SECTION 1 - GENERAL CHILLER-HEATER INFORMATION AND SAFETY

FORM 155.32-ICOM2.EN.UL

ISSUE DATE:1/10/2018

12

JOHNSON CONTROLS

The unit warranty will be void if any modification to the unit is carried out without prior

written approval from Johnson Controls. For warranty purposes, the following conditions

must be satisfied:

• The initial start of the unit must be carried out by trained personnel from an authorized

Johnson Controls Field Service Office.

• Only genuine Johnson Controls approved spare parts, oils, solutions, chemicals, and

refrigerants must be used.

• All of the scheduled maintenance operations detailed in this manual must be per-

formed at the specified times by suitably trained and qualified personnel.

Failure to satisfy any of these conditions will automatically void the warranty. Refer to

Limited Warranty (Form 50.05-NM2)

for complete details.

QUALITY ASSURANCE

Units comply with the following directives:

• GB/T 18431-2014 Direct Fired Lithium Bromide Absorption Water Chiller-Heater

•

UL 1995-2015 Standard for Safety Heating and Cooling Equipment

• UL 508A Industrial Control panel

• NFPA70 National Electrical Code

•

NFPA79 Electrical Standard for Industrial Machinery

The unit must be grounded. No installation or maintenance work should be attempted on

the electrical equipment without first switching the power OFF, then isolating and locking-

off the power supply. Servicing and maintenance on live equipment must not be attempted.

No attempt should be made to gain access to the control panel or electrical enclosures

during normal operation of the unit.

Components may also have sharp edges. Reasonable care should be taken when working

in contact with any components to avoid risk of abrasions and lacerations.

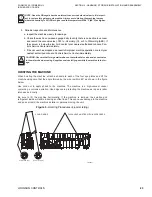

EMERGENCY SHUTDOWN

In case of emergency, the control panel is fitted with an incoming supply circuit breaker with

a red handle. Turn the handle counter clockwise to shut down the chiller.

HIGH TEMPERATURE AND PRESSURE CLEANING

High temperature and pressure cleaning methods (such as steam cleaning) should not be

used on any part of the pressure system as this may cause operation of the pressure relief

device(s). Detergents and solvents, which may cause corrosion should also be avoided.

LD27461

Turn counter clockwise