coat, or an equivalent. Allow to drain

and dry thoroughly before reinstalling the fi lter.

DRAIN PIPING

The drain should always be connected or piped to an

acceptable disposal point sloped away from the unit.

Check the drain line for restrictions or blockage before

summer operation and monthly during the cooling

season.

DRAIN PAN

The drain pan should be clean to allow proper conden-

sate fl ow. Remove any accumulation of residue from

the drain pan and inspect for rust and leaks.

3/4" to 1" PER

FOOT OF SPAN

PULLEY ALIGNMENT

FIG 6 - PULLEY ALIGNMENT AND BELT

ADJUSTMENT

7

YORK INTERNATIONAL

FORM 115.22-NOM5 (704)