For Service Engineer

Service Information

SI1604009E-002= S20, S10, M20, M10 and D10 installation procedures

6/34

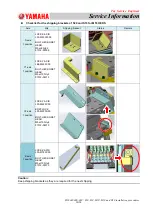

3.3 Carry in machines and equipment

Carry in a machine and necessary equipment with great care to avoid accidents.

Protect the floor to avoid damaging it. (

Plastic tiles especially need protection.

Prepare curing sheets.

)

When operating lifting equipment such as a hand lifter;

Pay attention to the center of gravity of the machine.

Do not lift it up excessively.

Handle the hand lifter with care.

If damaging

the customer’s possessions (the floor, the building, etc.) while carrying in the

machine to the installation site;

Promptly let the customer know and seek for their directions.

Otherwise it may cause a serious problem later on.

Take some

pictures of the damage

. (

Make sure to get t

he customer’s permission before

doing so.

)

Remove plastic wrapping from the machine.

After moving the machine to near the production line or the entrance of the clean room, remove the

plastic wrappings from the machine and the accessories.

3.4 Remove the shipping brackets

See

“Checklist for the shipping brackets” for the procedure of removing the shipping brackets

of the machine located temporarily.

Checklist for the shipping brackets of M20, M10 and D10

Axis

Qty

Shipping bracket

Status

Remark

X-axis

1 position

LOCK,X-AXIS

LE6-M220Y-00

BOLT,HEX,SOKET

HEAD

M5 × L10 Qty:2

91312-05010

Y-axis

2 positions

LOCK,Y-AXIS

LE6-M260Y-00

LE6-M260Y-10

BOLT,HEX,SOKET

HEAD

M5 × L10 Qty:4

91312-05010

Z-axis

1 position

LOCK,Z-AXIS

4-head LE6-M710Y-50

6-head LE6-M710Y-60

BOLT,HEX,SOKET

HEAD

M4 × wL15 Qty:2

91312-04015

Brackets vary

depending on the

head configuration.