7800 SERIES EC7890A,B/RM7890A,B RELAY MODULE

65-0204–1

8

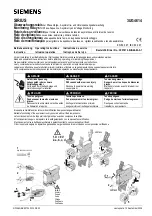

Fig. 4. Ultraviolet detectors

(Continued).

Fig. 5. Infrared detector.

PRINCIPAL TECHNICAL FEATURES

The 7890 provides all customary flame safeguard functions

while providing significant advancements in the areas of

safety, annunciation and system diagnostics.

Safety Shutdown (Lockout) Occurs If:

1

INITIATE PERIOD

a.

AC line power errors occurred, see Operation.

b.

Configuration jumpers have been changed (after

200 hours).

c.

Four minute INITIATE period has been exceeded.

2

STANDBY PERIOD

a.

Flame signal is present after 40 seconds.

b.

Ignition/intermittent pilot valve terminal is

energized.

c.

Internal system fault occurred.

d.

Main valve terminal is energized.

e.

Three second Flame Failure Response Time

(FFRT) Amplifier is installed and configuration

jumper is selected for relight (see Table 3).

C7076D

3

SAFE START CHECK (EXCEPT 7890C)

a.

Ignition/intermittent pilot valve terminal is

energized.

b.

Internal system fault occurred.

c.

Main valve terminal is energized.

4

PILOT FLAME ESTABLISHING PERIOD (PFEP)

a.

Ignition/intermittent pilot valve terminal is not

energized.

b.

Internal system fault occurred.

c.

Main valve terminal is energized.

d.

No flame present at end of PFEP.

5

RUN PERIOD

a.

Ignition terminal is energized.

b.

Internal system fault occurred.

c.

Main valve terminal is not energized.

d.

No flame present and configuration jumper is

selected for lockout.

e.

Pilot valve terminal is not energized.

SAFETY PROVISIONS

Internal Hardware Status Monitoring

The 7890 analyzes the integrity of the configuration jumpers

and internal hardware. The POWER LED will blink every four

seconds, signifying an internal hardware check.

Closed Loop Logic Test

The test verifies the integrity of all safety critical loads,

terminals 8, 9 and 10. If the loads are not energized properly;

ie, the main valve terminal is powered during STANDBY, the

7890 will lockout on safety shutdown. The 7890 must react to

input changes but avoid the occurrence of

nuisance

shutdown events. Signal conditioning is applied to line

voltage inputs to verify proper operation in the presence of

normal electrical line noise such as transient high voltage

spikes or short periods of line dropout. Signal conditioning is

tolerant of synchronous noise (line noise events that occur at

the same time during each line cycle).

15/16 [24] DIA.

2 (51)

1 (25)

1 INCH NPT

15/16–18 UNC

(2 EACH)

M5084A

2-1/2

(64)

6-7/32

(158)

6-19/32

(168)

2-5/32

(55)

11-13/16 (300)

7-13/16 (198)

1-27/32

(47)

5-13/16 (147)

5-13/16

(147)

C7015

APERTURE

BUSHING WITH

MAGNIFYING LENS

COLLAR, 3/4-14 NPSM

INTERNAL THREADS

3/4-14

NPSM

3/4-14 NPSM

INTERNAL

THREADS

HEAT BLOCK

CELL MOUNT

M1982A

2 LEADS IN A

48 INCH (1.2 METER)

FLEXIBLE CONDUIT

2-3/4

(70)

1-1/4

(32)

1-5/8 (41)

1-1/16 (27)

1-1/4

(32)