INSTALLATION

• Never insulate the heads or motorized portion of

control valves. Damage can occur in the form

of excessive heat build up and interference to the

operation and moving parts may result.

• All piping fabricated in the fi eld should be installed

with consideration of additional space for any

electrical routing that may be required.

• Connect all piping per accepted industry standards

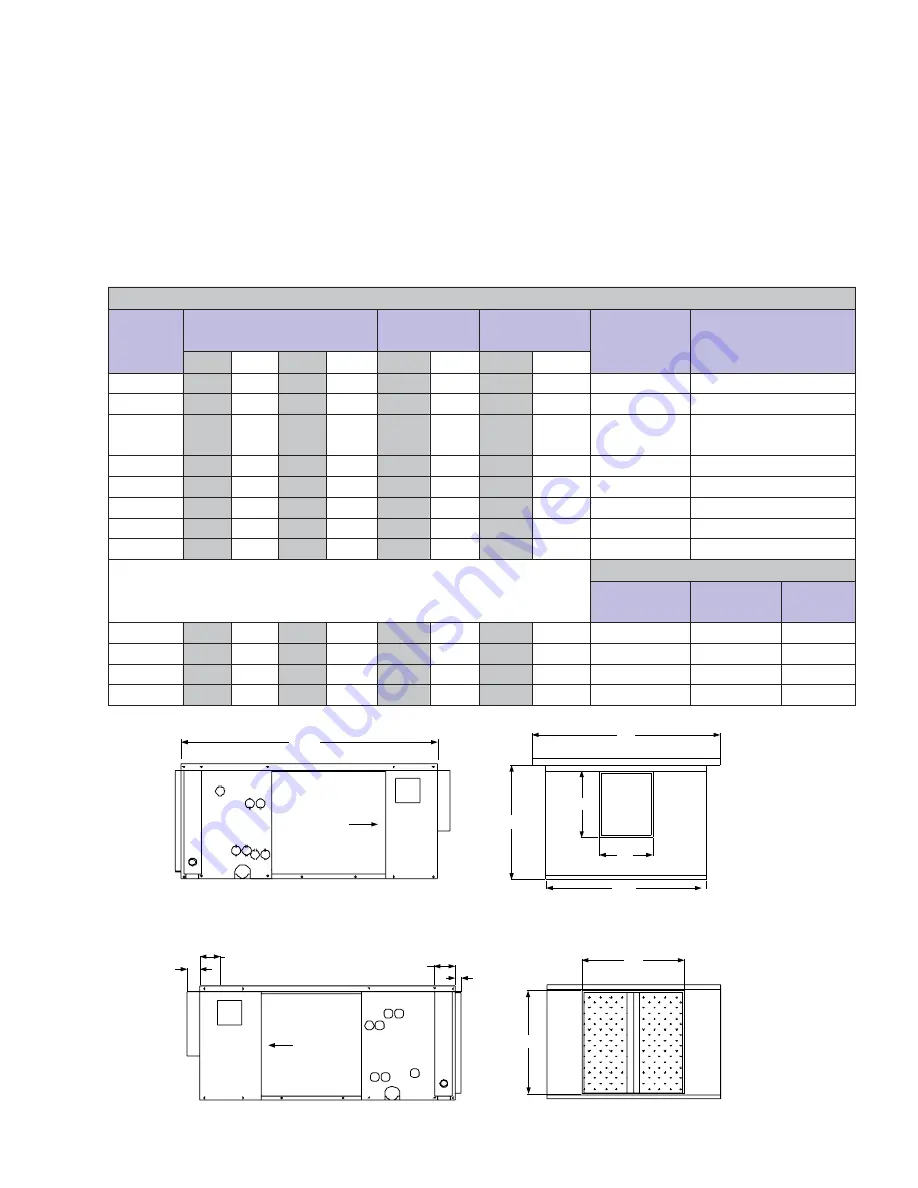

GENERAL DIMENSIONS

MODEL

UNIT CABINET

BLOWER

OUTLET

RETURN DUCT

CONNECTION

FILTER SIZE

MANIFOLD

CONNECTION

AA

BB

CC

DD

EE

FF

GG

HH

24YSHW4

37

32-1/2

27

18-7/8

8-3/4

10-7/8

18

16-1/4

16 X 25

7/8 ODS.

36YSHW4

37

42

36-1/2

18-7/8

12-1/4

10-7/8

27-1/2

16-1/4

16 X 16 (2)

7/8 ODS.

48YSHW4

39

43-1/2

38

22-7/8

13-5/8

11-7/8

29

20-1/4

16 X 20 (2)

7/8 ODS.

60YSHW4

42

50-1/2

45

22-7/8

16

13-7/8

36

20-1/4

20 X 20 (2)

1-1/8 ODS.

24YSHW6

37

32-1/2

27

18-7/8

8-3/4

10-7/8

18

16-1/4

16 X 25

7/8 ODS.

36YSHW6

37

42

36-1/2

18-7/8

12-1/4

10-7/8

27-1/2

16-1/4

16 X 16 (3)

7/8 ODS.

48YSHW6

39

43-1/2

38

22-7/8

13-5/8

11-7/8

29

20-1/4

16 X 20 (3)

7/8 ODS.

60YSHW6

42

50-1/2

45

22-7/8

16

13-7/8

36

20-1/4

20 X 20 (2)

1-1/8 ODS.

4 ROW COIL

FILTER SIZE

LIQUID

(SWEAT)

SUCTION

(SWEAT)

24YSHX4

37

31

27

18-7/8

8-3/4

10-7/8

18

16-1/4

16 X 25

3/8 ODS.

3/4 ODS.

36YSHX4

37

40-1/2

36-1/2

18-7/8

12-1/4

10-7/8

27-1/2

16-1/4

16 X 16 (2)

3/8 ODS.

3/4 ODS.

48YSHX4

39

42

38

22-7/8

13-5/8

11-7/8

29

20-1/4

16 X 20 (2)

1/2 ODS.

7/8 ODS.

60YSHX4

42

49

45

22-7/8

16

13-7/8

36

20-1/4

20 X 20 (2)

1/2 ODS.

7/8 ODS.

FIG 4 - DIMENSIONS FOR 2 - 5 TON UNITS

DD

EE

FF

CC

BB

2.00

3.50

3.50

1.00

AIR FLOW

HH

GG

AIR FLOW

AA

Note: The 3.50” dimension locates the 7/8” knock outs for mounting rods.

and observe all regulations governing installation of

piping systems. When all connections are complete,

the system must be pressure tested. Repair any

solder joint leaks and gently tighten any leaking

valve packing nuts and piping accessories as

required. Hydronic systems are not designed to

hold pressurized air and should only be tested with

water.

5

YORK INTERNATIONAL

FORM 115.22-NOM5 (704)