2. Inspection and adjustment

42

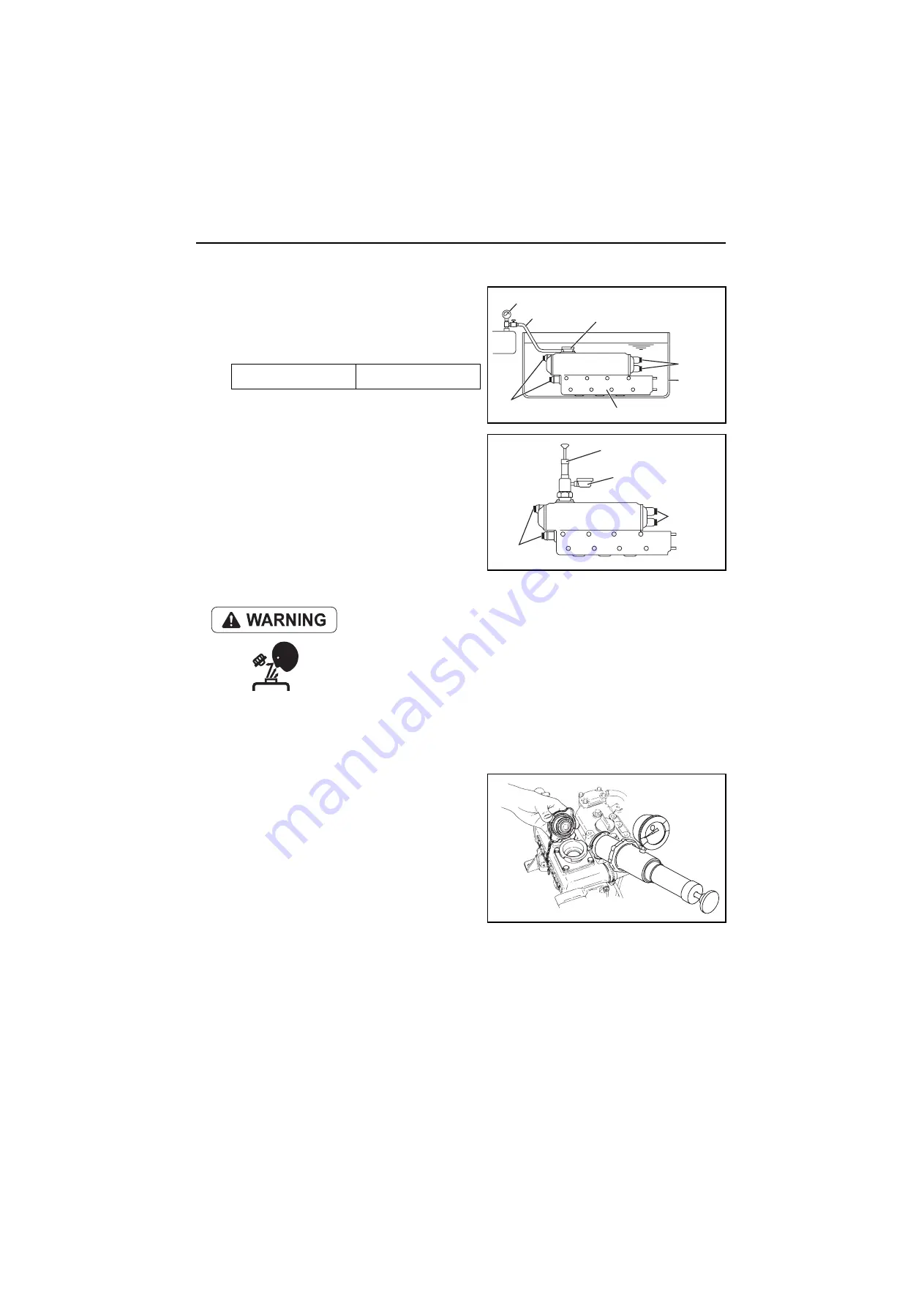

3) Heat exchanger body water leakage test

a) Compressed air/water tank test

Fit rubber covers on the fresh water and

seawater inlets and outlets. Place the heat

exchanger in a water tank, feed in compressed

air from the overflow pipe and check for any

(water) leakage, (air bubbles).

b) Use of the tester

Fit the fresh and seawater inlets and outlets with

rubber covers and fill the fresh water tank with

fresh water. Fit a pressure cap tester in place of

the pressure cap, operate the pump for one

minute and set the pressure at 0.15 Mpa (1.5

kgf/cm

2

, 21.33 lb/in.

2

). If there are any leaks the

pressure will not rise. If there are no leaks the

pressure will not fall.

4) Pressure cap inspection

Do not open the pressure cap while the engine is running or right after

stopping because high temperature steam will be blown out. Remove the

cap only after the water cools down.

a) Remove scale and rust and check the seat and seat valve, etc. for scratches or wear. Check the

spring for corrosion or settling. Replace if necessary.

[NOTE]

Clean the pressure cap with fresh water as it will not close completely if it is dirty.

b) Fit the adopter on the tester to the pressure cap.

Pump until the pressure gauge is within the

specified pressure range 0.074-0.103 MPa

(0.75-1.05 kgf/cm

2

) and note the gauge reading.

The cap is normal if the pressure holds for six

seconds. If the pressure does not rise, or drop

immediately, inspect the cap and repair or

replace as necessary.

Test pressure

0.20 MPa (2 kgf/cm

2

)

Pressure gauge

Rubber

cap

Tast tank

Rubber cap

Air hose

Filler cap

Heat exchanger

Pressure tester

Pressure gauge

Rubber cap

Rubber cap

Summary of Contents for 3YM20

Page 1: ...M9961 03E100 ...