INSTALLATION

F

or piping guidelines, see the most recent issue of

Form 050.40-ES3.

Condensate drain lines must be installed with adequate

slope away from the unit to assure positive drainage.

Since the drain pan is located on the suction side of

the blower, a negative pressure exists at the drain pan

and a minimum trap of 1-1/2 inches must be provided

in the drain line to assure proper drainage. Drain pan

has positive slope to the nipple, which is located on

the coil connection side of the unit.

PIPING INSULATION

After the system has been proven leak free, all lines

and valve control packages must be insulated to pre-

vent condensate drippage or insulated as specifi ed on

the building plans.

Many valve packages will not physi-

cally allow all components to fi t over

an auxiliary drain pan. It is the in-

stallers responsibility to capture all

condensation or insulate the piping

to prevent condensation.

GENERAL PIPING PRECAUTIONS

• Clean all fi eld piping prior to connection to remove

all debris.

• Use wet cotton rags to cool valve bodies, if present,

when soldering.

• Open all valves (mid-way for hand valves, manually

open on motorized valves) prior to soldering.

• When soldering to bronze or brass, heat the piping

while in the socket/cup and begin introducing the

solder when the fl ux boils rapidly. Avoid direct

fl ame into the solder joint.

• Heat can only be applied to the cup of the valve body

for a minimal time before damage occurs (even with

the use of wet rags.

• Avoid rapid quenching of solder joints as this will

produce joints of inferior quality.

• The coil header or valve package will not support

the weight of the connecting pipes. All pipes,

which are connected to the unit, must be completely

supported prior to connection to the unit.

• Provisions must be made for expansion and

contraction of piping systems. All horizontal and

vertical risers, including runouts, must be able to

withstand signifi cant movement with temperature

changes. Failure to do so will result in damage and

failure of piping, fi ttings and valves throughout the

building.

CONTROL WIRING

These blower coil units can be provided with an

optional class 2 relay/transformer for 24-volt control

circuits (3/4 HP maximum load rating). Should any

add-on equipment also have a Class 2 transformer fur-

nished, care must be taken to prevent interconnecting

outputs of the two transformers by using a thermostat

with isolating contacts.

DRAIN PIPING

Unit models incorporate a positive slope drain pan

with a ¾” NPT nipple that exits the unit on the side

of the coil header connections. All units need to be

leveled to insure positive slope toward the condensate

drain nipple.

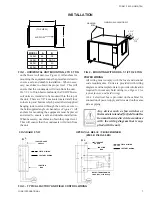

AIR DISTRIBUTION DUCT WORK

All duct work must be installed in accordance with

national fi re protection Association codes 90A and

90B. Ducts should be adequately insulated to prevent

condensation during the cooling cycle and to minimize

heat loss during the heating cycle. All return air must

be fi ltered to prevent dirt buildup on the coil surface.

In many cases, it is acceptable to use ducting of the

same size as the blower coil return air connection.

However, unique arrangements or long duct runs, must

be confi rmed by a local professional.

PIPING

YSHW units employ a hydronic coil designed for use

with either hot or chilled water. Each coil has a 1/4

inch bleed line.

All piping must be adequately sized to meet the design

water fl ow requirements as specifi ed for the specifi c

installation. Piping must be installed in accordance

with all applicable codes. All chilled water piping

must be insulated to prevent condensation.

YSHX units have a DX coil for use with cooling or

heat pump condensing units (2-5 Ton only).

When connecting piping or valve kits

to blower coil units, do not bend or

reposition the coil header tubing for

alignment purposes. This could cause

a tubing fracture resulting in a water

leak when water pressure is applied to

the system. All units have knockouts

on both sides for either right or left

side coil stubouts.

The piping connections on the equipment

(see Figure

4 & 5)

are not necessarily indicative of the proper

supply and return line sizes. All units have knockouts

on both sides for either right or left side coil stubouts.

YORK INTERNATIONAL

4

FORM 115.22-NOM5 (704)