SECTION 2 - PRODUCT DESCRIPTION

FORM 155.32-ICOM2.EN.UL

ISSUE DATE:1/10/2018

18

JOHNSON CONTROLS

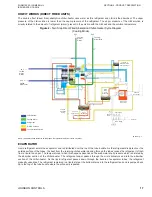

ABSORBER

Concentrated LiBr solution enters the absorber section of the chiller-heater and is sprayed

over the absorber tube bundle. Because the vapor pressure of the concentrated solution is

very low, the refrigerant (water) vapor from the evaporator flows into the absorber and is

absorbed into the LiBr solution. This mass transfer process lowers the concentration of the

LiBr solution as the refrigerant (water) is absorbed into the solution. This dilution process

generates heat and, if not cooled, will eventually stop as the solution temperature will rise

with a corresponding rise in vapor pressure. This would be similar to closing the vanes or

slowing down a centrifugal compressor on a centrifugal chiller where the load was

constant. The water flowing inside the absorber tube bundle comes from the cooling tower

and serves to cool the LiBr solution as it flows down over the tube bundle. This allows the

absorption process to continue and the solution becomes increasingly diluted as it absorbs

more refrigerant vapors. When the LiBr solution reaches the bottom of the absorber

section, it goes into the suction of the solution pump. The liquid is then pumped to the

generators.

The following section describes the unique 2-step evaporator-absorber design of the

YHAU-CGN/H direct fired absorption chiller-heater.

TWO-STEP EVAPORATOR – ABSORBER

The evaporator, as well as the absorber, is split into two sections. This design, similar to a

series-counter-flow chiller-heater arrangement along with the parallel flow cycle, enables

lower LiBr solution concentrations. This reduces pressure, the potential for corrosion, the

risk of crystallization, and improves efficiency in conjunction with other advanced

components described later in this section.

The two evaporators are in series with respect to the chilled water flow through the tubes.

In other words, the chilled water flows through the lower evaporator tubes first and then to

the upper evaporator tubes. Each evaporator operates at a slightly different temperature

and pressure. The refrigerant in the lower evaporator boils at a slightly higher temperature

than in the upper evaporator, consequently cooling the chilled water in two steps.

The two absorber sections are split as well, with the strong solution first entering the top of

the uppermost absorber and flowing down through the top absorber bundle. It then flows

into the top of the lower absorber section. The strong solution entering the upper absorber

takes advantage of its lower vapor pressure allowing the upper evaporator to operate at a

lower pressure and temperature.

When the LiBr solution enters the lower absorber section it is somewhat diluted from the

refrigerant vapor that boiled off in the upper evaporator. At this lower concentration the

solution vapor pressure would normally not be sufficient to provide an evaporator pressure

low enough to satisfy the leaving chilled water design. However, the lower evaporator is the

first step of the chilled water cooling cycle, and the dilute solution’s vapor pressure is

adequate to maintain the required temperature and pressure in the lower evaporator.

The cooling tower water enters the lower absorber section first, keeping the vapor pressure

of the weaker solution as low as possible.

Both the refrigerant (water) and LiBr dispersion system are gravity fed and constructed of

stainless steel.

LD19880_a3

LG4

Evaporator

(Upper)

Absorber

(Upper)

Absorber

(Lower)

Evaporator

(Lower)

Concentrated

LiBr

Refrigerant

Chilled

Water

Out

Chilled

Water

In