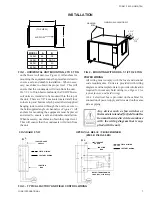

FIG 1 - HORIZONTAL UNIT MOUNTING, 2 TO 5 TON

INSTALLATION

A

B

(TOP VIEW)

AIR FLOW

MODEL

A

B

24SH

35

29

36SH

35

38-1/2

48SH

37

40

60SH

40

47

on the blower coil unit.

(see Figure 1)

All anchors for

mounting the equipment must be placed and sized to

ensure a safe and durable installation. When neces-

sary, use shims to obtain the proper level. This will

ensure that the condensate will drain from the unit.

On 7-1/2 to 20 ton horizontal units, the YSHW blower

coil units are intended to be mounted thru the top of

the unit. There are 7/8” knockouts located at all four

corners top and bottom which permits fi eld supplied

hanging rods to extend through the unit to secure to

the fi eld supplied angle or channel

(see Figure 2)

All

anchors for mounting the equipment must be placed

and sized to ensure a safe and durable installation.

When necessary, use shims to obtain the proper level.

This will ensure that the condensate will drain from

the unit.

POWER WIRING

All wiring must comply with the local and national

code requirements. Units are provided with wiring

diagrams and nameplate data to provide information

required for necessary fi eld wiring

(see Figure 3 for

typical factory and fi eld wiring).

A 4 x 4 electrical box is provided on the cabinet for

connection of power supply and is located on the same

side as piping.

Any devices such as fan switches or

thermostats intended for fi eld installa-

tion must be wired in strict accordance

with the wiring diagram that is sup-

plied with the unit.

HANGING

RODS

3-1/2"

TYP

3-1/2"

TYP

YSHW/YSHX 90-240 MODELS

FIG 2 - MOUNTING WITH RODS, 7-1/2 TO 20 TON

120V-1PH-60HZ

SUPPLY

JUNCTION

BOX

OPTIONAL RELAY / TRANSFORMER

(FIELD INSTALLED)

FIELD WIRING

FACTORY WIRING

120V-1PH-60HZ

SUPPLY

JUNCTION

BOX

RELAY / TRANSFORMER

3/4 HP Max. Load Rating

N L

STANDARD UNIT

N L

FIELD WIRING

FACTORY WIRING

FIG 3 - TYPICAL FACTORY AND FIELD CONTROL WIRING

3

YORK INTERNATIONAL

FORM 115.22-NOM5 (704)