INSTALLATION

RECEIVING .......................................................................................................................................................................... 2

STORAGE ............................................................................................................................................................................ 2

SHIPPING WEIGHTS ........................................................................................................................................................... 2

PREPARING UNIT .......................................................................................................................................................... 2 & 3

CEILING INSTALLATION................................................................................................................................................ 2 & 3

WIRING ...................................................................................................................................................................... 3 & 4

DUCTWORK ......................................................................................................................................................................... 4

PIPING ...................................................................................................................................................................... 4 & 5

DIMENSIONS ................................................................................................................................................................. 5 & 6

MAINTENANCE

........................................................................................................................................................................ 7

STARTUP

CHECKLIST .......................................................................................................................................................................... 8

TABLE OF CONTENTS

RECEIVING

Unpack the unit as close to the installation site as

practical, minimizing any possible handling damage.

When unpacking the unit, remove all securing hard-

ware straps, wires, blocks, padding, and protective

tape. Note and follow instructions on any special

packing or caution notices that may be attached to the

unit.

See Table 1 for shipping weights.

STORAGE

If the Unit is not to be immediately installed, store

it in a dry location with the motor protected against

moisture, dust, corrosion and physical damage.

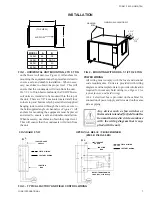

UNIT ELEVATION

Mounting holes are provided by York for the conve-

nience of the installer

(see Figure 2)

. Threaded Rod

Hangers prove to be most desirable and effective for

mounting the unit. Rod Hangers and mounting hard-

ware are to be provided by the contractor.

Vibration isolators, if required, should be installed.

PREPARE CEILING FOR MOUNTING

Depending upon building construction, provisions

for mounting the unit must be made by the contractor

according to architects; drawings.

Before mounting unit remove red

headed shipping bolts and metal bush-

ing at blower base and blower outlet.

In addition remove, if present, the wire

tie securing motor to blower rail before

operating.

Suffi cient clearance must be provided on the side of

the blower coil to allow access to electrical controls

and to service the motor blower assembly.

Standard unit confi guration is right hand looking with

the direction of airfl ow.

It is important to ensure that the blower coil unit is

securely mounted and the structure is suffi cient to

support the weight of the equipment. On 2 to 5 ton

horizontal units, two (2) mounting rails are supplied

TABLE 1 - SHIPPING WEIGHTS

HORIZONTAL AIR HANDLER

SHIPPING WT. (LBS)

UNIT DESCRIPTION

UNIT MODEL

SHIPPING WT. (LBS)

UNIT MODEL

W/4 ROW COIL

W/6 ROW

COIL

2 TON HORIZ

24YSHX

185

24YSHW

185

205

3 TON HORIZ

36YSHX

215

36YSHW

205

225

4 TON HORIZ

48YSHX

250

48YSHW

240

265

5 TON HORIZ

60YSHX

320

60YSHW

290

310

7-1/2 TON HORIZ

90YSHX

400

90YSHW

450

475

10 TON HORIZ

120YSHX

525

120YSHW

490

535

15 TON HORIZ

180YSHX

775

180YSHW

670

710

20 TON HORIZ

240YSHX

835

240YSHW

835

880

INSTALLATION

YORK INTERNATIONAL

2

FORM 115.22-NOM5 (704)