9. Cooling water system

163

9.3.3 Fresh water pump disassembly

(1) Do not disassemble the fresh water pump. It is difficult to disassemble and, once

disassembled, even more difficult to reassemble. Replace the pump as an assembly in

the event of trouble.

(2) When removing the fresh water pump, replace the O-ring (inlet to cylinder).

(3) When the fresh water pump and pump body and/or fresh water pump and pump plate

are disassembled, retighten to the specified torque.

9.3.4 Fresh water pump inspection

(1) Bearing unit inspection

Rotate the impeller smoothly. If the rotation is not smooth or abnormal noise is head

due to excessive bearing play or contact with other parts, replace the pump as an

assembly

(2) Impeller inspection

Check the impeller blade, and replace if damaged or corroded or if the impeller blade is

worn due to contact with pump body.

(3) Check the holes in the cooling water and bypass lines, clean out any dirt or other

foreign matter and repair as necessary.

(4) Replace the pump as an assembly if there is excessive water leakage due to

mechanical seal or impeller seal wear or damage.

(5) Inspect the fresh water pump body, clean off scale and rust, and replace if corroded.

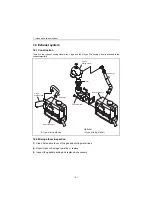

(6) Measure the outside clearance between the impeller and the pump body, by pushing

the impeller all the way towards the body, and inserting a thickness gauge diagonally

between the impeller and the body.

Measure the side clearance between the impeller and the plate by placing a straight-

edge against the end of the pump body and inserting a thickness gauge between the

impeller and the straight-edge.

Measuring outside clearance between impeller and

pump body.

Tightening torque for pump

setting bolts

392-785 N•cm

(40-80 kgf•cm)

mm

Standard

Limit

Outside clearance between

impeller and body

0.3-1.1

1.5

Thickness gauge

Summary of Contents for 3YM20

Page 1: ...M9961 03E100 ...