38

YORK INTERNATIONAL

GENERAL

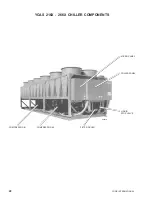

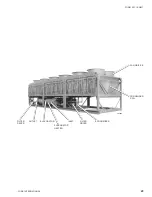

GENERAL DESCRIPTION

The Air Cooled Screw Chiller utilizes many components

which are the same or nearly the same as a standard

reciprocating chiller of a similar size. This includes

modular frame rails, condenser, fans and evaporator.

The chiller consists of two screw compressors in two

separate refrigerant circuits, a single shell and tube DX

evaporator, economizers, an air cooled condenser, and

expansion valves. Standard efficiency chillers have 4

fans per refrigerant system and operate in pairs. High

efficiency chillers have 6 fans per refrigerant system and

operate in groups of 3 (trio).

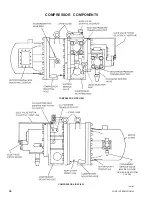

COMPRESSOR

The Frick semi-hermetic rotary twin-screw compressor

utilizes a twin screw design with a single slide valve for

capacity control. The compressor is a positive

displacement type characterized by two helically grooved

rotors. The 60 Hz motor operating at 3570 RPM drives a

geared speed increaser to drive the male rotor between

4125 - 7600 RPM. The female rotor is driven by the male

rotor on a light film of oil. Compressors with gear sets

running at higher speeds will have greater capacity.

Refrigerant gas is injected into the void created by the un-

meshing of the 5 lobed male and 7 lobed female rotor.

Further meshing of the rotors closes the rotor threads to

the suction port and progressively compresses the gas in

an axial direction toward the discharge port. The gas is

compressed in volume and increased in pressure before

exiting at a designed volume at the discharge end of the

rotor casing. Since the intake and discharge cycles

overlap, a resulting smooth continuous flow of gas is

maintained.

Contact between the male and female rotor is primarily

rolling on a contact band on each of the rotors pitch circle.

This results in virtually no rotor wear and increased

reliability, a trademark of the screw compressor.

The compressor incorporates a complete anti-friction

bearing design for reduced power input and increased

reliability. Four separated, cylindrical, roller bearings

handle radial loads. Angular-contact ball bearings handle

axial loads. Together they maintain accurate rotor

positioning at all pressure ratios, thereby minimizing

leakage and maintaining efficiency. A check valve is

installed in the compressor discharge housing to prevent

compressor rotor backspin due to system refrigerant

pressure gradients during shutdown.

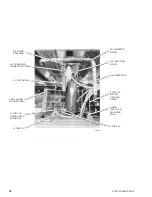

Motor cooling is accomplished by injecting intermediate

pressure wet vapor into the motor which allows for better

efficiency than the traditional use of lower pressure

suction gas which requires more energy to raise to

discharge pressure. On demand high pressure liquid

injection provides additional motor cooling when internal

oil temperatures ruse. Addtional motor cooling required

during low load operation is supplied by a 5 ton TXV. A

drain line drains excess liquid from the motor housing and

feeds it into the gear cavity.

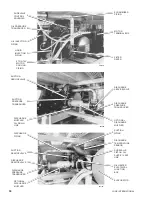

The compressor is lubricated by removing oil from the

refrigerant using an external oil separator. The pressur-

ized oil is then piped back to the compressor for

lubrication. The compressor design working pressure is

144 PSIG on the discharge side. Each chiller receives a

300 PSIG low side and 450 PSIG high side factory test.

A 500 watt (115-1-60) immersion heater is located in the

compressor. The heater is temperature activated to

prevent refrigerant condensation.

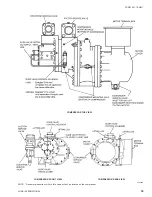

EVAPORATOR

The system uses a Shell and Tube type Direct Expansion

Evaporator. Each of the two refrigerant circuits consists

of 4 passes with the chilled liquid circulating back and

forth across the tubes from one end to the other. The

design working pressure of the cooler shell on the liquid

side is 150 PSIG, and 235 PSIG for the tube (refrigerant

side). The cooler is equipped with a heater to provide

freeze protection to -20°F (-28.8°C).

Water connections are grooved to accept victaulic

couplings.

FIG. 4 – COMPRESSOR ROTORS

LD01095

ACTUAL

ROTOR

ASSEMBLY

27936A(D)

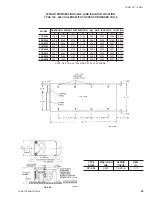

Summary of Contents for Millennium YCAS 216X

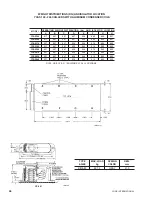

Page 11: ...FORM 201 10 NM1 11 YORK INTERNATIONAL YCAS 140 246 DIMENSIONS English LD01444 LD01446...

Page 13: ...FORM 201 10 NM1 13 YORK INTERNATIONAL YCAS 140 246 DIMENSIONS SI LD01440 LD01442...

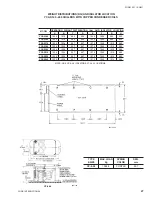

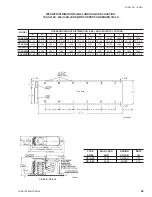

Page 15: ...FORM 201 10 NM1 15 YORK INTERNATIONAL YCAS 216X 266X DIMENSIONS English LD01454 LD01454...

Page 17: ...FORM 201 10 NM1 17 YORK INTERNATIONAL YCAS 216X 266X DIMENSIONS SI LD01450 LD01448...

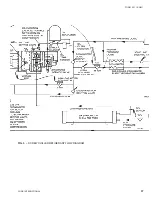

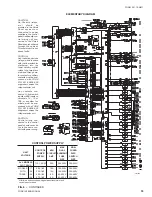

Page 33: ...FORM 201 10 NM1 33 YORK INTERNATIONAL 28514A FILTER DRYER LIQUID STOP VALVE...

Page 37: ...FORM 201 10 NM1 37 YORK INTERNATIONAL LD01285 FIG 3 SCREW CHILLER REFIGERANT FLOW DIAGRAM...

Page 59: ...FORM 201 10 NM1 59 YORK INTERNATIONAL FIG 11 CONTINUED LD01465 D...

Page 61: ...FORM 201 10 NM1 61 YORK INTERNATIONAL FIG 12 CONTINUED LD01458 D...

Page 69: ...FORM 201 10 NM1 69 YORK INTERNATIONAL FIG 16 CONTINUED LD01206 D...

Page 71: ...FORM 201 10 NM1 71 YORK INTERNATIONAL FIG 17 CONTINUED LD01202 D...