7800 SERIES EC7890A,B/RM7890A,B RELAY MODULE

65-0204–1

21

Table 5. Flame Signal (See Fig. 18).

Flame Detector

Flame Signal Amplifier

Minimum Acceptable

Steady dc Voltage

a

Maximum Expected

dc Voltage

Flame Rod Photocell

C7012A,C

R7847A,B

b

1.25 Vdc

5.0 Vdc at the Keyboard

Display Module.

C7012E,F

R7847C

c

or

C7015A

R7848A,B

b

5.0 Vdc at a 1M ohm/voltmeter.

C7027A

C7035A

C7044A

R7849A,B

b

C7061A

R7861

d

C7076A,D

R7886A

e

a

This minimum or a stronger signal should easily be obtained if the detector is correctly installed and positioned to properly

sense the flame. This voltage must be obtained before completing checkout.

b

The flame amplifiers are Ampli-Check® type.

c

The flame signal amplifier circuitry is tested one-half second every five seconds during burner operation and shuts down the

burner if the amplifier fails (all installations). R7847C is for use with RM7890A,B only.

d

Requires use of separate step-down transformer. See Fig. 13.

e

R7886A is for use with RM7890A,B only.

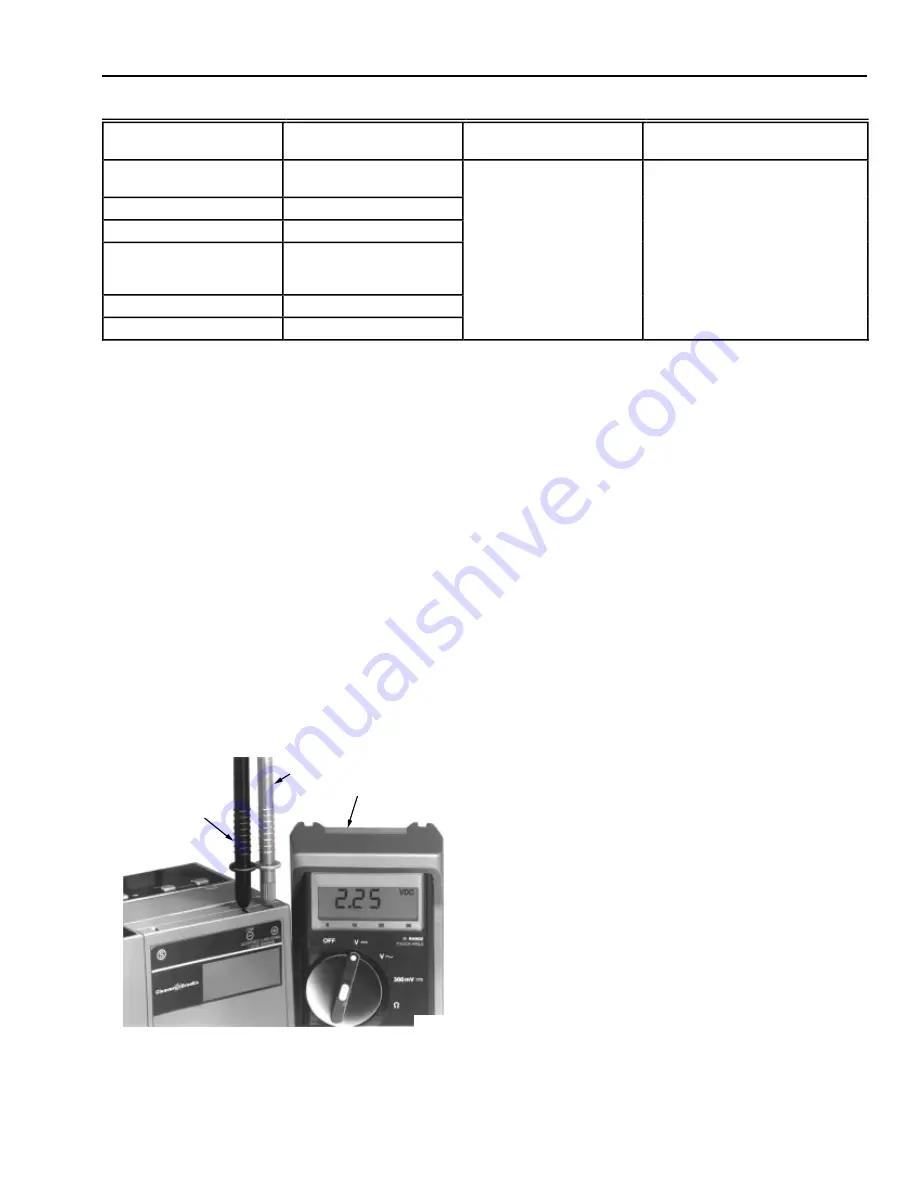

Flame Signal Measurement

Measure the flame signal at the appropriate times defined in

the following checkout tests. Read the flame signal Vdc at the

flame amplifier test jacks + and - (Com).

1

Use a 1M ohm/volt meter with a 0 to 10 Vdc capability.

2

Set the 1M ohm/volt meter to the 0 to 10 Vdc range.

3

Insert the positive (red) probe into the + jack of the

flame amplifier. Insert the negative (black) probe into

the - (Com) jack of the flame amplifier (see Fig. 18).

4

Allow a few seconds for the meter reading to stabilize.

5

If using Ampli-Check™ or shutter check amplifiers, read

the average stable voltage, disregarding the peaks and

valleys caused by the self-checking operation.

6

The meter reading must be as specified in Table 5 after

all tests are completed and all adjustments are made.

As an option, the flame signal can be checked by using the

optional Keyboard Display Module.

If the signal is unstable or less than the minimum acceptable

voltage, check the flame detector installation and circuitry.

1

Check the supply voltages at terminals 3 (L1) and L2

(N). Make sure the master switch is closed,

connections are correct, and the power supply is of the

correct voltage, frequency and is sinusoidal.

2

Check the detector wiring for defects including:

•

Deteriorated wire.

•

Incorrect connections.

•

Leakage paths caused by moisture, soot or

accumulated dirt.

•

Open circuits.

•

Short circuits.

•

Wrong type of wire.

3

For a flame rod, make sure:

•

Flame rod is properly located in the flame.

•

Ground area is large enough.

•

Temperature at the flame rod insulator is no

greater than 500

°

F (260

°

C).

4

For all optical detectors, clean the detector viewing

window and inside of the sight pipe as applicable.

5

With the burner running, check the temperature at the

detector. If it exceeds the detector maximum rated

temperature:

•

Add a heat block to stop conducted heat traveling

up the sight pipe.

•

Add a shield or screen to reflect radiated heat.

•

Add cooling (refer to sight pipe ventilation in the

detector Instructions).

6

Make sure that the flame adjustment is not too lean.

7

Make sure that the detector is properly sighting

the flame.

8

If necessary, resight or reposition the detector.

Initial Proved Pilot Lightoff Check

Perform this check on all installations that use a pilot. It

should immediately follow the preliminary inspection.

Fig. 18. Flame signal measurement.

NEGATIVE (-)

METER LEAD

POSITIVE (+)

METER LEAD

ONE

MEGOHM/VOLT

METER

M7383